Neodymium-ytterbium codoped zirconium sulfide up-conversion fluorescent powder, as well as preparation method and applications thereof

A technology of co-doping and zirconium sulfide, which is applied in the field of phosphors to reduce the probability of non-radiative transitions, improve the up-conversion luminous efficiency, and reduce the particle size of the powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

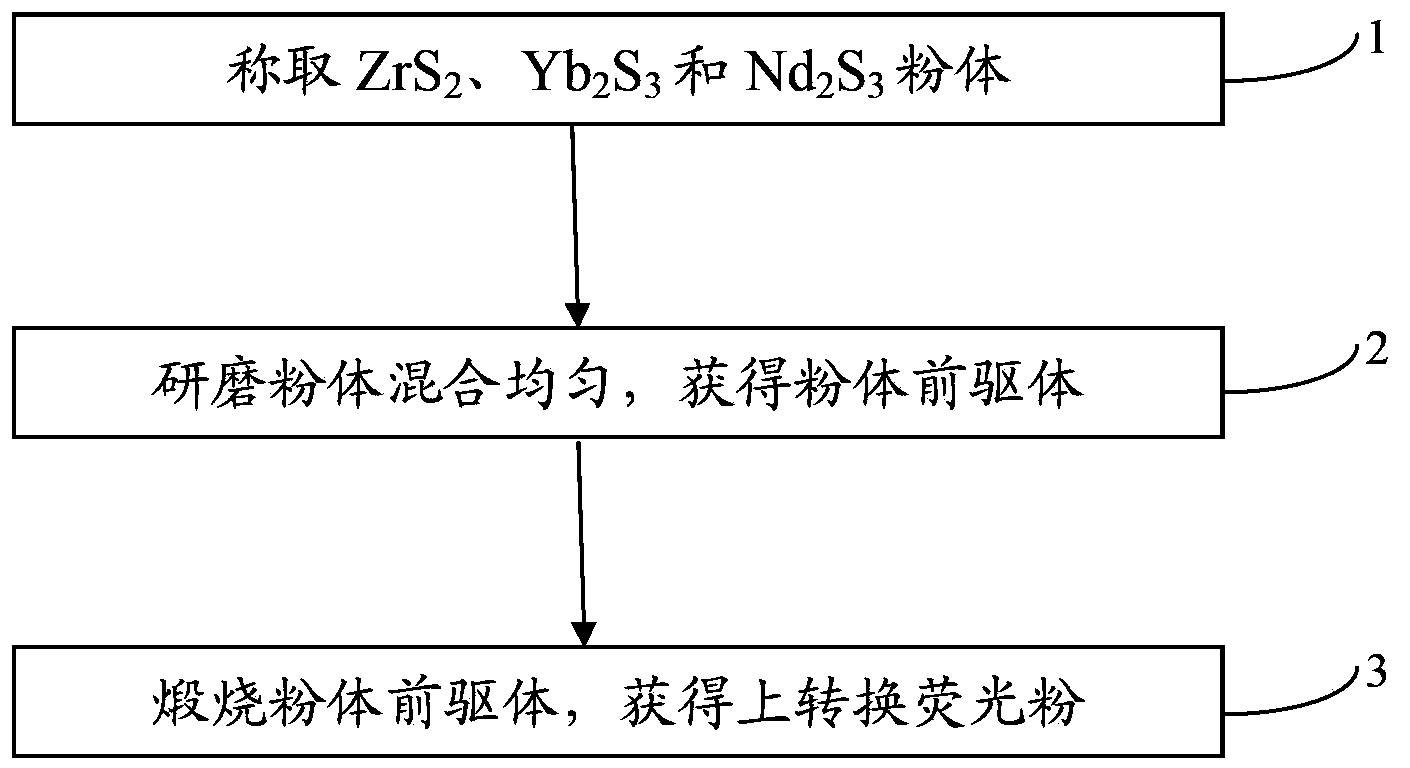

[0035] combine figure 1 As shown in the flow chart of the preparation process of neodymium ytterbium co-doped zirconium sulfide up-conversion phosphor, the invention provides a preparation method of neodymium ytterbium co-doped zirconium sulfide up-conversion phosphor, comprising the following steps:

[0036] (1) Weigh ZrS respectively 2 (0.96mmol), Yb 2 S 3 (0.03mmol) and Nd 2 S 3 (0.01mmol) powder;

[0037] (2) Place the powder obtained in (1) in a corundum mortar and grind for 40 minutes to obtain a uniformly mixed powder precursor;

[0038] (3) Put the powder precursor obtained in (2) into a muffle furnace, burn at 900°C for 3 hours, cool to 200°C and keep it warm for 2 hours, then take it out after cooling to room temperature with the furnace to obtain a bulk material ;

[0039] (4) Pulverize the bulk material obtained in (3) to obtain the neodymium-ytterbium co-doped zirconium sulfide up-conversion phosphor P1, whose general chemical formula is Zr 0.92 S 2 : 0.0...

Embodiment 2

[0048] A preparation method of neodymium ytterbium co-doped zirconium sulfide up-conversion phosphor, comprising the following steps:

[0049] (1) Weigh ZrS respectively 2 (0.93mmol), Yb 2 S 3 (0.005mmol) and Nd 2 S 3 (0.03mmol) powder;

[0050] (2) Place the powder obtained in (1) in a corundum mortar and grind for 20 minutes to obtain a uniformly mixed powder precursor;

[0051] (3) Put the powder precursor obtained in (2) into a muffle furnace, burn at 800°C for 0.5 hours, cool to 100°C and keep it warm for 0.5 hours, and then cool to room temperature with the furnace to obtain a bulk material;

[0052] (4) Pulverize the bulk material obtained in (3) to obtain Nd-ytterbium co-doped zirconium sulfide up-conversion phosphor P2, whose general chemical formula is Zr 0.93 S 2 : 0.01Yb 3+ , 0.06Nd 3+ .

Embodiment 3

[0054] A preparation method of neodymium ytterbium co-doped zirconium sulfide up-conversion phosphor, comprising the following steps:

[0055] (1) Weigh ZrS respectively 2 (0.896mmol), Yb 2 S 3 (0.05mmol) and Nd 2 S 3 (0.002mmol) powder;

[0056] (2) Place the powder obtained in (1) in a corundum mortar and grind for 60 minutes to obtain a uniformly mixed powder precursor;

[0057] (3) Put the powder precursor obtained in (2) into a muffle furnace, burn at 1000°C for 4 hours, cool to 300°C and keep it warm for 3 hours, and then cool to room temperature with the furnace to obtain a bulk material;

[0058] (4) Pulverize the bulk material obtained in (3) to obtain Nd-ytterbium co-doped zirconium sulfide up-conversion phosphor P3, whose general chemical formula is Zr 0.896 S 2 : 0.1Yb 3+ , 0.004Nd 3+ .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com