Production process of instant kelp and Spanish mackerel foods

A production process, the technology of kombu mackerel, is applied in the field of production technology of instant kombu mackerel food, which can solve the problems of large loss of nutrients, contradiction between fast food and nutrition and health care, and achieve less loss of nutrients, high production efficiency, The effect of increasing profit margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

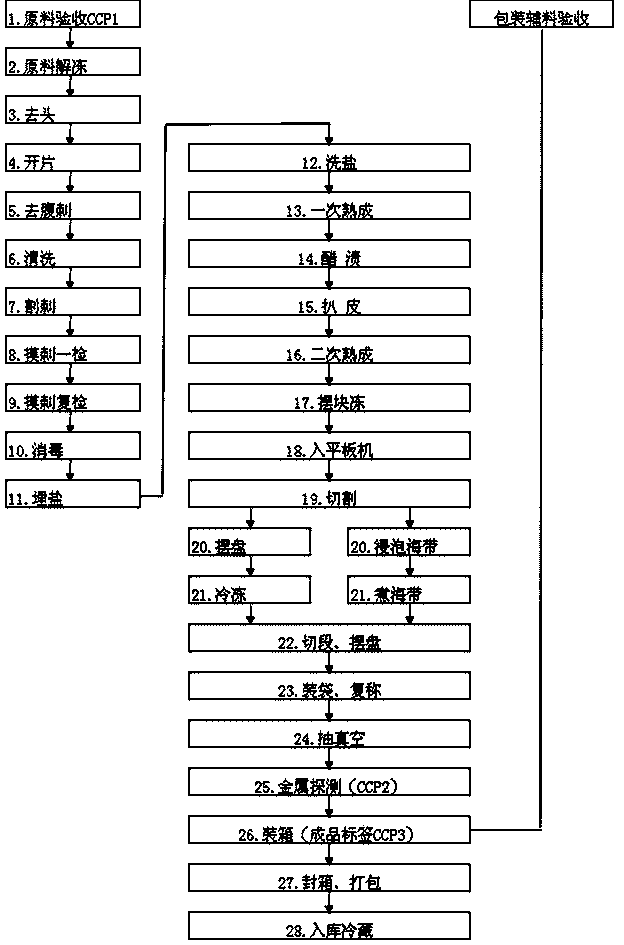

[0046] A kind of production technology of instant kombu mackerel food as shown in Figure 1, it comprises the following steps:

[0047] (1) Spanish mackerel processing:

[0048] (1) Acceptance of raw materials: the surface of the fish body is shiny, the freezing hardness is good, the fish meat at the cut surface is white, no yellowing, no air-drying, no corruption, the smell is normal fish smell, no peculiar smell, and the packaging is intact without contamination. Body center temperature below -18°C;

[0049] (2) Raw material thawing: After extracting the raw material from the large warehouse, put it on the thawing rack and arrange it sequentially, and control the product temperature below -7°C;

[0050] (3) Remove the head: take the fish gill cover as a reference object, cut off the head 1cm away from the fish gill cover;

[0051] (4) Slicing: Put the Spanish mackerel on the wooden board, pull it down with the special knife for mackerel with the tail facing outwards, and open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com