Method and device for granulating melted material

A material and equipment technology, used in the field of molten material granulation, can solve the problems of the shell part and other machine parts to which the particles adhere, internal turbulence, etc., and achieve high material production capacity, uniform flow behavior, and good cooling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

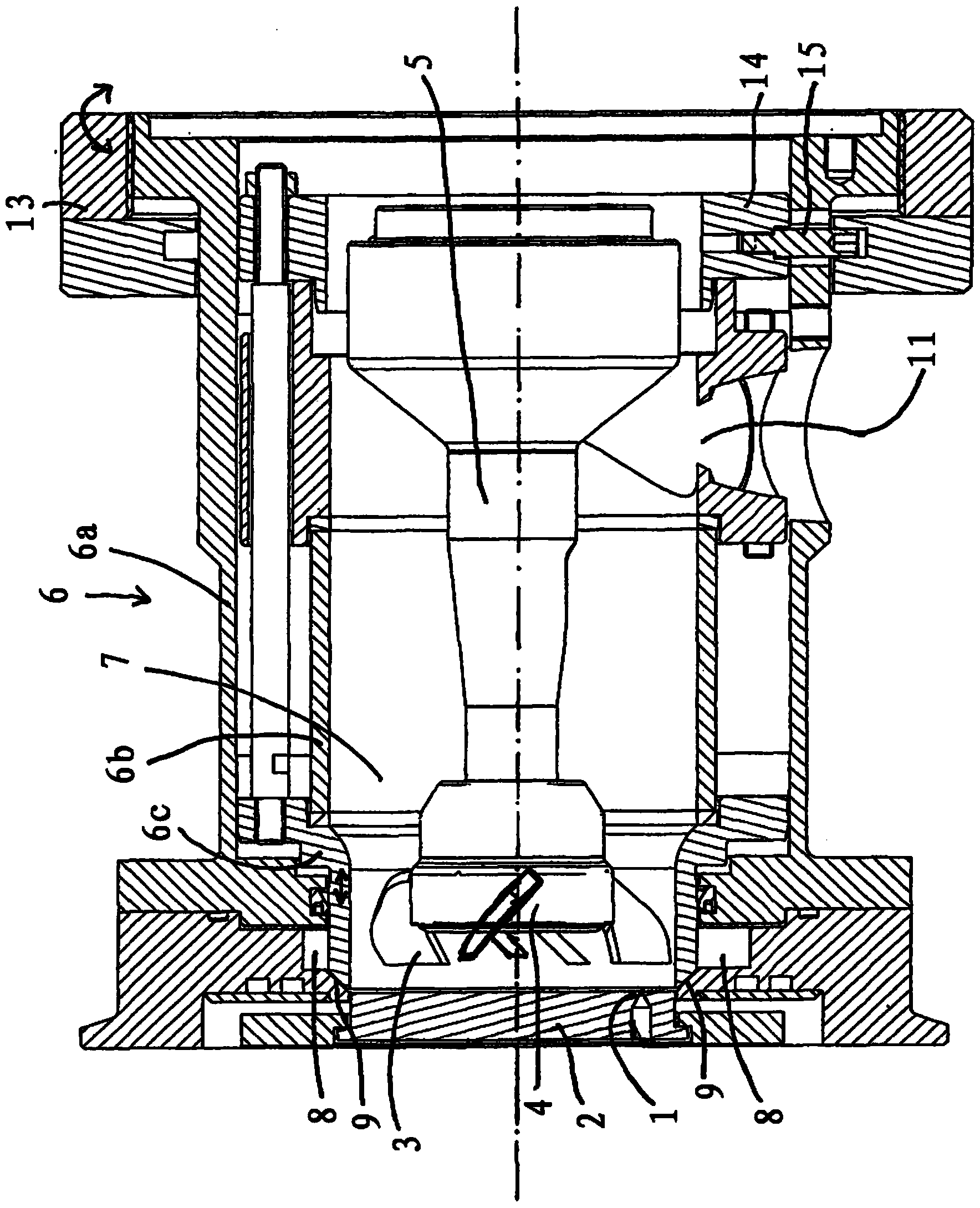

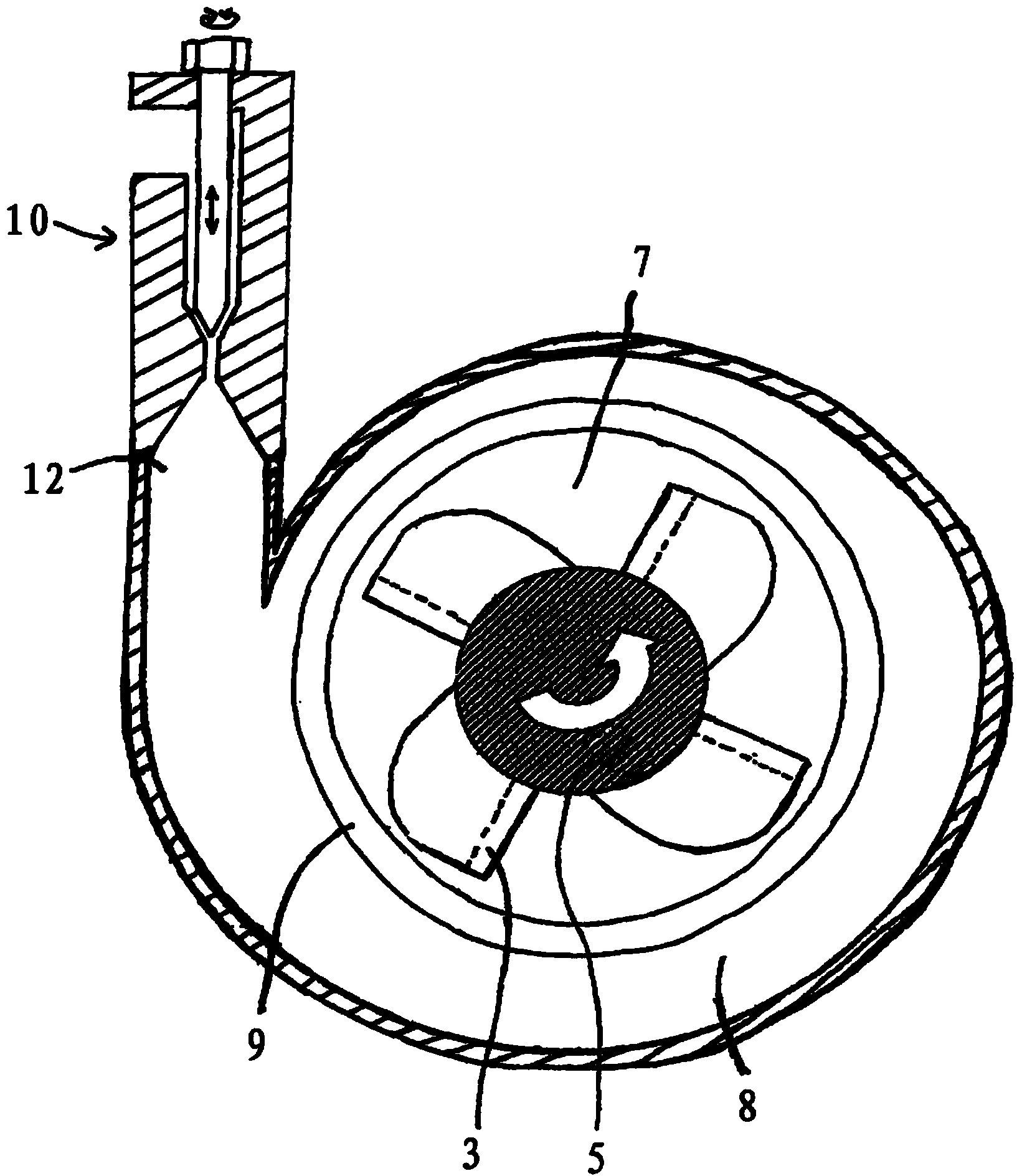

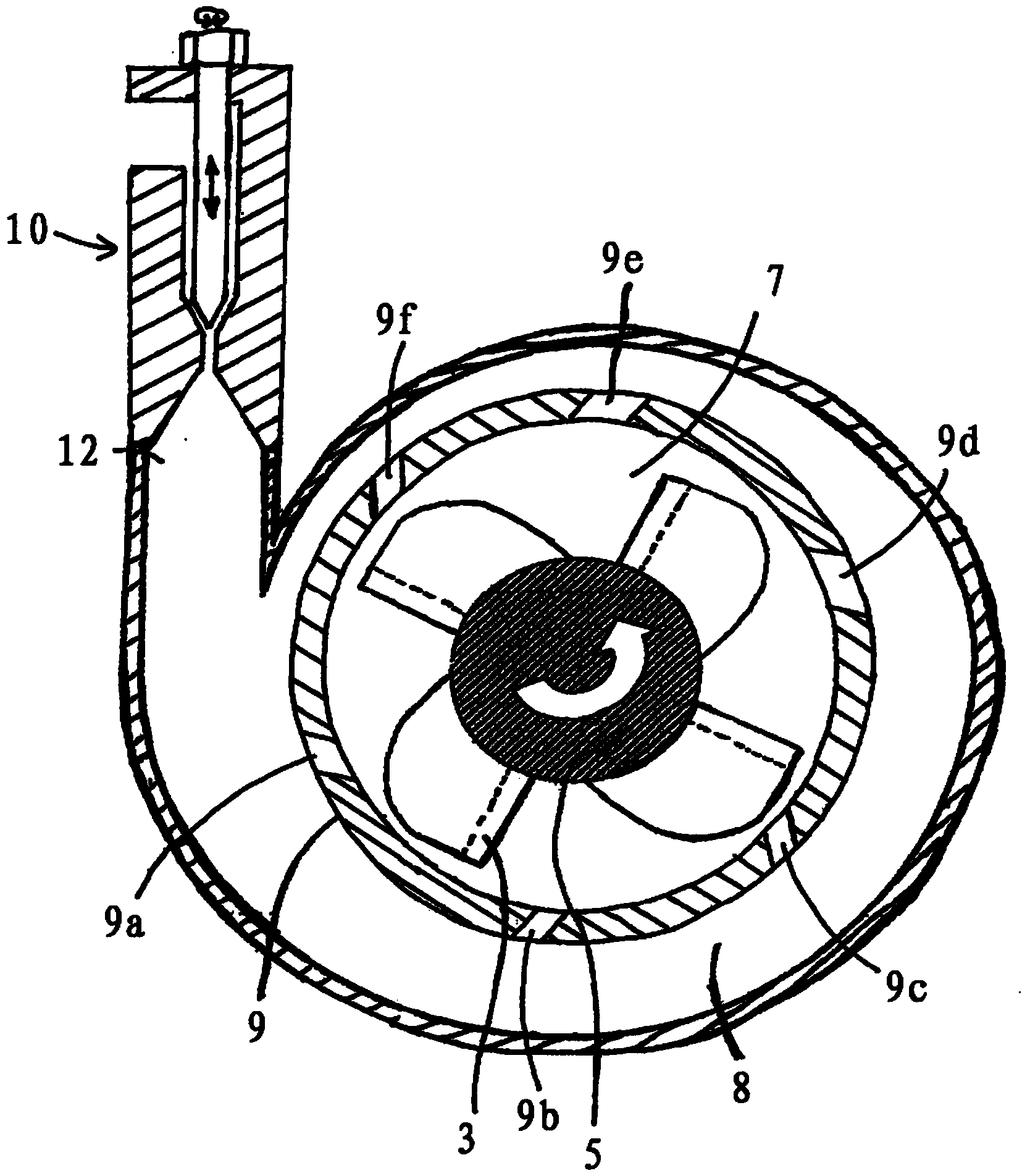

[0039] figure 1 Schematically shows a longitudinal sectional view of a granulation plant for a molten material, eg a pharmaceutical molten material, which is discharged from a nozzle 1 on a perforated plate 2 .

[0040] figure 1 The granulation device shown schematically in has a perforated plate 2 with nozzles 1 arranged thereon, wherein the arrangement of the nozzles 1 is substantially rotationally symmetrical, and the rest of the design of the plant is also rotationally symmetrical or substantially rotationally symmetrical. Such as figure 1 Associated with the perforated plate 2 is shown a cutter device with at least one blade 3 comprising a blade seat 4 on a blade shaft 5 . The cutter device is driven by a motor ( figure 1 not shown in ) so that at least one blade 3 passes over the nozzle 1 on the perforated plate 2 and cuts particles such as molten material of medicine discharged from the nozzle 2 during this time. The molten mass can be melted in a conventional manne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com