Anti-electromagnetic interference high-elasticity spiral cable connecting line

An anti-electromagnetic interference, spiral cable technology, applied in the direction of connection, insulated cable, cable/conductor manufacturing, etc., can solve the problems of reducing the working life, the motor is easily damaged, etc., to achieve high working efficiency, increase working range, and work coverage large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

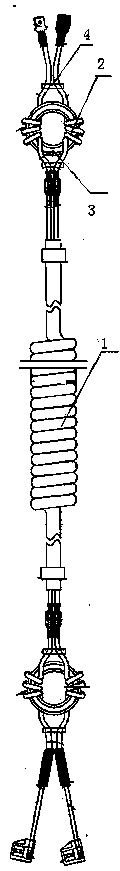

Image

Examples

example 1

[0039] An anti-electromagnetic interference high-elasticity spiral cable connection line, wherein the production steps of the connection line are as follows:

[0040] 1. The copper wire conductor is used for bundle twisting to make the inner core wire of the cable;

[0041] 2、 Prepare the cable material, the composition of the cable material is as follows by weight fraction:

[0042] Thermoplastic polyurethane elastomer 100 parts

[0043] EPDM rubber 50 parts

[0044] PVC resin 50 parts

[0045] Calcium carbonate 15 parts

[0047] Calcium zinc composite stabilizer 5 parts

[0048] High temperature plasticizer TOTM 6 parts

[0049] 8 parts antimony trioxide

[0050] Antioxidant 5 parts

[0051] 3 parts polyimide;

[0052] 3. Preparation of cables

[0053] (1) After fully mixing the components of the cable material, carry out drying treatment, the drying temperature is: 140 °C; the time is: 4 hours;

[0054] (2) Coat the cable material pr...

example 2

[0059] An anti-electromagnetic interference high-elasticity spiral cable connection line, wherein the production steps of the connection line are as follows:

[0060] 1. The copper wire conductor is used for bundle twisting to make the inner core wire of the cable;

[0061] 2、 Prepare the cable material, the composition of the cable material is as follows by weight fraction:

[0062] Thermoplastic polyurethane elastomer 90 parts

[0063] EPDM rubber 45 parts

[0064] PVC resin 45 parts

[0065] Calcium carbonate 12 parts

[0067] Calcium zinc composite stabilizer 4 parts

[0068] High temperature plasticizer TOTM 4 parts

[0069] 12 parts of antimony trioxide

[0070] Antioxidant 6 parts

[0071] 5 parts of polyimide;

[0072] 3. Preparation of cables

[0073] (1) After fully mixing the components of the cable material, carry out drying treatment, the drying temperature is: 150 ° C; the time is: 4.5 hours;

[0074] (2) Coat the cable mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com