Oil bath-based natural circulation and heat pipe-coupled battery pack thermal management system

A thermal management system and natural circulation technology, which is applied in the field of thermal management control of vehicle power batteries, can solve problems such as electrolyte dryness, failure, expansion, fire, stacking heat, explosion, etc., to achieve significant arc extinguishing and insulation effects, and increase heat dissipation Strength, the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

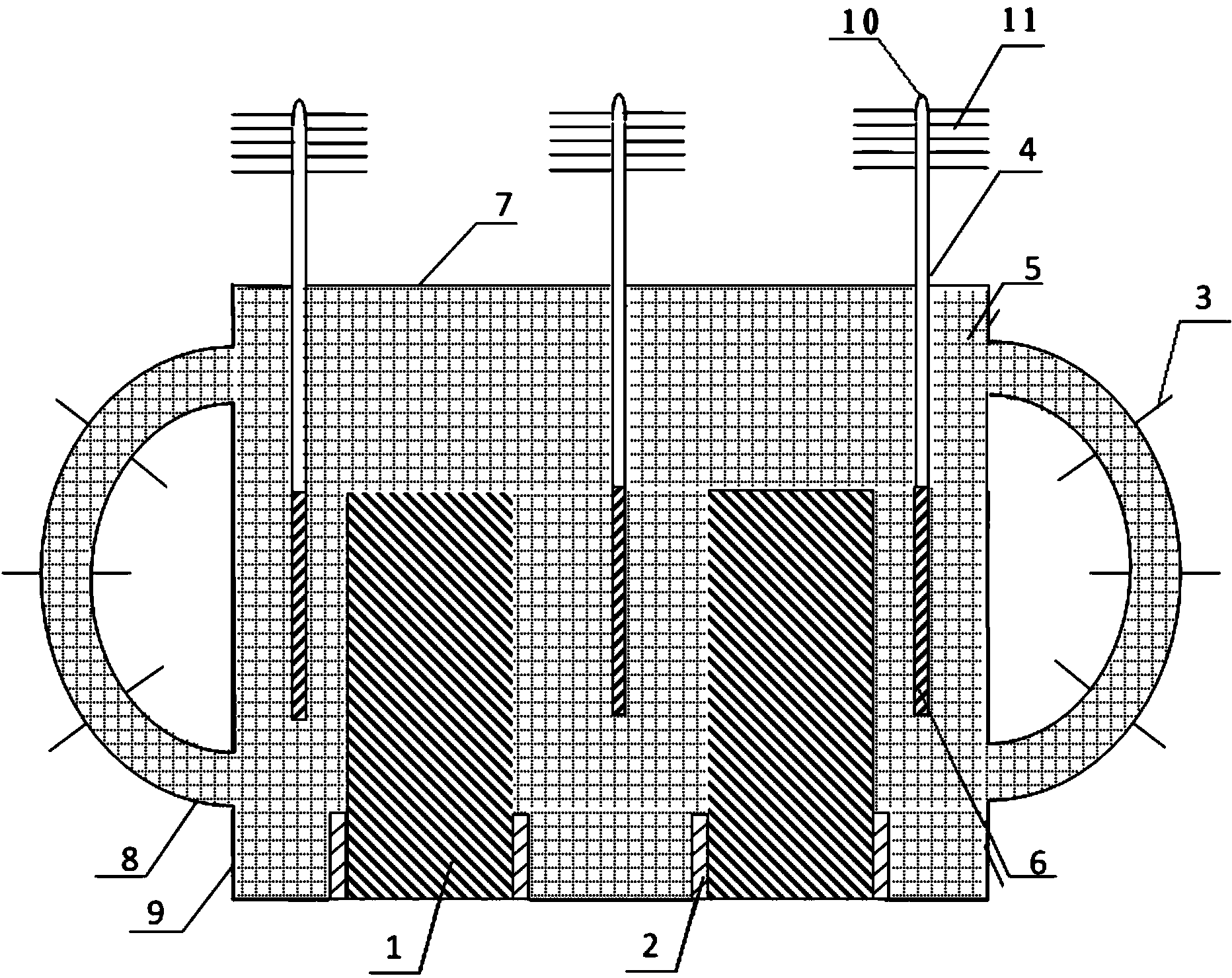

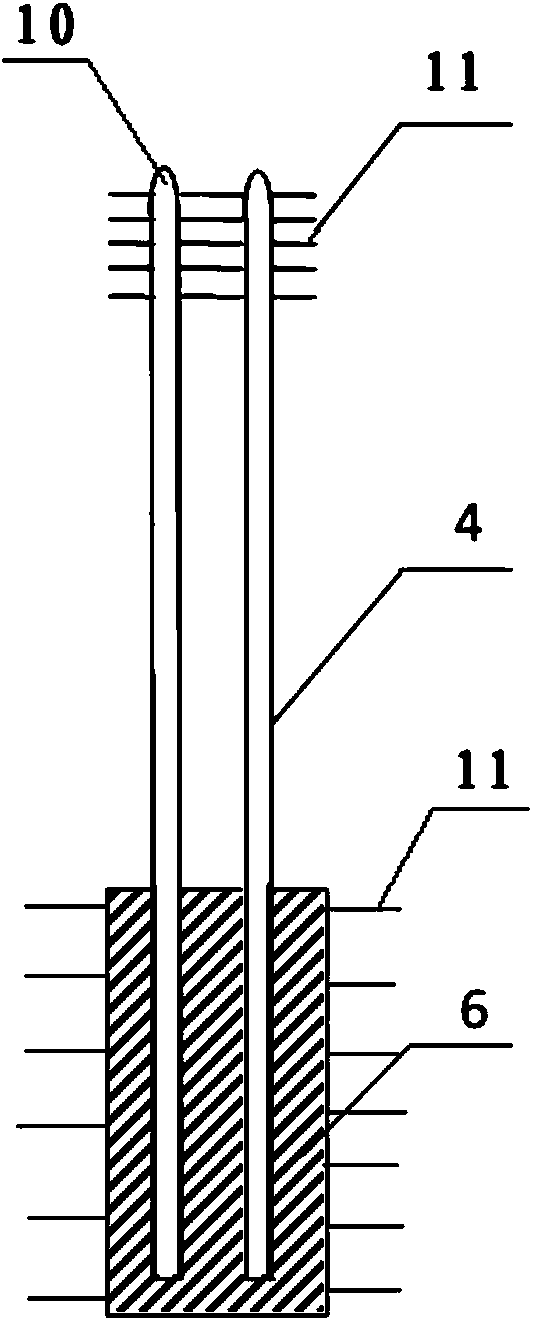

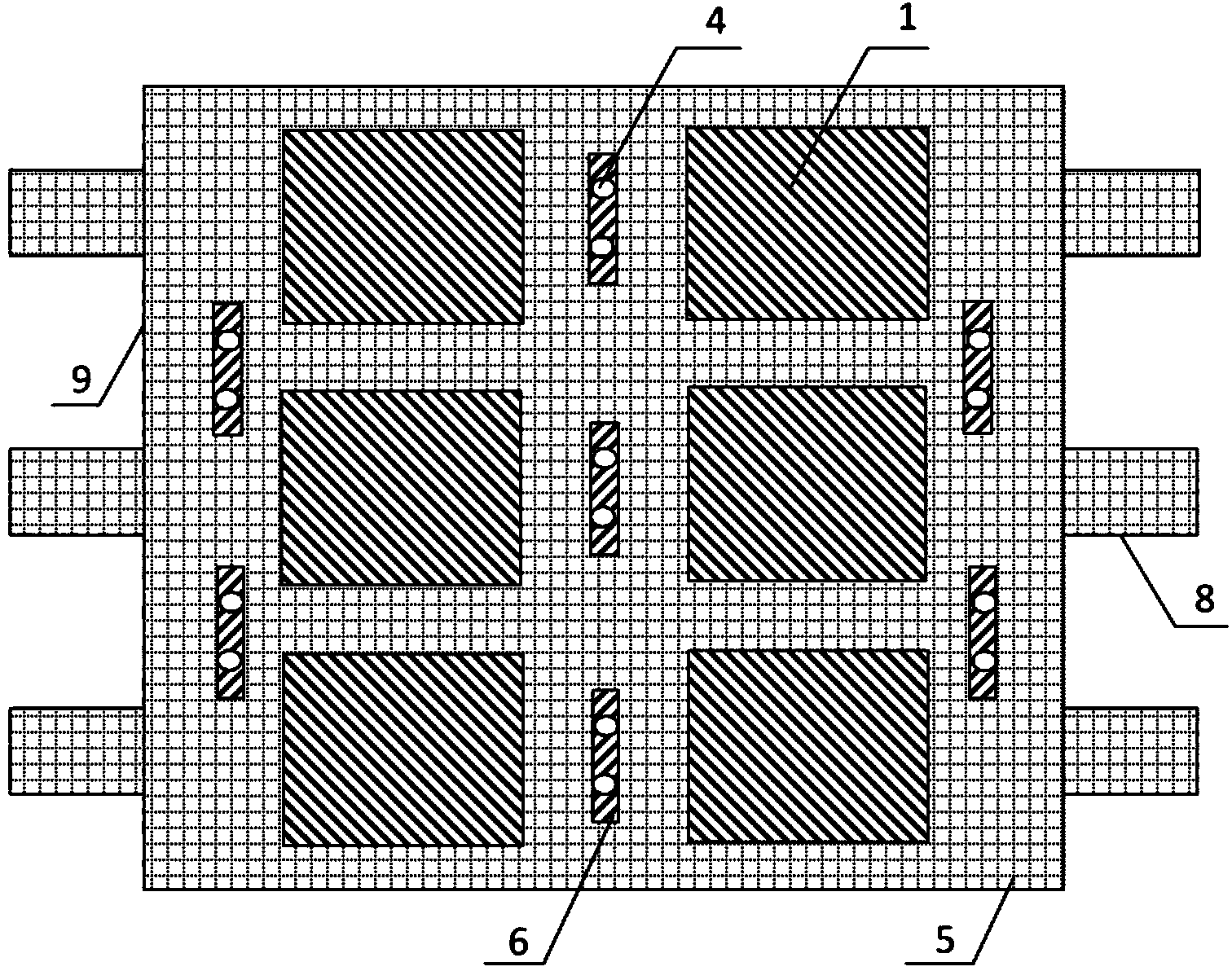

[0024] Specific implementation method: A battery pack thermal management system based on oil bath natural circulation coupled with heat pipes in this embodiment includes a plurality of single batteries 1, a plurality of battery card slots 2, a box top cover 7 and a casing 9, The bottom surface of the housing 9 is provided with a plurality of battery slots 2, and each single battery 1 is fixed in the housing 9 through a battery slot 2, and the battery slots 2 position the single battery 1 to ensure that the single battery The position of the body battery 1 will not move, and a plurality of single cells are connected in series and parallel to form a power battery pack, and the top cover 7 of the box body is installed on the casing 9 to form a power battery box; The battery pack thermal management system coupled with heat pipes also includes multiple heat pipes 4 and multiple circulation pipes 8. The single battery 1 is vacuum-sealed. The evaporation section 6 of the heat pipe 4 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com