Mesoporous composite oxide catalyst for purifying tail gases and preparation method thereof

A composite oxide and tail gas purification technology, applied in the field of environmental catalytic purification, to achieve the effect of excellent low-temperature catalytic activity and wide reaction window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

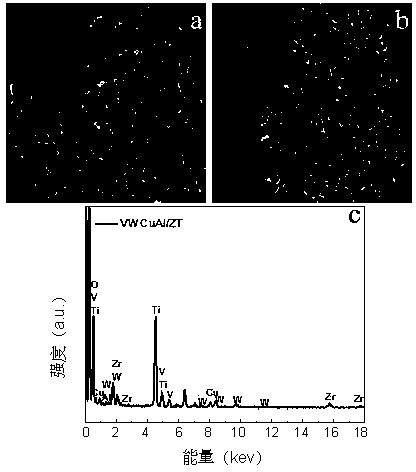

Image

Examples

preparation example Construction

[0037] In addition, the present invention also provides a method for preparing a catalyst for purifying diesel vehicle exhaust, comprising the following steps:

[0038] ① Dissolve 4.5g of Brij-35, 3.7g of P123 and 1g of oxalic acid in 100mL of water, add vanadium salt, tungsten salt, copper salt and aluminum salt calculated according to the weight percentages of V, W, Cu, and Al into the prepared oxalic acid solution. 20-50℃ water bath heating and stirring for 2-6h;

[0039] ② Take 1.2ml of zirconium n-propoxide and 8.8ml of tetrabutyl titanate dropwise into 40ml of ethanol solution, and stir at room temperature for 1-5h;

[0040] ③ Add the solution prepared in step ② dropwise into the solution prepared in step ①, heat in a water bath at 20-50°C and stir for 6-12 hours;

[0041] ④ Transfer the mixture to a hydrothermal kettle, heat it with water at 100-150°C for 24 hours, then wash and filter and dry at 80-120°C;

[0042] ⑤ Place the dried catalyst powder in step ④ in a muff...

Embodiment 1

[0055] ① Dissolve 4.5g of Brij-35, 3.7g of P123 and 1g of oxalic acid in 100mL of water, and dissolve the ammonium metavanadate, ammonium metatungstate, copper sulfate pentahydrate, isopropanol calculated according to the weight percentages of V, W, Cu and Al. Aluminum was added to the prepared oxalic acid solution, heated in a 30°C water bath and stirred for 3h;

[0056] ② Take 1.2ml of zirconium n-propoxide and 8.8ml of tetrabutyl titanate dropwise into 40ml of ethanol solution, and stir at room temperature until a transparent solution is formed;

[0057] ③ Add the solution prepared in step ② dropwise into the solution prepared in step ①, heat in a 30°C water bath and stir for 12 hours until the mixture becomes a uniform emulsion;

[0058] ④ Transfer the mixture into a hydrothermal kettle, heat it with water at 120°C for 24h, then wash with ethanol, filter and dry at 100°C;

[0059] ⑤ Place the dried catalyst powder in step ④ in a muffle furnace, and calcinate at 500 ° C fo...

Embodiment 2

[0062] ① Dissolve 4.5g of Brij-35, 3.7g of P123 and 1g of oxalic acid in 100mL of water, add ammonium metavanadate, ammonium metatungstate and copper nitrate calculated according to the weight percentages of V, W and Cu into the prepared oxalic acid solution. Heated in a water bath at 30°C and stirred for 3h;

[0063] ② Take 1.2ml of zirconium n-propoxide and 8.8ml of tetrabutyl titanate dropwise into 40ml of ethanol solution, and stir at room temperature until a transparent solution is formed;

[0064] ③ Add the solution prepared in step ② dropwise into the solution prepared in step ①, heat in a 30°C water bath and stir for 12 hours until the mixture becomes a uniform emulsion;

[0065] ④ Transfer the mixture into a hydrothermal kettle, heat it with water at 120°C for 24h, then wash with ethanol, filter and dry at 100°C;

[0066] ⑤ Place the dried catalyst powder in step ④ in a muffle furnace, and calcinate at 500 ° C for 4 h to obtain V 2 O 5 -WO 3 -CuO x / ZrO 2 -TiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com