Polygonal pyramid quick-plugging sealed auger stem

A technology of auger pipe and polygonal pyramid, which is applied in drill pipe, drill pipe, drilling equipment and other directions, can solve the problems of poor use conditions, disconnection of drill pipe, poor reliability, etc., achieve high processing accuracy and processing efficiency, and improve the overall Bending resistance, suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

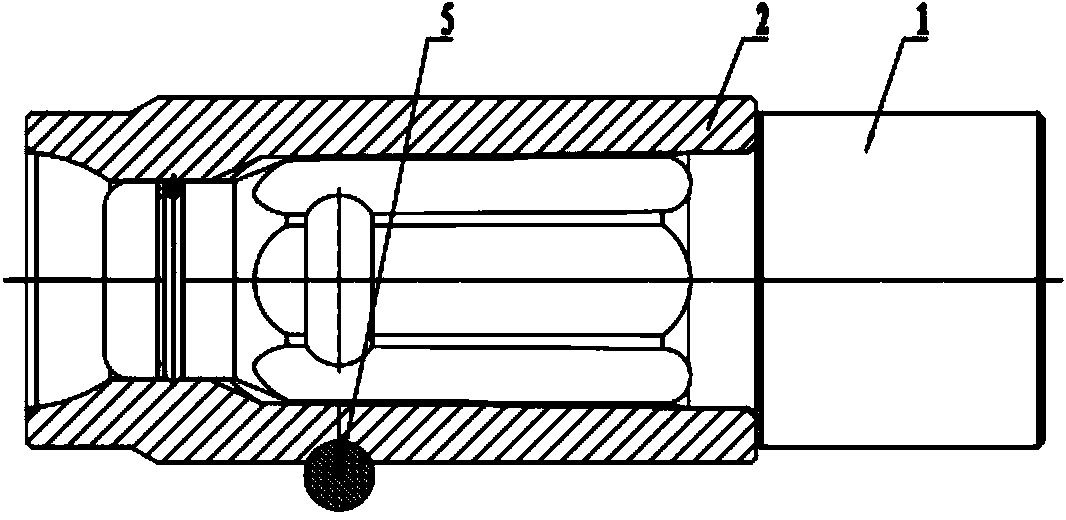

[0022] Such as figure 1 As shown, the multi-pyramid fast plug-in sealed auger drill pipe is composed of five parts: male joint 1, female joint 2, rod body 3, helical fin 4, and U-shaped connecting pin 5. The male joint 1 and female joint 2 are welded by friction The two ends of the rod body 3 are respectively welded to form the drill rod body, and the helical fins 4 are wound on the outer surface of the drill rod body, and the helical fins can be single-headed or multi-headed.

[0023] Such as figure 2 As shown, when the drill pipe is inserted into the connection, the axial movement is restricted by the U-shaped connecting pin 5. The pin body is a U-shaped long and short side structure, and the short side is embedded in the drill pipe joint, and the long side is fixed by bolts.

[0024] The male and female connectors have a multi-pyramid matching structure. The number of cones is 3-9, and the taper is 0-15°. ability.

[0025] Longer shoulders are provided on the axial ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com