Apparatus and method for polishing three-dimensional printed plastic/resin pieces

A technology of three-dimensional printing and plastics, which is applied to the equipment for surface polishing of resin parts, in the field of plastics, it can solve the problems of polluting the indoor environment, polishing the internal surface, insufficient gas exchange, etc., and achieve the effect of restoring surface hardness and high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

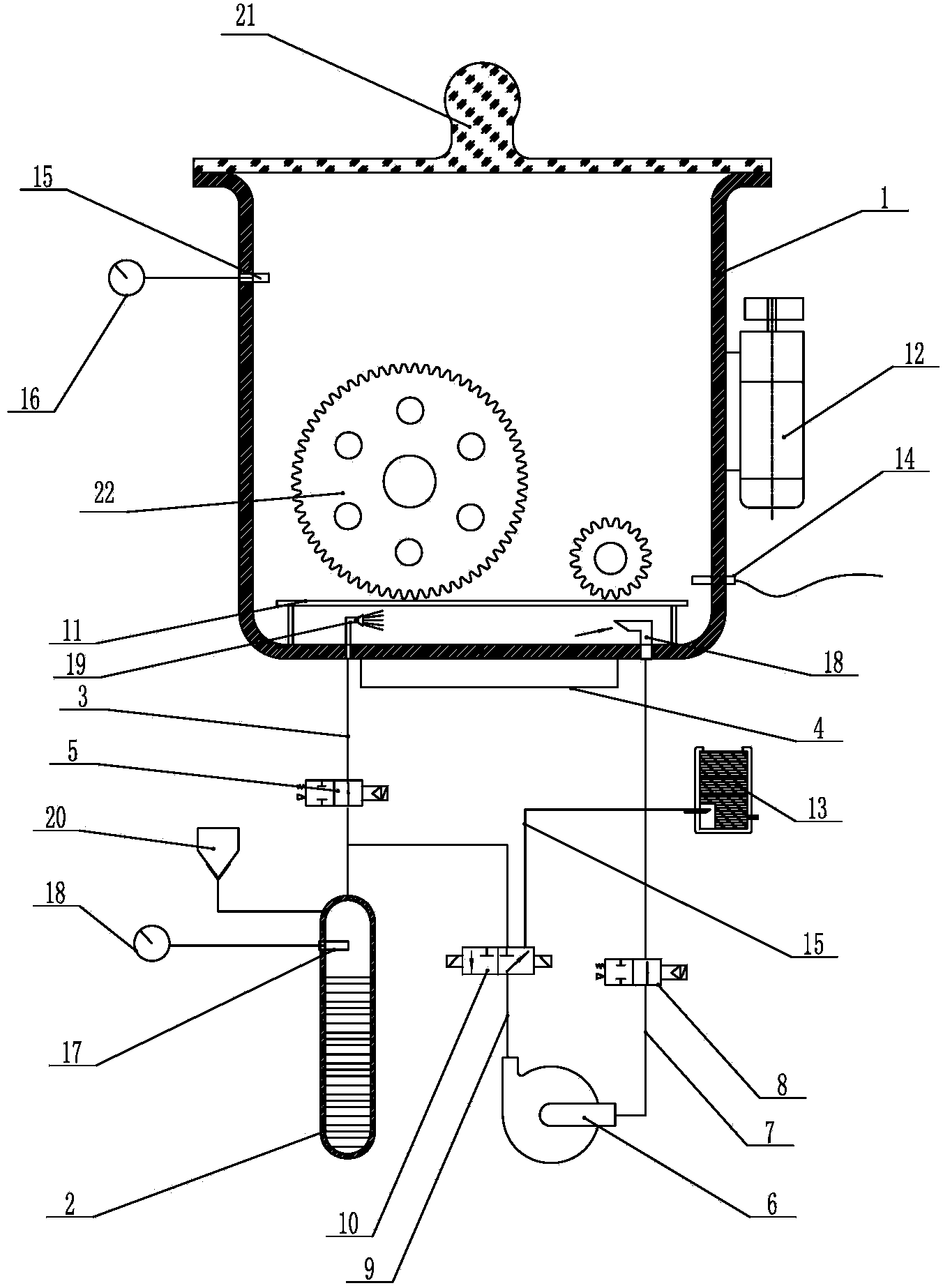

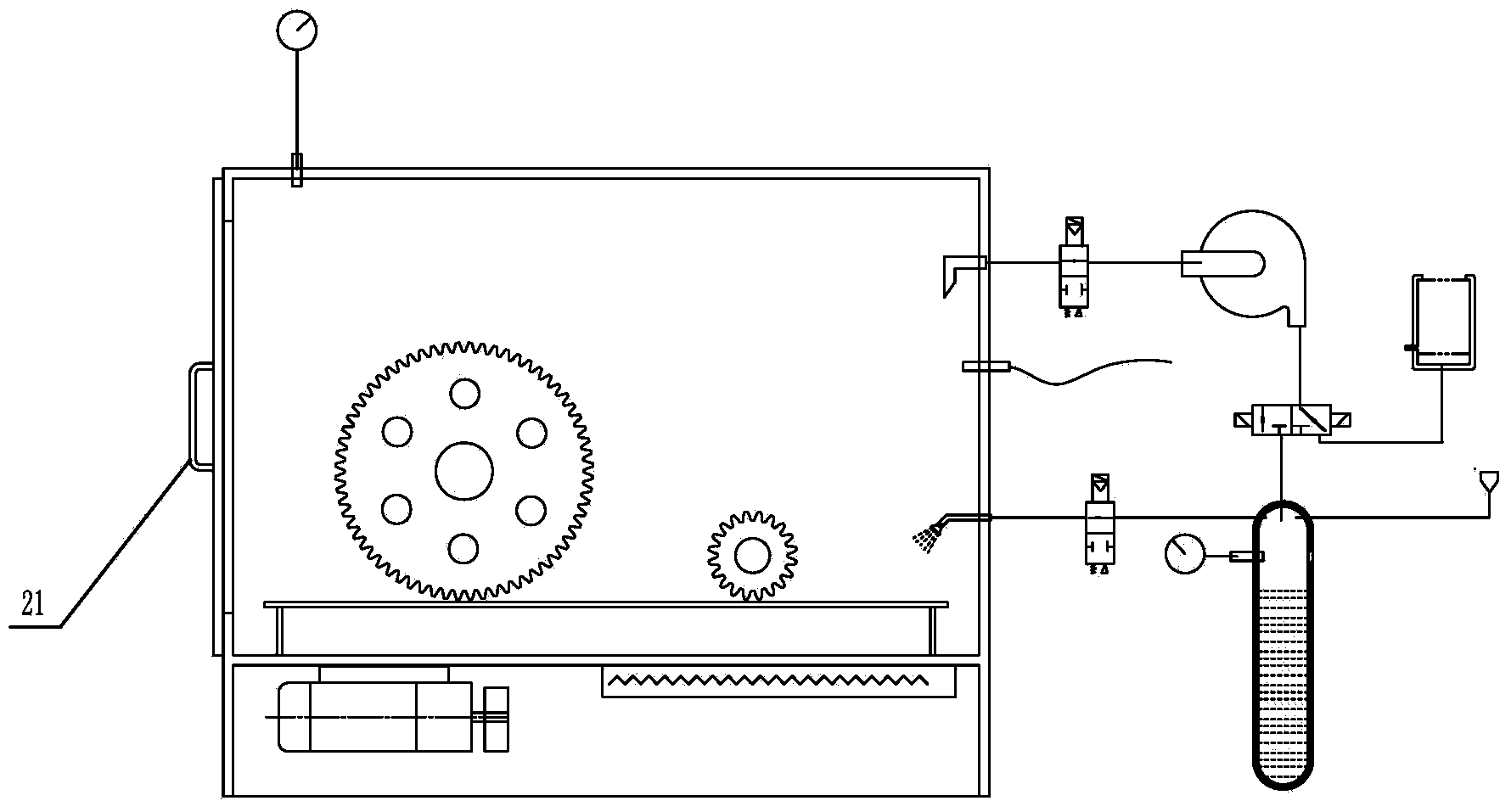

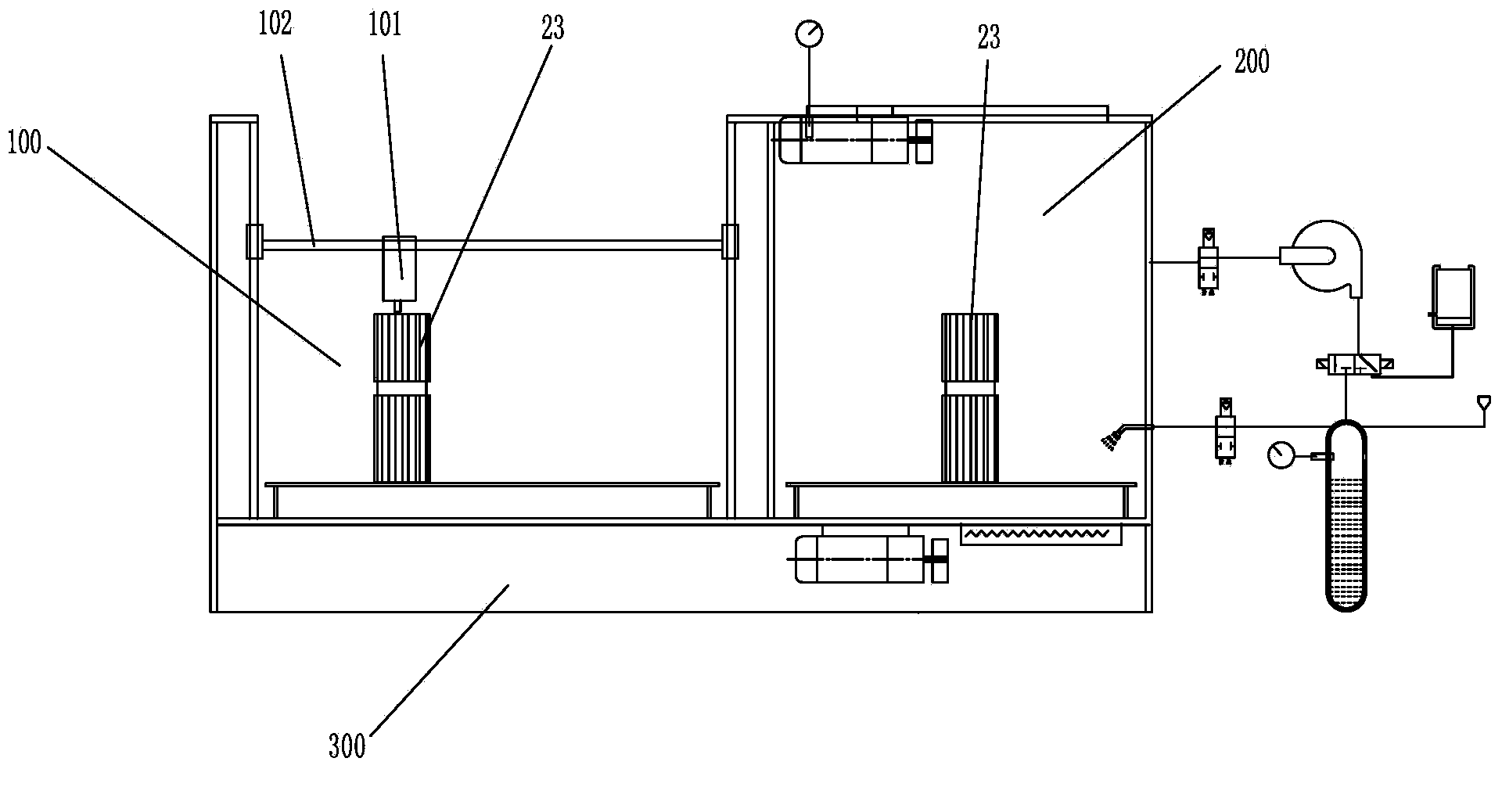

[0042] Such as figure 1 The three-dimensional printing plastic and resin parts polishing equipment shown in , includes a polishing chamber 1 and a solvent storage tank 2 , and the polishing chamber 1 and the solvent storage tank 2 are connected through a liquid inlet pipe 3 . The polishing chamber 1 is an airtight container, and the liquid inlet pipe 3 is provided with a two-position two-way reversing valve one 5 . It also includes a vacuum device, wherein the vacuum device can use a vacuum pressure pump, or a combination of a vacuum pump and a pressure pump, or choose one of the vacuum pressure pump and the pressure pump, and the number used can be selected according to the actual situation. The vacuum device is current technology. The vacuum device in the present embodiment adopts vacuum pump 6, and the air inlet of this vacuum pump 6 is connected with polishing chamber 1 through suction pipe 7, and suction pipe 7 is provided with two-position two-way reversing valve 2 8, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com