how to make thz antenna array

A manufacturing method and technology of antenna arrays, applied in the directions of antenna arrays, antennas, light guides, etc., can solve problems such as alignment difficulties, the advantages of array antennas cannot be fully utilized, and uneven radiation intensity of array units, so as to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

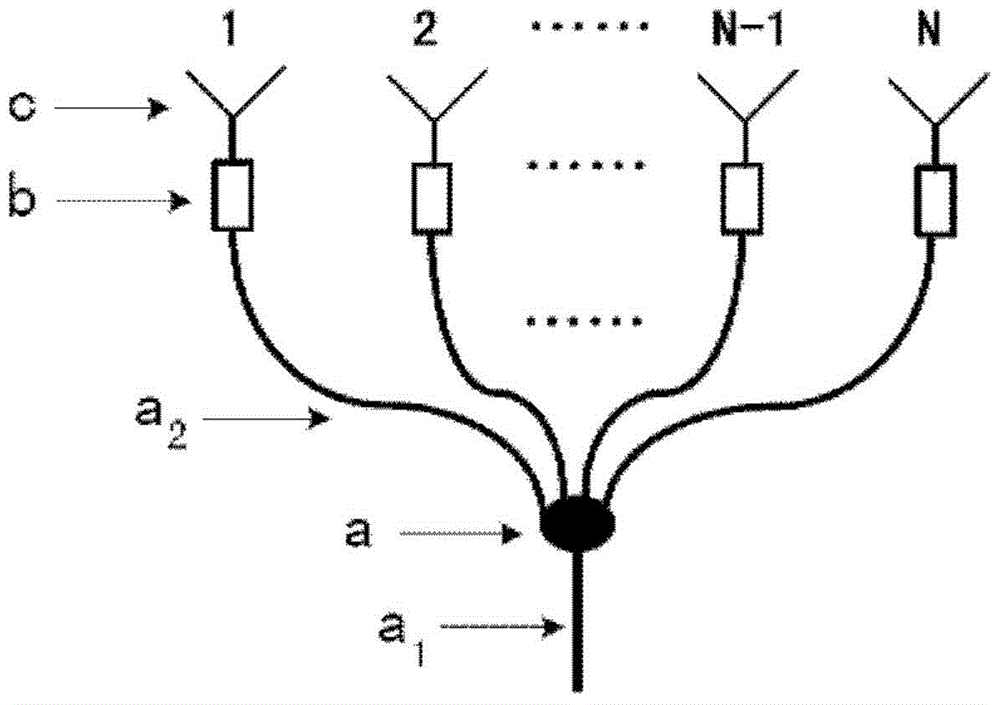

[0029] see figure 1 as shown, figure 1 It is a schematic diagram of a THz antenna array based on an InP-based optical mixer according to an embodiment of the present invention, including an input waveguide a1, a 1×N optical splitter a, N optical mixers b, and connecting N optical mixers b and optical splitters N passive waveguides a2 and N THz antennas c of a.

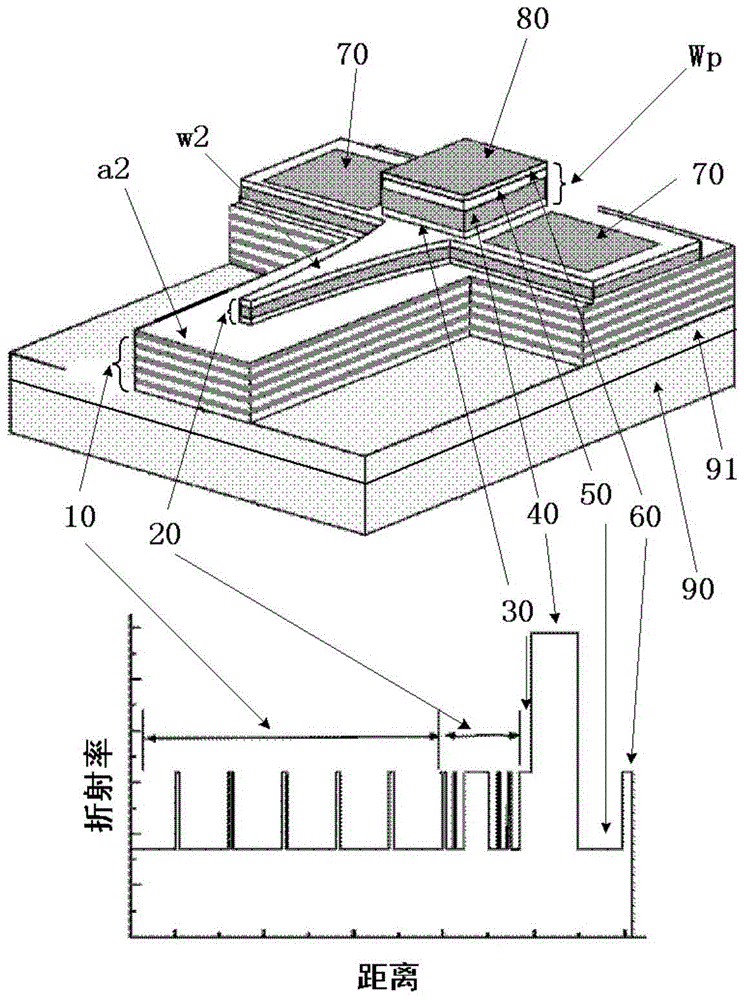

[0030] figure 2 It is a structural diagram of the unit mixer b of the THz antenna array based on the InP-based optical mixer according to the embodiment of the present invention. Fabricate a THz array. On the InP substrate 90, a buffer layer 91 and a passive waveguide layer 10 are successively grown. The passive waveguide layer 10 can be composed of InP layers (low refractive index layers) and InGaAsP layers with multiple cycles (the number of cycles in this embodiment is 5). Layers (high refractive index layers) are alternately composed, and may be composed of InGaAsP material alone. An optical coupling layer 20 ...

Embodiment 2

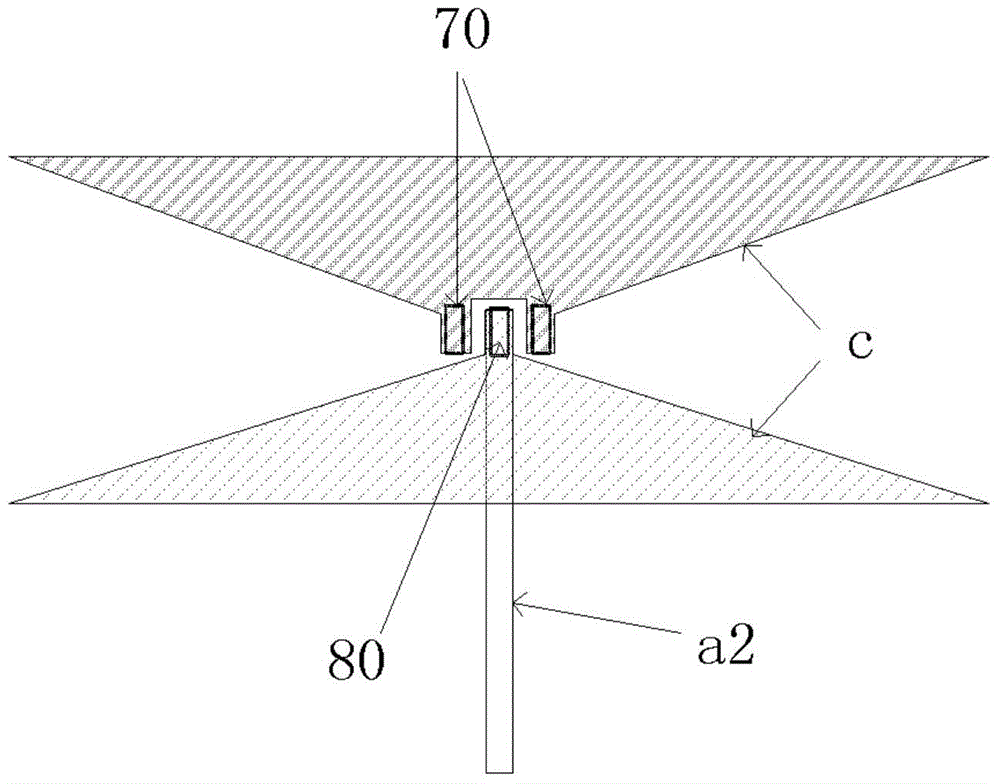

[0038] see Figure 5 , the implementation of the second embodiment is basically the same as that of the first embodiment, and the difference with the first embodiment is that the electrode d is made on the upper part of the passive waveguide a2 of the array, and the effective refractive index of the material of the waveguide layer 10 can be changed by current injection, thereby changing The optical path difference of the pump light between each mixer unit b constitutes a staring THz antenna array.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com