Epitaxial production method capable of effectively improving P-GaN hole injection layer quality

A technology of hole injection layer and production method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of device luminous performance degradation, low hole concentration, and difficult activation, so as to improve antistatic ability and luminous brightness , Improve the effect of activation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

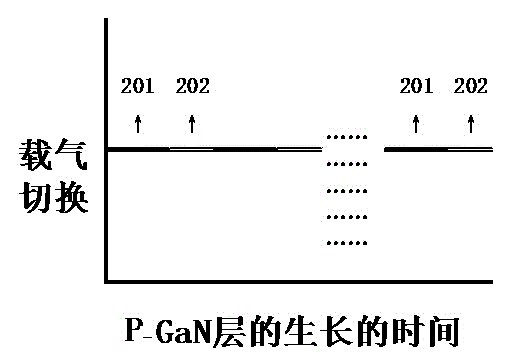

[0024] like figure 1 As shown, the present invention discloses an epitaxial production method that can effectively improve the quality of the p-GaN hole injection layer, using MOCVD technology, using NH3, TMGa or TEGa, TMIn, TMAl as N source, Ga source, In source and Al source, using Cp 2 Mg and SiH 4 As the dopant source of Mg and Si, similar to the existing method, the method comprises the following steps:

[0025] First, grow a GaN low-temperature buffer layer with a thickness of 25nm on the substrate, with H 2 As a carrier gas, the growth temperature is 450-650°C and the pressure is 50-1000mbar.

[0026] Then, the temperature is raised to grow an unintentionally doped GaN layer with a thickness of 1.5 μm on the GaN low-temperature buffer layer at a growth temperature of 850-1200° C. and a pressure of 50-1000 mbar.

[0027] Next, an n-GaN electron injection layer with a thickness of 2.5 μm is grown on the unintentionally doped GaN layer. Using SiH 4 Doping, the dopin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com