Cold resistant artificial leather shining under illumination

A technology of artificial leather and pearl powder, applied in the field of artificial leather, can solve the problems of not being able to satisfy people, not emitting light, and not being able to effectively resist the cold, etc., and achieve the effect of resisting the cold, good warmth retention effect, and simple fabric structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

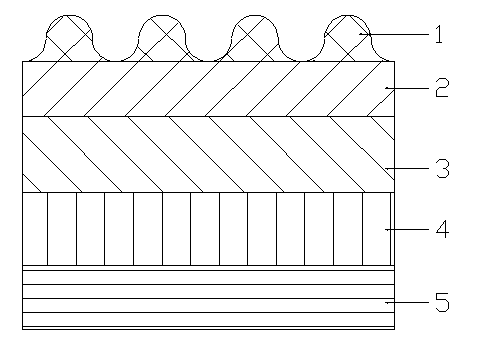

[0016] see figure 1 , the present invention is a kind of cold-resistant artificial leather that is illuminated and shines, and it comprises the surface layer 4 and the base layer 5 that are bonded to each other, and the pearl powder layer 3 is bonded on the surface layer 4, and the pearl powder layer 3 is bonded There is a transparent film 2, and the diamond pattern 1 is pressed on the transparent film 2.

[0017] The base layer 5 is made of fabric, and the fabric used is composed of four layers of fabric layer, thermal insulation layer, cavity layer and surface layer from the inside to the outside, and the surface layer is composed of conductive fibers. Yarn and ordinary fiber yarn are interwoven, the ordinary fiber is cotton, hemp, wool, silk or chemical fiber, the thermal insulation layer is made of sponge, the fabric layer is placed on one side of the surface layer, and The surface layer is fixedly connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com