Mercury removing process based on carrier-induced precipitate crystallization and for mercury-containing waste water from PVC (polyvinyl chloride) production utilizing calcium carbide process

A technology of precipitation crystallization and polyvinyl chloride, applied in the direction of flocculation/sedimentation water/sewage treatment, water pollutants, multi-stage water treatment, etc., can solve the difficult recycling of precipitation products, slow solid-liquid sedimentation and separation, and unfavorable resource recycling and other problems, to achieve the effect of eliminating the need for filters and filtration processes, low investment and treatment costs, and small precipitation reaction devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

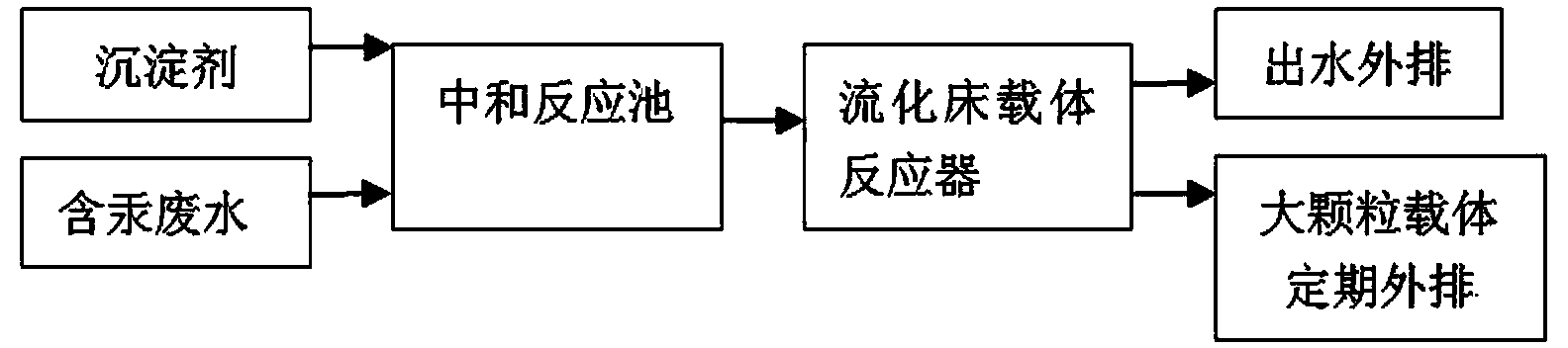

[0015] refer to figure 1 , the specific implementation method adopts the following technical scheme: based on the carrier-induced precipitation and crystallization of mercury removal process for polyvinyl chloride mercury-containing wastewater, the mercury removal process flow is: precipitant and mercury-containing wastewater-neutralization reaction tank-flow Chemicalized bed carrier reactor - the effluent is discharged, and the large particle carrier is discharged regularly.

[0016] The core of the fluidized bed carrier-induced precipitation and crystallization technology is to fill the bottom of the reactor with appropriate crystal-inducing materials, pump water or waste water into the bottom of the reactor to make the crystal-inducing carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com