Hydraulic buffer performance testing method based on computer

A technology of hydraulic buffers and testing methods, which is applied in the testing of mechanical components, testing of machine/structural components, impact testing, etc. It can solve the problems of low precision, low degree of automation, low efficiency, etc., to improve accuracy, Easy operation, accurate control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

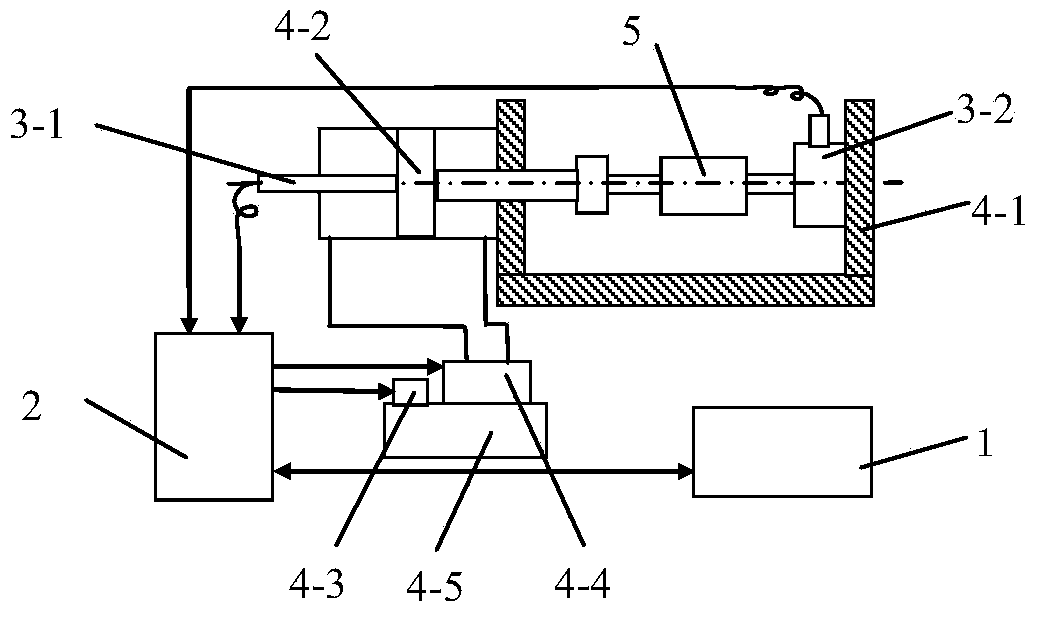

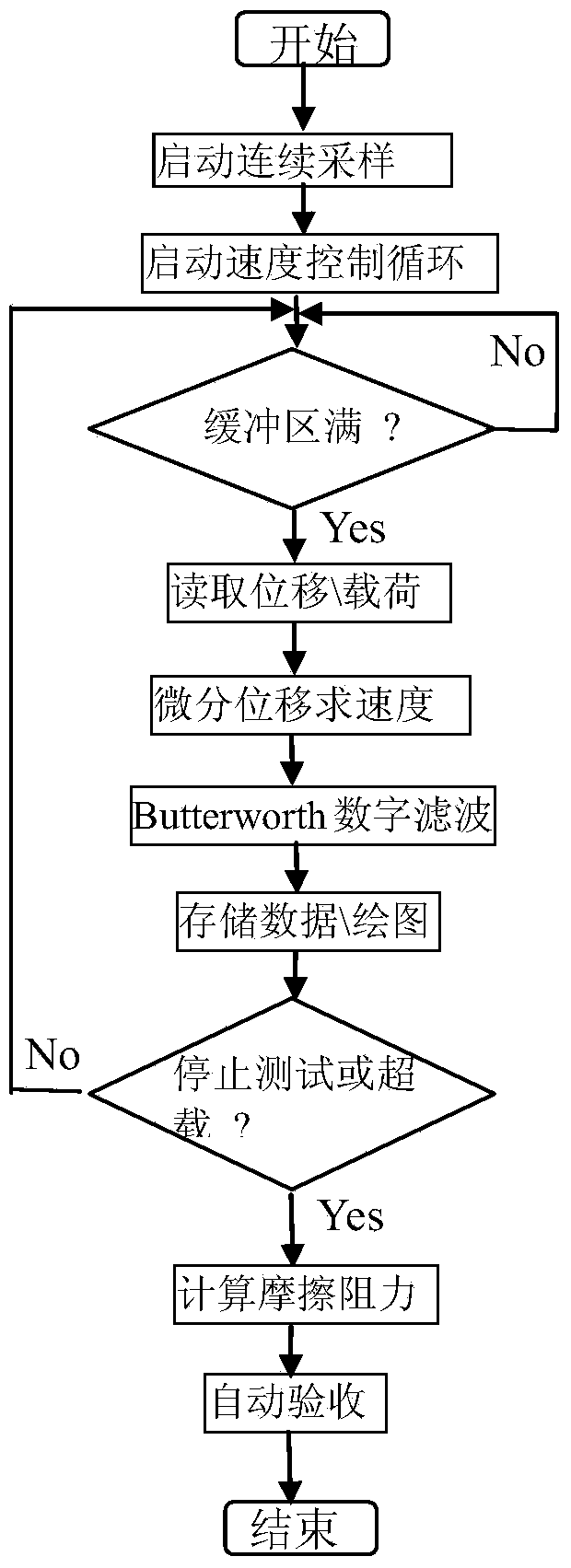

[0042] Such as Figure 1-Figure 4 , a computer-based hydraulic shock absorber performance test method,

[0043] To test the performance of the buffer, it is first necessary to connect the computer 1 to the data acquisition controller 2 as shown in Figure 1, where the data acquisition controller 2 is composed of a multi-function data acquisition card NI PCI-6229 and a terminal box containing a low-pass filter circuit . Connect the voltage output of the LVDT displacement sensor 3-1 and the spoke type tension and compression load sensor 3-2 with the analog input channel in the terminal box. The analog output channels in the terminal box are respectively connected to the input ends of the power amplifiers of the proportional relief valve 4-3 and the proportional reversing valve 4-4. Install the product to be tested 5 between the drive cylinder 4-2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com