Enameled wire polyimide insulating layer nondestructive depainting powder and depainting method

A technology of covering polyimide and insulating layer is applied in the field of non-destructive paint stripping of enameled wires, which can solve the problems of surface damage, broken or left broken wires, uneven thickness of wire ends, etc. Easy to clean and remove with a shiny new finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

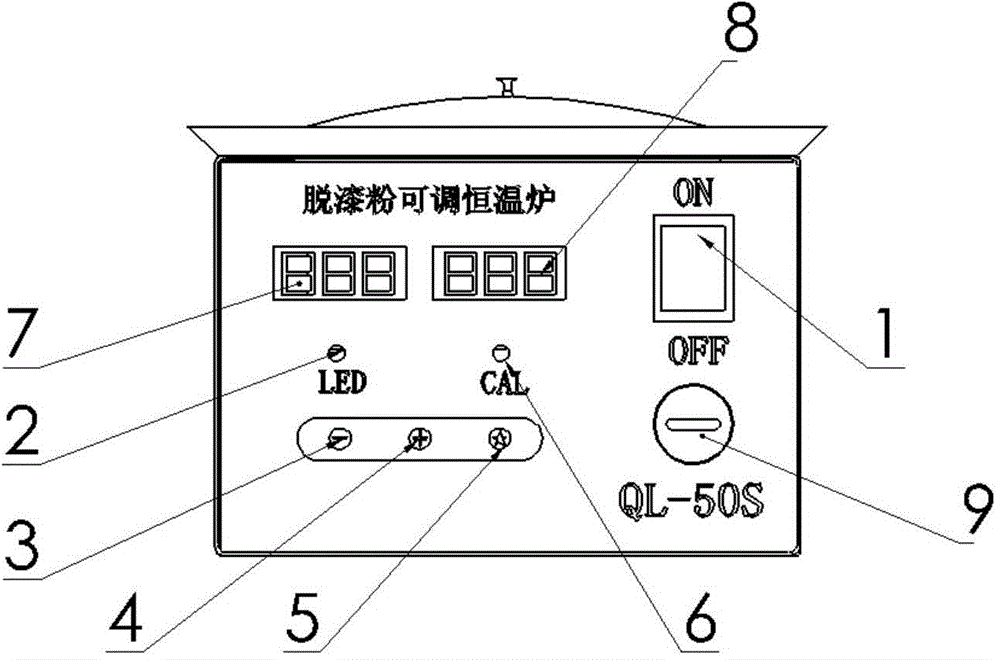

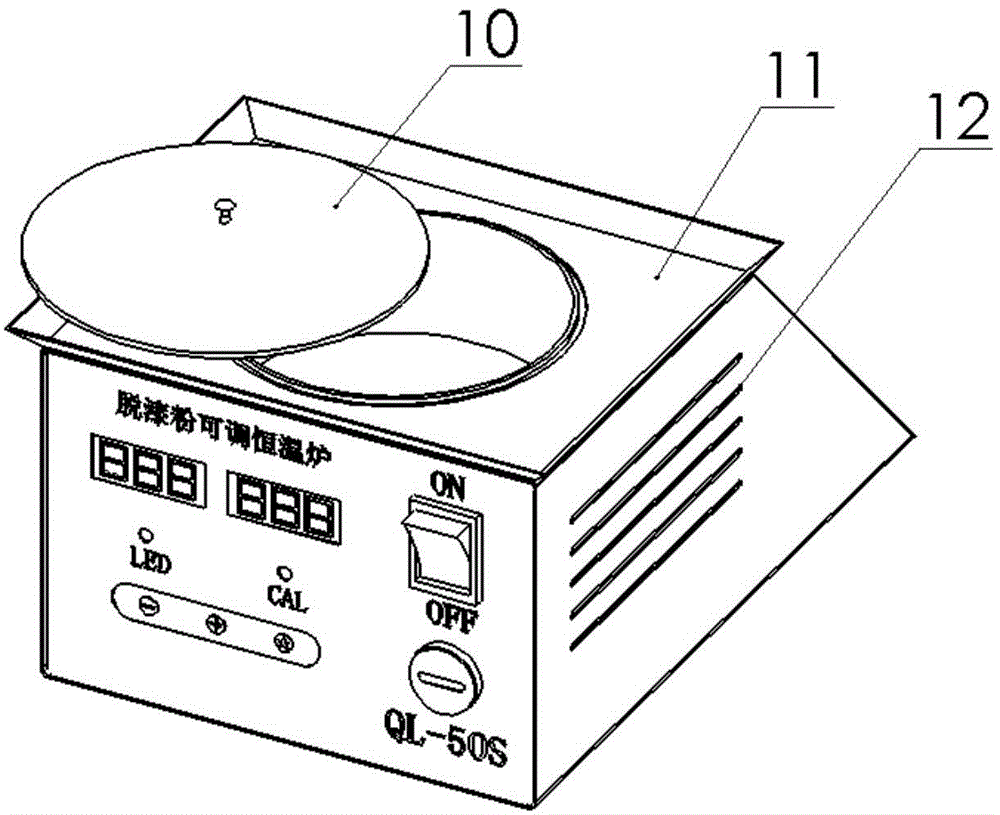

[0020] combined with figure 1 , 2 An embodiment of the present invention is described.

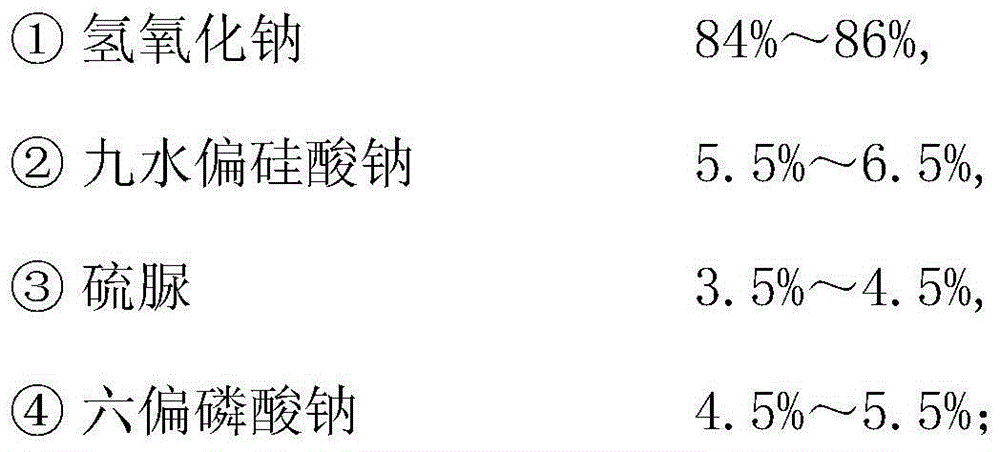

[0021] A kind of non-destructive paint stripping powder for the polyimide insulating layer of enameled wire, is made of the raw material of following weight ratio: sodium hydroxide (NaOH) 85%, sodium metasilicate nonahydrate (NaOH) 2 SiO 3 9H 2 O) 6%, thiourea (CH 4 N 2 S) 4%, sodium hexametaphosphate (NaPO 3 ) 6 5%;

[0022] The preparation method is as follows: take the above four substances respectively, and successively grind them into 20-30 mesh powders in a grinding bowl, fully mix them evenly in a dry environment at room temperature, and store them in airtight condition.

[0023] A non-destructive paint stripping method for an enameled wire polyimide insulating layer, comprising the steps of:

[0024] Step 1: Add the prepared paint stripping powder into the temperature-adjustable paint stripping furnace, and the amount of paint stripping powder added is 3 / 4 of the heating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com