Wave-absorbing material, wave-absorbing substrate and manufacturing method

A technology of wave absorbing materials and substrates, applied in the field of wave absorbing materials, can solve the problems of low mechanical strength of wave absorbing materials and complex thickness of wave absorbing layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The wave-absorbing substrate is obtained by impregnating the para-aramid paper used as a reinforcing material sheet into the resin-based wave-absorbing material, and then at least heating the para-aramid paper, such as a baking process. Among them, the resin-based absorbing material is configured according to the following ratio:

[0069] Hongchang Electronic Materials Co., Ltd. model GEBR454A80 epoxy resin (solid content 80%, 20% acetone solvent) 125g

[0070] Taiwan Changchun Petroleum Resin Material Co., Ltd. model PF8090M62 phenolic resin (62% solid content, 38% acetone solvent) 40g

[0071] Carbonyl iron powder 203g

[0072] Acetone 40g

[0073] Wherein, the ratio of the phenolic hydroxyl equivalent of the phenolic resin to the epoxy equivalent of the epoxy resin is 1:1.

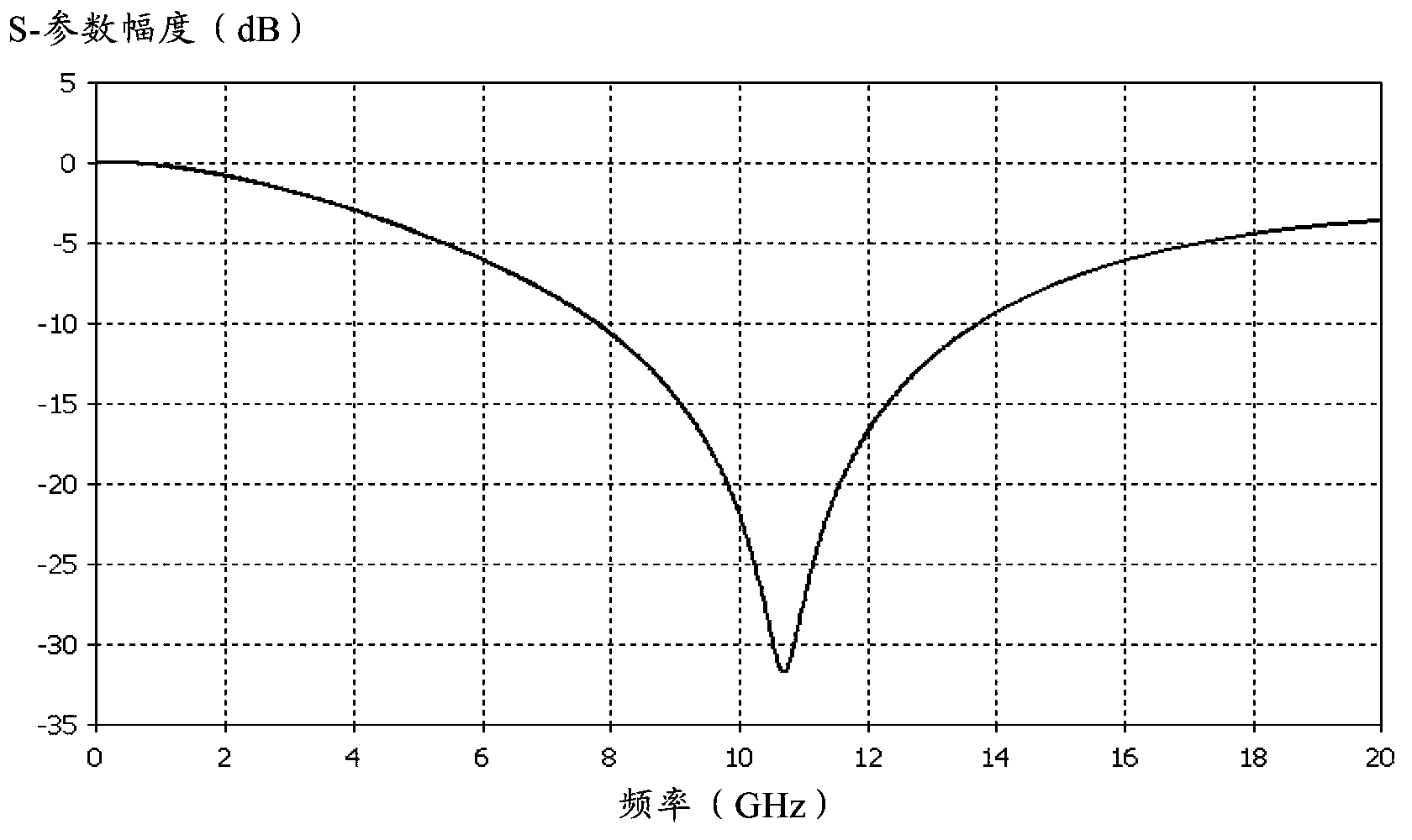

[0074] Preparation method: Stir epoxy resin, phenolic resin, carbonyl iron powder and acetone evenly to make a glue (for example, stir for about 2 hours); use Haotian Longbang's 0.05mm para-ar...

Embodiment 2

[0077] The wave-absorbing substrate is obtained by impregnating the para-aramid paper used as a reinforcing material sheet into the resin-based wave-absorbing material, and then at least heating the para-aramid paper, such as a baking process. Among them, the resin-based absorbing material is configured according to the following ratio:

[0078] Hongchang Electronic Materials Co., Ltd. model GEBR454A80 epoxy resin (solid content 80%, 20% acetone solvent) 125g

[0079] Taiwan Changchun Petroleum Resin Material Co., Ltd. model PF8090M62 phenolic resin (62% solid content, 38% acetone solvent) 40g

[0080] Carbonyl iron powder 253g

[0081] 1,2-Dimethylimidazole 0.0625g

[0082] Acetone 40g

[0083] Wherein, the ratio of the phenolic hydroxyl equivalent of the phenolic resin to the epoxy equivalent of the epoxy resin is 1:1.

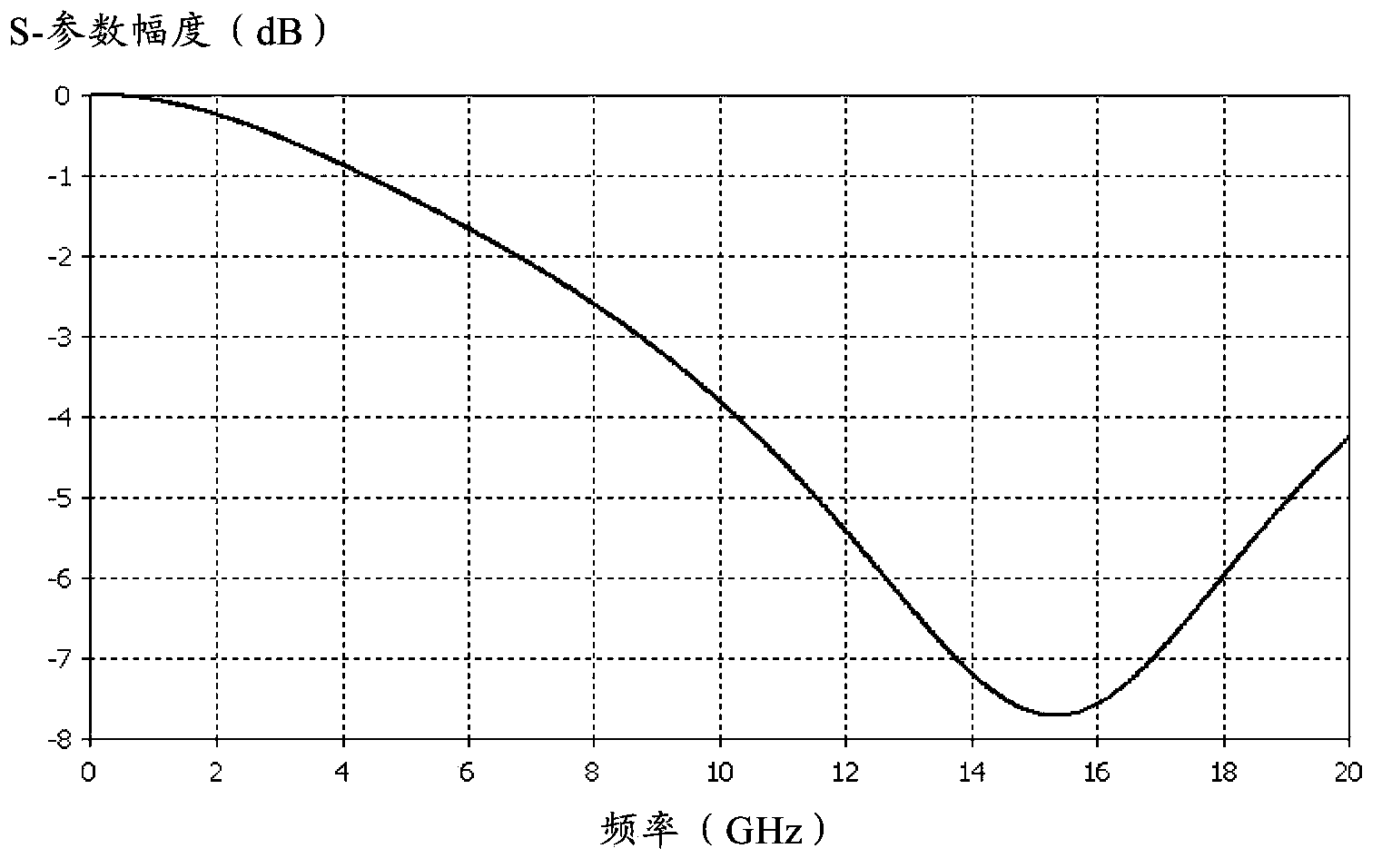

[0084] Preparation method: Stir epoxy resin, phenolic resin, carbonyl iron powder and acetone evenly, add dimethylimidazole and stir to make a glue (for...

Embodiment 3

[0087] The wave-absorbing substrate is obtained by impregnating the para-aramid paper used as a reinforcing material sheet into the resin-based wave-absorbing material, and then at least heating the para-aramid paper, such as a baking process. Among them, the resin-based absorbing material is configured according to the following ratio:

[0088] Hongchang Electronic Materials Co., Ltd. model is GEBR454A80 epoxy resin (80% solid content, 20% acetone solvent) 125g

[0089] Taiwan Changchun Petroleum Resin Material Co., Ltd. model is PF8090M62 phenolic resin (62% solid content, 38% acetone solvent) 40g

[0090] Carbonyl iron powder 374g

[0091] 1,2-Dimethylimidazole 0.0625g

[0092] Acetone 40g

[0093] The ratio of the phenolic hydroxyl equivalent of the phenolic resin to the epoxy equivalent of the epoxy resin is 1:1.

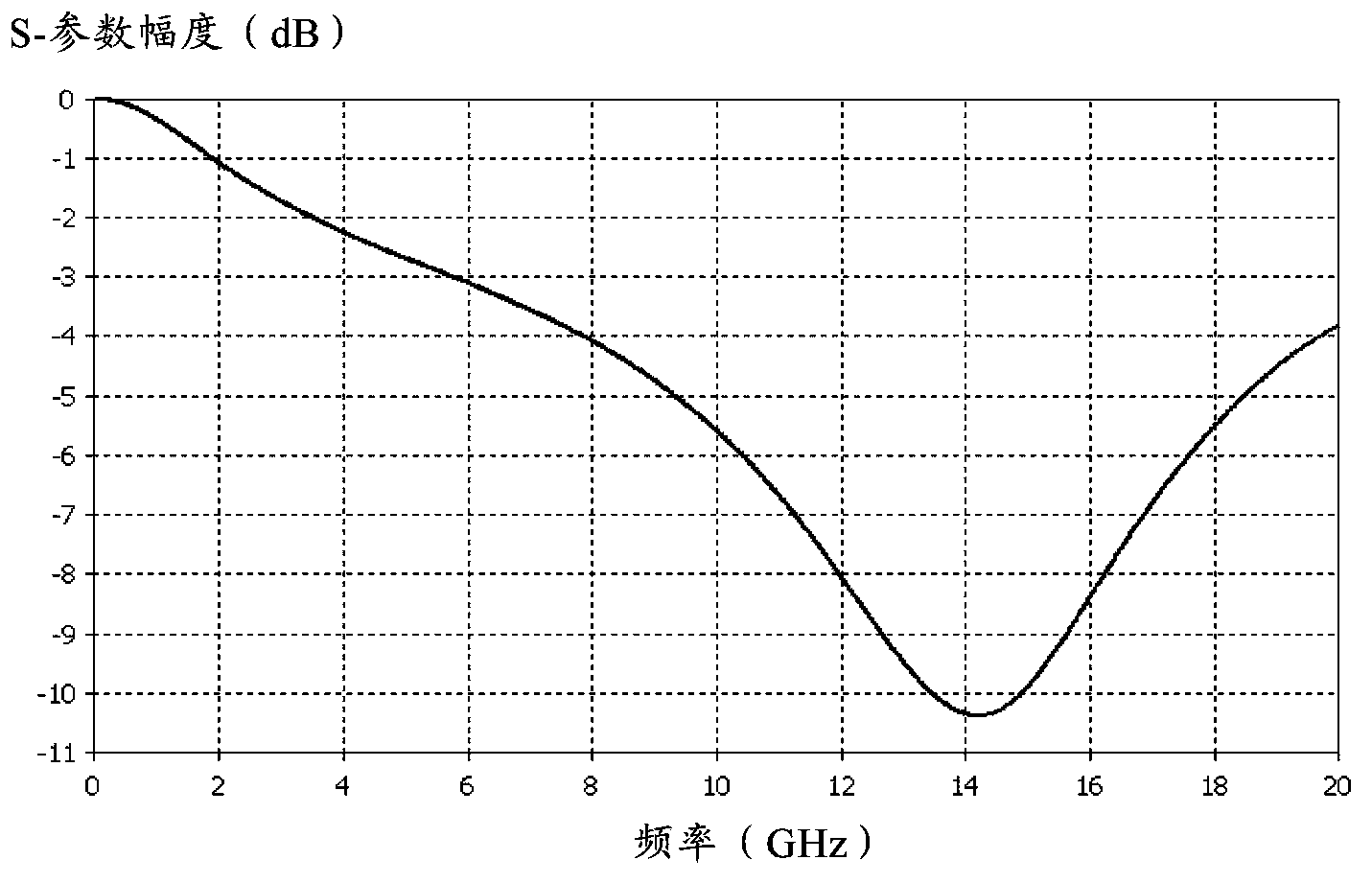

[0094] Preparation method: Stir epoxy resin, phenolic resin, carbonyl iron powder and acetone evenly, add dimethylimidazole and stir to make a glue (for ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com