A class of polyimide containing four major substituent side groups and twisted non-coplanar structure and preparation method thereof

A polyimide, non-coplanar technology, which is applied in the field of polyimide and its preparation containing four major substituted side groups and twisted non-coplanar structures, can solve the problem of low gas separation performance and polyimide composition Difficult membrane and other problems, to achieve good thermal stability and gas separation performance, simple synthesis route, improve the effect of film formation performance and gas separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Add 28.492g (0.05mol) of 2,2'-bis(3,5-dibromo-4-fluorophenyl) to a 1000ml three-necked flask equipped with mechanical stirring, condensing device and nitrogen protection Sulfone and 37.986g (0.20mol) of 4-trifluoromethylphenylboronic acid, 2.311g (0.002mol) of tetrakis (triphenylphosphine) palladium, 42.396g (0.40mol) of sodium carbonate, 170g of water, 85ml of toluene and 85ml of ethylene glycol dimethyl ether, stirred at room temperature (25°C) for 10 minutes, then heated to reflux, reacted for 8 hours, evaporated the organic solvent, and filtered the crude product, washed with water and dried, and used N,N- Further recrystallization of dimethylformamide gave the intermediate bisfluoro compound 2,2'-bis[3,5-bis(4-trifluoromethylphenyl)-4-fluorophenyl]sulfone as a white powder, producing The rate was 81% (calculated based on the conversion rate of 2,2'-bis(3,5-dibromo-4-fluorophenyl)sulfone).

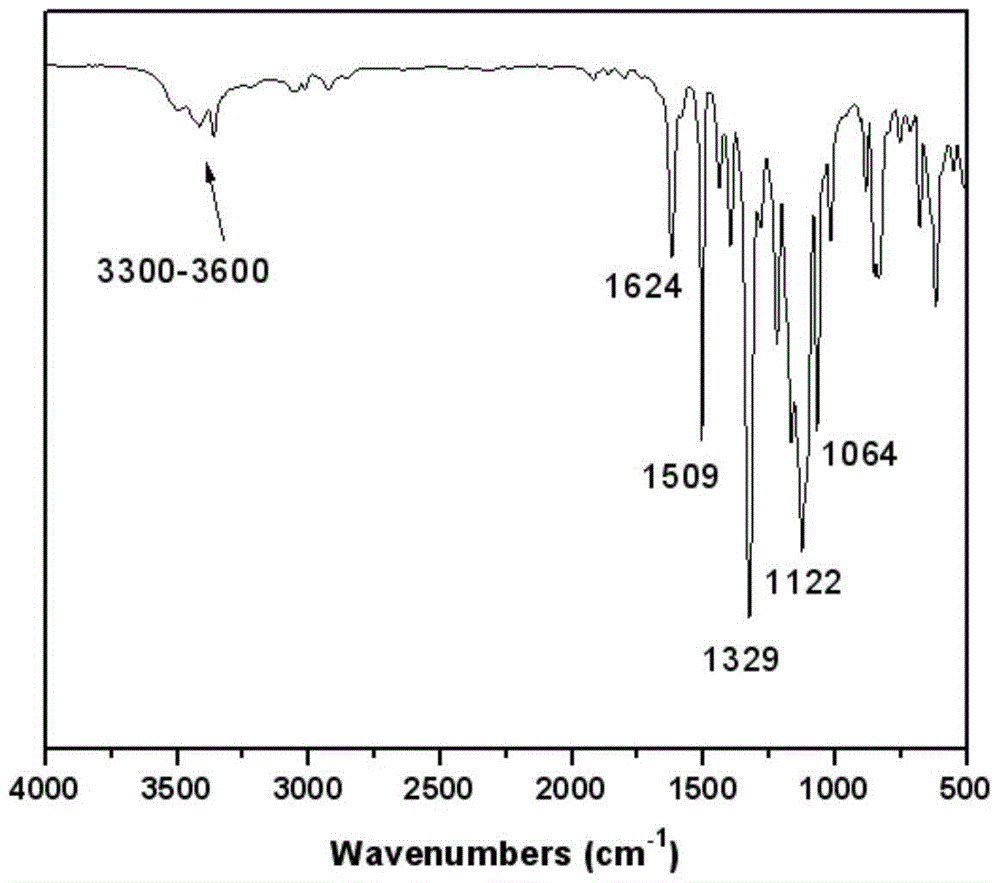

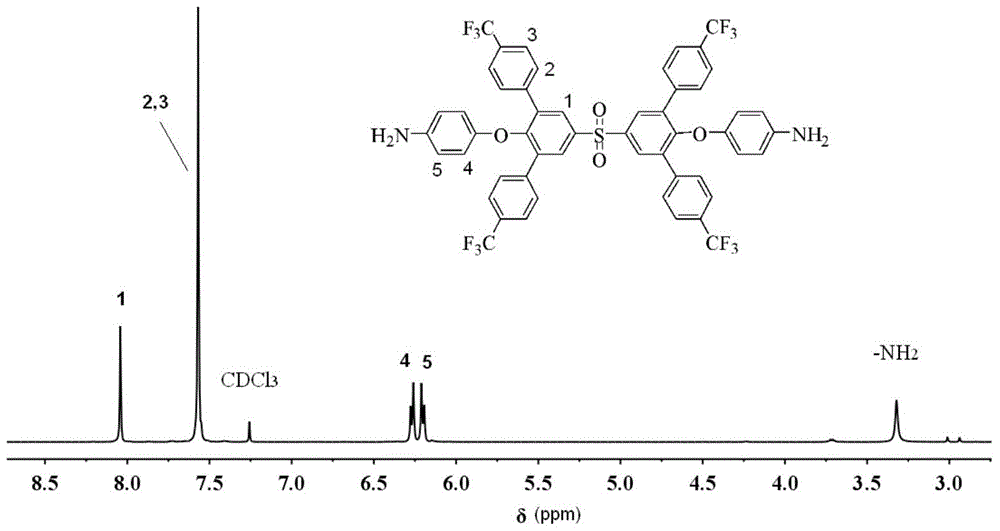

[0031] The melting point of the 2,2'-bis[3,5-bis(4-trifluoromethylphen...

Embodiment 2

[0037] In a dry 50ml three-necked round-bottomed flask with nitrogen, add 3.0266g (3mmol) of 2,2'-bis[3,5-bis(4-trifluoromethylphenyl)-4 obtained in Example 1 -(4-aminophenoxy)phenyl]sulfone and 0.8827 (3mmol) aromatic dianhydride monomer (taking biphenyltetralic acid dianhydride as an example), then add 23.5g N-methylpyrrolidone, room temperature (25°C) After stirring and reacting for 12 hours, the temperature was further raised to 180° C., and after stirring and reacting with water for 20 hours through a nitrogen stream, the reaction solution was poured into ethanol to obtain a fibrous polyimide polymer with a yield of 98% (with 2, Conversion rate calculation of 2'-bis[3,5-bis(4-trifluoromethylphenyl)-4-(4-aminophenoxy)phenyl]sulfone).

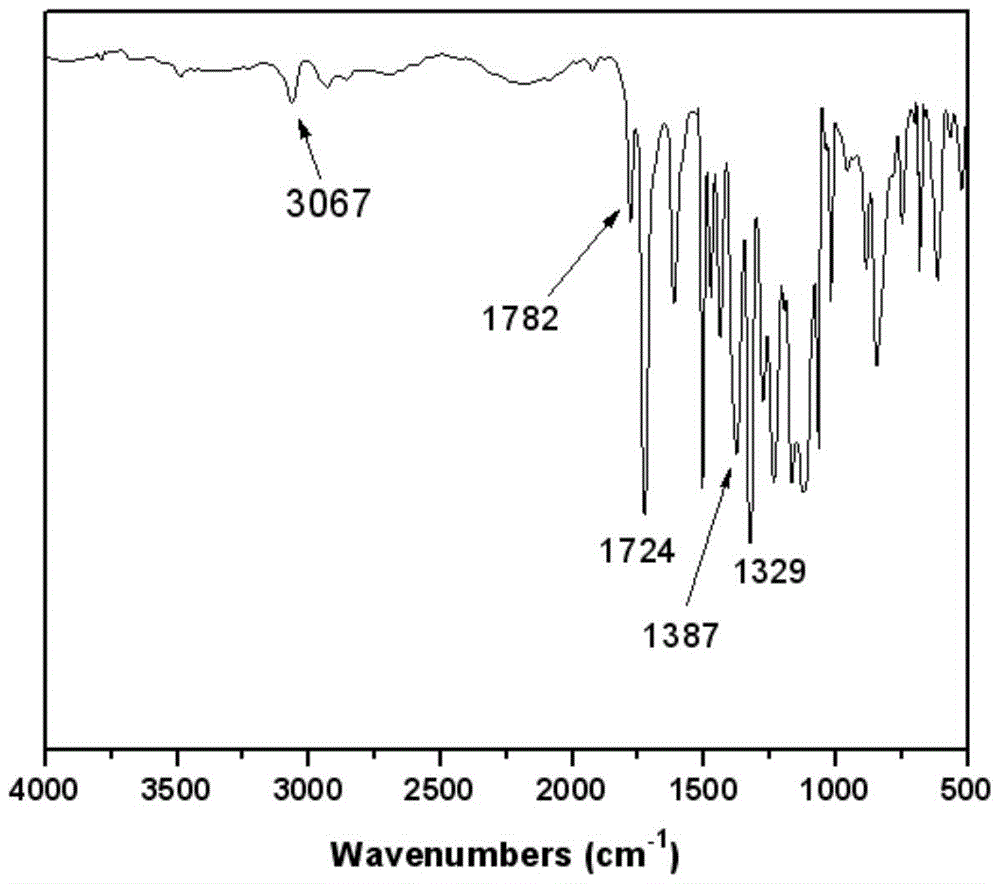

[0038] FT-IR(KBr)ν / cm -1 :3067,1782,1724,1387,1329,1178,1129. 1 HNMR (CDCl 3 ,400MHz)δ:8.04(s,4H),7.26(s,16H),6.27(d,4H),6.20(d,4H),3.31(s,4H). image 3 , Figure 4 shown.

Embodiment 3

[0040] In a dry 50ml three-necked round-bottomed flask with nitrogen, add 3.0266g (3mmol) of 2,2'-bis[3,5-bis(4-trifluoromethylphenyl)-4 obtained in Example 1 -(4-aminophenoxy)phenyl]sulfone and 0.930 (3mmol) aromatic dianhydride monomer (taking diphenyl ether tetra-acid dianhydride as an example), then add 35.1g N-methylpyrrolidone, room temperature (25 ℃ ) after stirring and reacting for 24 hours, further warming up to 200° C., and stirring and reacting with water for 8 hours through nitrogen flow, the reaction solution was poured into ethanol to obtain a fibrous polyimide polymer with a yield of 98% (with 2 , 2'-bis[3,5-bis(4-trifluoromethylphenyl)-4-(4-aminophenoxy)phenyl]sulfone conversion calculation).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com