Forging forming process of large thick-walled head with support and nozzle

A forming process and head technology, which is used in the field of forging and forming of large thick-walled heads, can solve the problems of large deformation resistance at the nozzle, difficult to compact the center, and complicated manufacturing, so as to reduce the production cycle and manufacturing cost. The effect of continuous fiber and less stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

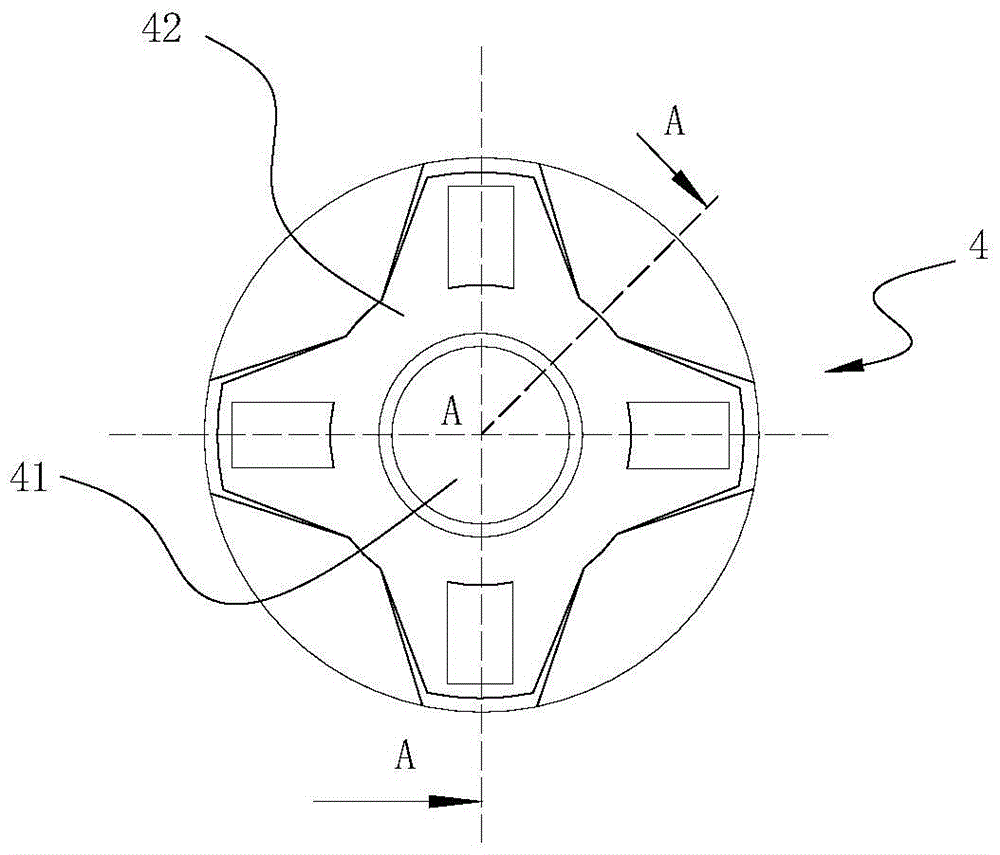

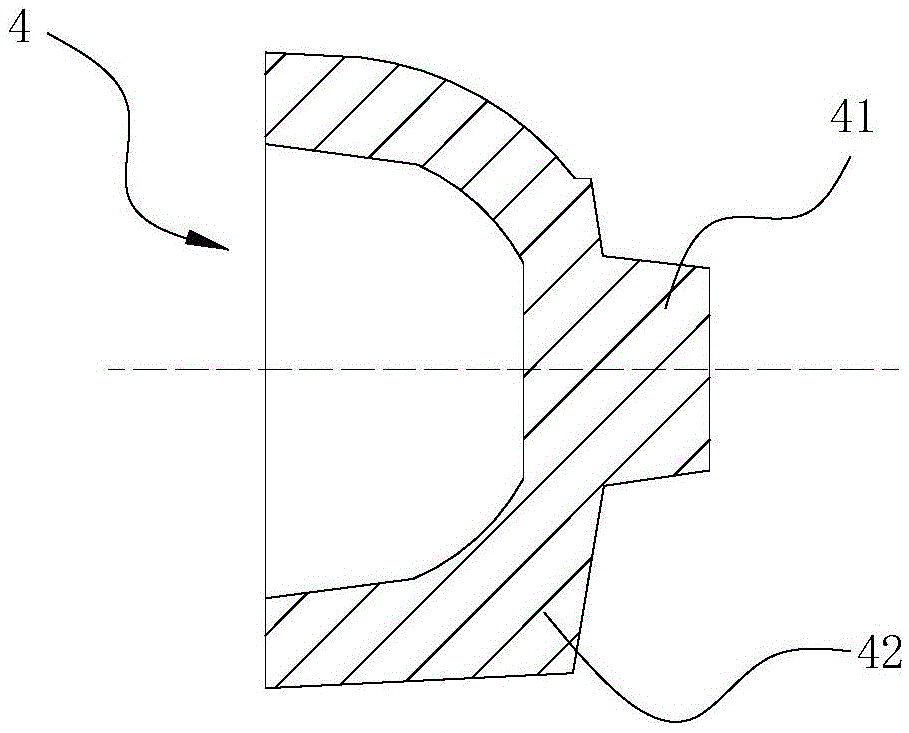

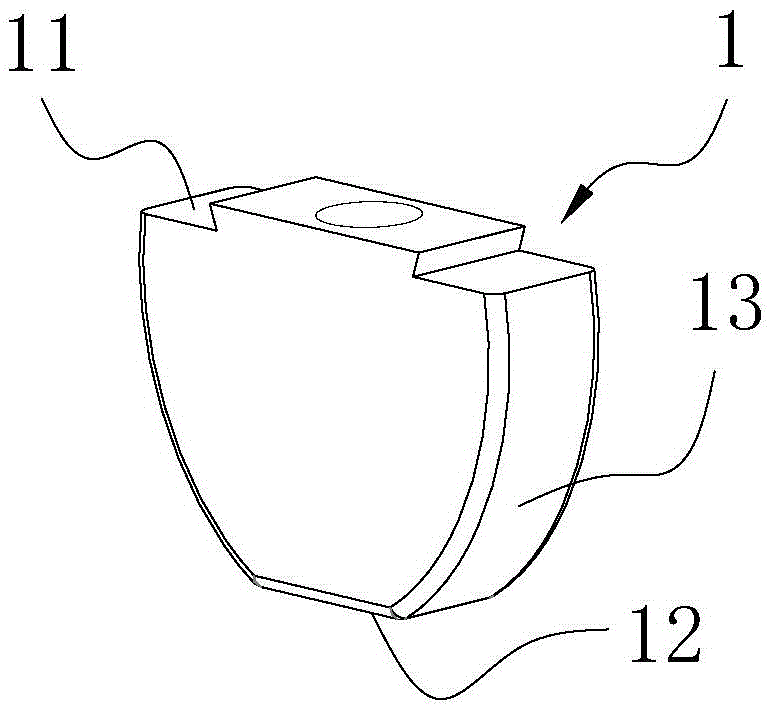

[0046] One-time forming of large thick-walled heads with cross supports and long nozzles; such as figure 1 As shown, the large thick-walled head with a cross support and a long nozzle has an inner chamber radius SR of 1350 mm, a wall thickness of 158 mm, a nozzle length of about 670 mm, and a large head with a straight section height of 330 mm. In the overall manufacturing process of forgings, the outer spherical surface is manufactured with cross supports. Its specific manufacturing steps are as follows:

[0047] (1) Manufacture corresponding copying lower die 2 and forging upper punch 1 according to the design size of the large thick-walled head with cross support and long nozzle; the size of the mold blank can be filled through computer simulation.

[0048] (2) Heating a 157-ton steel ingot to above 1200°C, carrying out compaction forging after heat preservation, and forging into a square billet 3 with a side length of 2200mm in a regular quadrilateral section, and perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com