Pervaporation-normal pressure rectification integrated process for separating dimethyl carbonate and methanol

A technology of dimethyl carbonate and atmospheric distillation, which is applied to the preparation of organic carbonates, the separation/purification of hydroxyl compounds, the purification/separation of carbonates/haloformates, etc., to reduce energy consumption and simplify production The effect of low process and operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

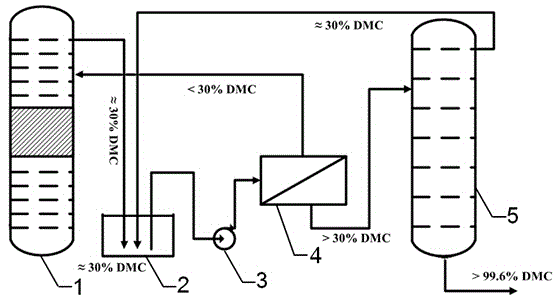

[0024] like figure 1 As shown, the azeotropic mixture of dimethyl carbonate and methanol is obtained at the top of reactive distillation column 1, the temperature is 64°C, the content of dimethyl carbonate is 30% (by mass fraction, the same below), and the content of methanol is 70% . The azeotropic mixture first enters the buffer tank 2, and then is transported to the pervaporation membrane system 4 by the liquid delivery pump 3 at 40°C, and contacts with the polydimethylsiloxane-polyvinylidene fluoride composite membrane. The pervaporation membrane system 4 includes a membrane module, a condenser and a vacuum pump, and the downstream side of the membrane is evacuated by a vacuum pump to maintain a vacuum degree of 100Pa. Due to the difference in pervaporation membrane selectivity for methanol and dimethyl carbonate adsorption, the pervaporation process breaks the methanol-dimethyl carbonate azeotropic equilibrium, and the retentate side is condensed by the condenser to obta...

Embodiment 2

[0026] like figure 1As shown, the azeotropic mixture of dimethyl carbonate and methanol is obtained at the top of the reactive distillation column 1, and the temperature is 64°C. The azeotropic mixture first enters the buffer tank 2, and then uses the liquid delivery pump 3 to transport to In the pervaporation membrane system 4, it is in contact with polydimethylsiloxane-polyvinylidene fluoride-nano titanium dioxide composite membrane. The pervaporation membrane system 4 includes a membrane module, a condenser and a vacuum pump, and the downstream side of the membrane is evacuated by a vacuum pump to maintain a vacuum degree of 2000Pa. Due to the difference in pervaporation membrane selectivity for methanol and dimethyl carbonate adsorption, the pervaporation process breaks the methanol-dimethyl carbonate azeotropic equilibrium, and the retentate side is condensed by the condenser to obtain a concentration of dimethyl carbonate of 10.3 wt% feed liquid a, feed liquid b with a ...

Embodiment 3

[0028] The azeotropic mixture of dimethyl carbonate and methanol is obtained at the top of the reactive distillation column 1, and the temperature is 64°C. The azeotropic mixture first enters the buffer tank 2, and then is transported to the pervaporation membrane by the liquid delivery pump 3 at 20°C In system 4, contact with a polydimethylsiloxane-silica-zirconia support layer composite membrane that is preferentially permeable to methanol. The pervaporation membrane system 4 includes a membrane module, a condenser and a vacuum pump, and the downstream side of the membrane is evacuated by a vacuum pump to maintain a vacuum degree of 10100 Pa. Due to the difference in pervaporation membrane selectivity for methanol and dimethyl carbonate adsorption, the pervaporation process breaks the methanol-dimethyl carbonate azeotropic equilibrium, and the retentate side is condensed by the condenser to obtain a concentration of dimethyl carbonate of 48.4 wt% feed liquid a, feed liquid b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com