Ultra-hard particle-enhanced martensitic wear-resistant steel plate and manufacturing method thereof

A technology of superhard particles and wear-resistant steel plates, which is applied in the field of alloy steel, can solve the problems of poor welding performance and processing performance of high-hardness wear-resistant steel, and difficulty in meeting equipment manufacturing requirements, so as to improve wear resistance and solve wear resistance The effect of resolving outstanding contradictions with processability and weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

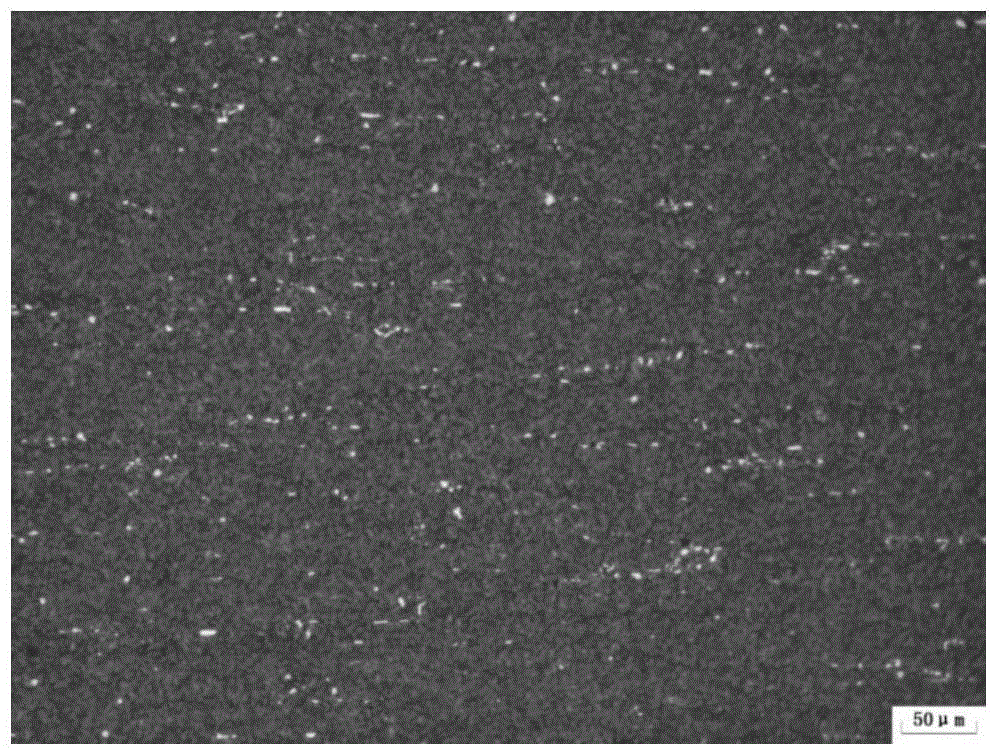

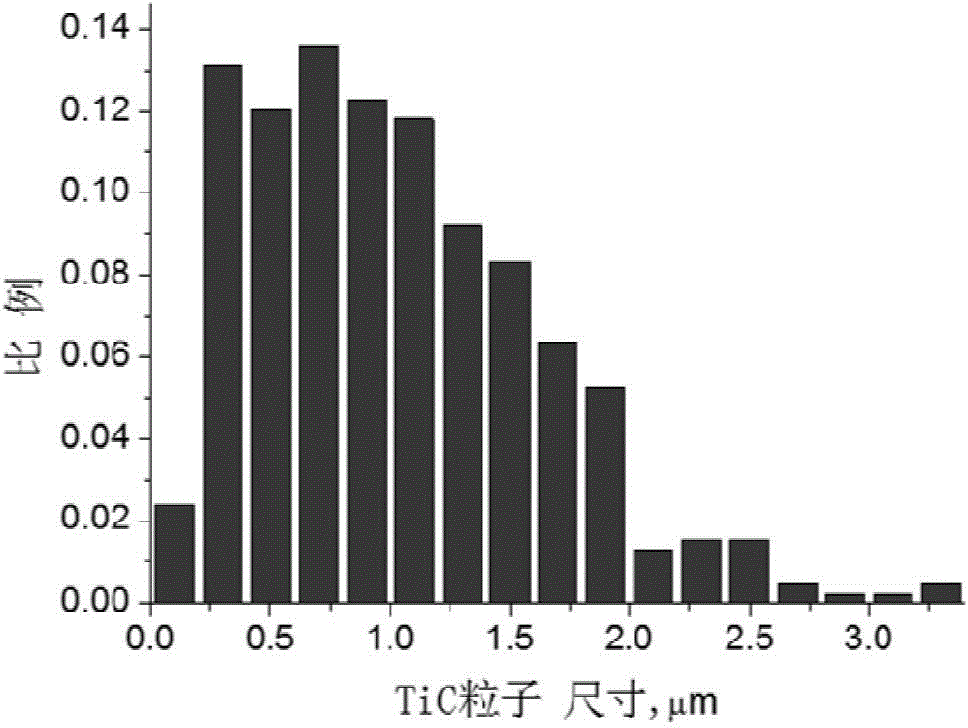

Image

Examples

Embodiment 1

[0027] Embodiment 1: The chemical composition of the present invention is C: 0.33; Si: 0.43; Mn: 0.54; Cr: 0.82; Ni: 0.55; Mo: 0.31; Ti: 0.61; Cu: 0.32; ; S: 0.005; P: 0.005; the balance is Fe and unavoidable impurities. Manufacturing process: converter smelting, LF refining, RH refining, slab continuous casting, rolling by medium and heavy plate rolling mill, heating furnace heating temperature 1200 ℃, finishing rolling temperature 860 ℃, rolling thickness 30mm, air cooling after rolling. Heat treatment process: austenitizing temperature 880°C, holding time 0.5 hours, water quenching to room temperature, then tempering at 200°C for 1 hour and air cooling to room temperature.

Embodiment 2

[0028] Embodiment 2: The chemical composition of the present invention is C: 0.31; Si: 0.48; Mn: 0.92; Cr: 0.91; Ni: 0.51; Mo: 0.32, Ti, 0.58, Cu: 0.35; ; S: 0.005; P: 0.015; the balance is Fe and unavoidable impurities. Manufacturing process: converter smelting, LF refining, slab continuous casting, rolling by medium and heavy plate rolling mill, heating furnace heating temperature 1180 ℃, finishing rolling temperature 900 ℃, rolling thickness 60mm, air cooling after rolling. Heat treatment process: austenitizing temperature 900°C, holding time 0.5 hours, water quenching to room temperature, then tempering at 200°C for 1 hour and air cooling to room temperature.

Embodiment 3

[0029] Embodiment 3: The chemical composition of the present invention is C: 0.38; Si: 0.45; Mn: 0.85; Cr: 0.82; Ni: 0.58; Mo: 0.38; Ti: 0.58; Cu: 0.45; ; S: 0.005; P: 0.015; the balance is Fe and unavoidable impurities. Manufacturing process: converter smelting, LF refining, slab continuous casting, rolling by medium and heavy plate rolling mill, heating furnace heating temperature 1200 ℃, finishing rolling temperature 880 ℃, rolling thickness 40mm, air cooling after rolling. Heat treatment process: austenitizing temperature 900°C, holding time 0.5 hours, water quenching to room temperature, then tempering at 200°C for 1 hour and air cooling to room temperature.

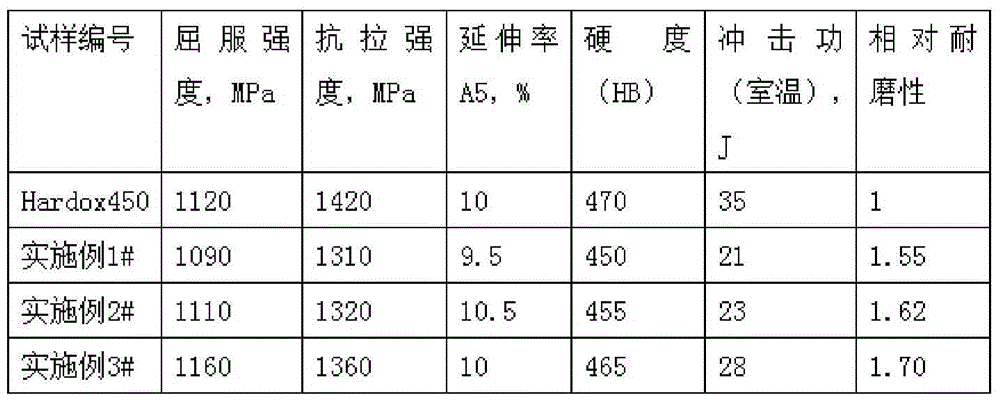

[0030] Examples of the present invention and Hardox450 mechanical properties and wear resistance testing results are shown in Table 1.

[0031] Table 1 Example of the present invention and Hardox450 mechanical properties and wear resistance testing results

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com