Method for extracting and purifying vindoline

A purification method and the technology of ventolin, applied in the direction of organic chemistry, etc., can solve the problems of unsuitable industrial production, low content of ventolin, complicated extraction steps, etc., achieve less time consumption, increase content and yield, and meet market demands. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

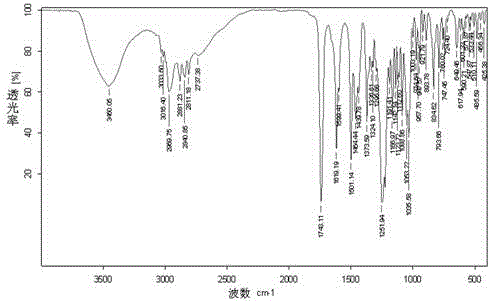

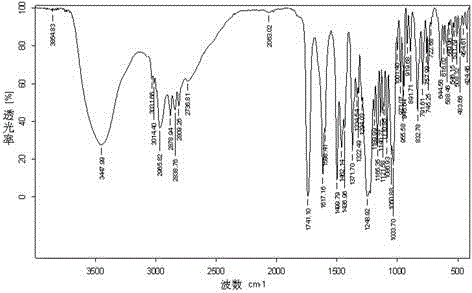

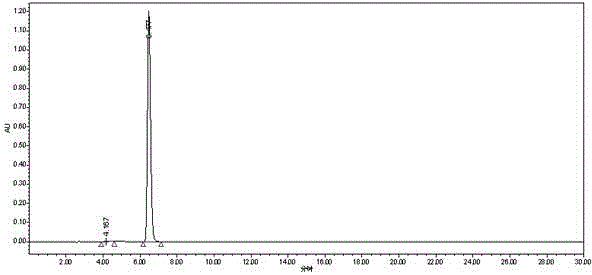

Image

Examples

Embodiment 1

[0039] Using fresh whole periwinkle (including root) as raw material, extract and isolate Wendolin according to the following method:

[0040] 1. Extraction and preparation of the crude product of Vendolin:

[0041] (1) Take 100kg of the whole periwinkle plant, add it to 850kg of 5wt% sodium chloride aqueous solution, soak it in ultrasonic for 15 minutes, then take out the periwinkle and put it directly into the cold air with a flow rate of 6.5m / s at -20°C for 40 minutes to freeze-dry. The periwinkle was crushed after freeze-drying.

[0042] (2) Add the periwinkle powder of the whole plant treated in step (1) into 300kg of water, adjust the pH to 1.5 with phosphoric acid, soak in ultrasonic for 3 hours, filter the filtrate, adjust the pH of the filtrate to 8-9 with ammonia water, and adjust the pH , apply high pressure to the filtrate, and spray it from the top of the extraction tank in the form of a spray at a speed of 180 ml / s. The ratio is 4.8:1, the filtrate and the extr...

Embodiment 2

[0052] 1. Extraction and preparation of the crude product of Vendolin:

[0053] Extract the crude product of Vendolin according to the method of Example 1, the difference is: the volume ratio of the filtrate to the extractant in step (2) is 5.5:1, and the extractant is n-bromopropane and ethanol with a volume ratio of 10:0.5 The mixture; in step (4), the volume ratio of dichloromethane and ethyl acetate is 10: 5. The mass of the obtained Wendolin crude product was 50.5g, the yield was 0.505‰, and the HPLC detection purity was 75.5%.

[0054] 2. The refinement of Wendolin:

[0055] Add 50.5g of the crude product of Vendolin to 151.5ml of a mixture of methanol, diethyl ether, petroleum ether and ethyl acetate with a volume ratio of 1:3:0.5:0.5, sonicate at room temperature for 5min, and wait for crystals to form, then incubate at -18°C After standing at low temperature for 24 hours, the crystallization was carried out. The obtained crystals were suction filtered at -18°C and...

Embodiment 3

[0057] The refined ventolin was extracted according to the method of Example 1, except that when refining the ventolin, the volume ratio of methanol, diethyl ether, petroleum ether and ethyl acetate was 1:3.5:0.3:0.6. The obtained high-purity ventolin was 37.1 g, and its purity was 99.5% as detected by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com