Method for preparing balloon dilatation catheter medicinal coating for treatment

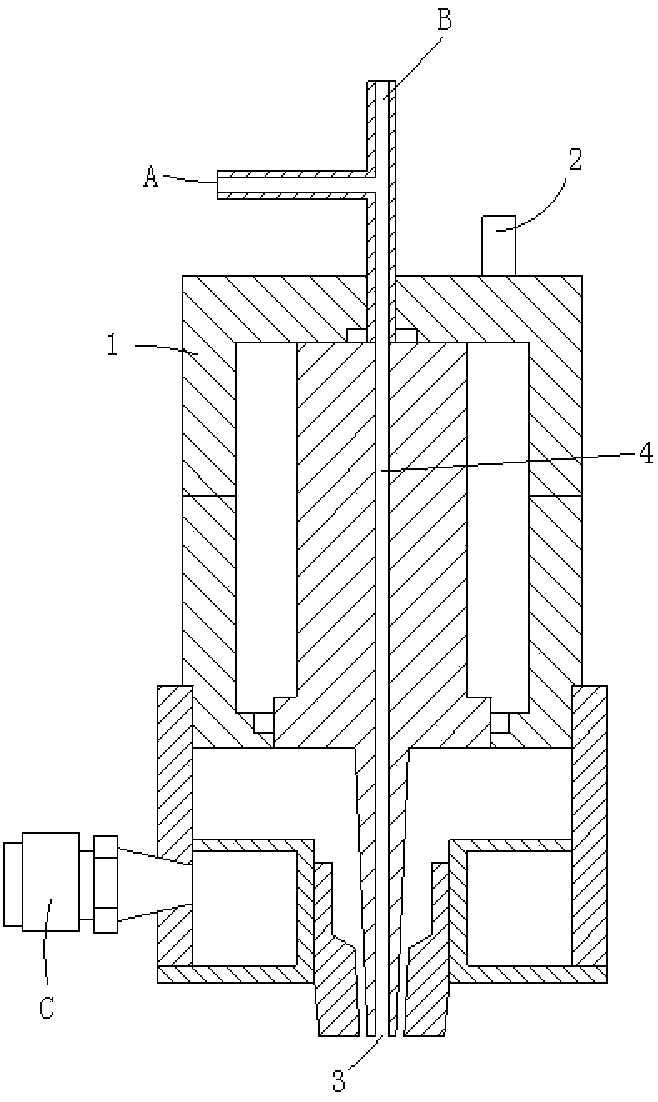

A technology for dilating catheters and drug coatings, applied in coatings, medical science, surgery, etc., can solve problems such as high material consumption, narrow stents, large airflow, and the environment, and achieve uniform drug coating, long-lasting drug effects, crystal Effects with controllable granularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

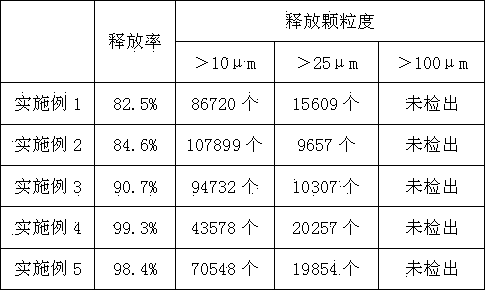

Embodiment 1

[0044] Embodiment 1: Preparation method of paclitaxel drug-coated balloon:

[0045] Step 1, paclitaxel solution: Weigh about 0.15g of paclitaxel and add it to a 25ml glass bottle; add 20ml of acetonitrile / acetone 1:1 (v / v) mixed solution into the glass bottle, shake until the paclitaxel is completely dissolved.

[0046] Step 2, paclitaxel incompatible solution: 0.18g of PVP was dissolved in 20ml of 75% medical alcohol.

[0047] Step 3, spraying parameters: pressurize a 2.0*20mm balloon until it is fully stretched and place it under the ultrasonic nozzle, the ultrasonic frequency is 25kHz, the ultrasonic power is set to 1w, the flow rate of paclitaxel solution is 0.1ml / min, paclitaxel does not The flow rate of the compatible solution is 0.05ml / min, the rotation speed of the balloon is 3r / s, the spraying stroke is 20mm, the spraying time is 0.5min, and the carrier gas pressure is 1psi; after spraying, take out the balloon.

[0048] In step 4, the balloon is dried for 30 minutes...

Embodiment 2

[0050] Embodiment 2: Preparation method of paclitaxel drug-coated balloon:

[0051] Step 1, paclitaxel solution: Weigh about 0.13g of paclitaxel and add it to a 15ml glass bottle; add 10ml of a mixed solution of ethanol / n-hexane 3:1 (v / v) into the glass bottle and shake until the paclitaxel is completely dissolved.

[0052] Step 2, paclitaxel-incompatible solution: an aqueous solution with a PEG content of 20 mg / ml.

[0053] Step 3, spraying parameters: pressurize a 3.0*15mm balloon until it is fully stretched and place it under the ultrasonic nozzle, the ultrasonic frequency is 60kHz, the ultrasonic power is set to 0.8w, the flow rate of paclitaxel solution is 0.15ml / min, paclitaxel The incompatible solution flow rate is 0.1ml / min, the balloon rotation speed is 3r / s, the spraying stroke is 15mm, the spraying time is 1.1min, and the carrier gas pressure is 1psi; after the spraying, take out the balloon.

[0054] In step 4, the balloon is dried for 60 minutes at a temperature ...

Embodiment 3

[0056] Embodiment 3: Preparation method of paclitaxel drug-coated balloon:

[0057] Step 1, paclitaxel solution: Weigh about 0.13g of paclitaxel and add it to a 15ml glass bottle; add 10ml of methanol / isopropanol 2:1 (v / v) mixed solution into the glass bottle, shake until the paclitaxel is completely dissolved.

[0058] Step 2, paclitaxel-incompatible solution: 50% water / acetone solution with a PVA content of 10 mg / ml.

[0059] Step 3, spraying parameters: pressurize a 6.0*40mm balloon until it is fully stretched and place it under the ultrasonic nozzle, the ultrasonic frequency is 50kHz, the ultrasonic power is set to 4w, the flow rate of paclitaxel solution is 0.2ml / min, paclitaxel does not The flow rate of the compatible solution is 0.2ml / min, the rotation speed of the balloon is 5r / s, the spraying stroke is 40mm, the spraying time is 3min, and the carrier gas pressure is 1psi; after spraying, take out the balloon.

[0060] In step 4, the balloon is dried for 10 minutes at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com