Electroplated metal antiblushing agent and preparation method and using method thereof

A technology for electroplating metal and anti-discoloration agent, applied in the direction of metal material coating process, etc., can solve the problems of affecting the metal protection effect, failing to report the anti-discoloring agent, and decreasing the stability of the solution, and achieves low production cost, good protection effect, The effect of low consumption of film-forming substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

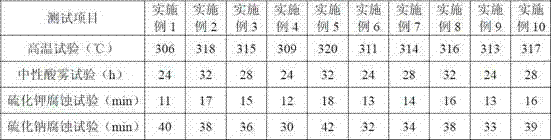

Examples

Embodiment 1

[0044] An anti-tarnish agent for electroplating metal and a preparation method thereof, comprising the steps of: adding 1 / 2L of deionized water to a container, and adding 1 g of potassium silicate according to the proportion while stirring, and stirring until completely dissolved; Under the state, add 0.1 g of potassium fluoride at a uniform speed according to the proportion until it is completely dissolved, and continue stirring for 5 minutes; under the state of stirring, add 10 g of potassium methyl silicate at a constant speed according to the proportion, and continue stirring for 5 minutes after completion; add deionized water to 1L and stir evenly to prepare the electroplating metal anti-tarnish agent.

[0045] A method for using an anti-tarnish agent for electroplated metal, comprising the following steps: removing oil stains, dust and rust on the surface of the electroplated metal; soaking the electroplated metal with the anti-tarnish agent for electroplated metal, the t...

Embodiment 2

[0047] An anti-tarnishing agent for electroplating metal and a preparation method thereof, comprising the steps of: adding 2 / 3L of deionized water to a container, and adding 15 g of potassium silicate according to the proportion while stirring, and stirring until completely dissolved; Under the state, add 2 g of potassium bifluoride at a uniform speed according to the proportion until it is completely dissolved, and continue stirring for 6 minutes; under the state of stirring, add 8 g of potassium trimethylsilicate at a constant speed according to the proportion, and continue stirring for 6 minutes after completion; add deionized water to 1L and stir evenly to prepare the electroplating metal anti-tarnish agent.

[0048] A method for using an anti-tarnish agent for electroplated metal, comprising the following steps: removing oil stains, dust and rust on the surface of the electroplated metal; spraying the electroplated metal with the anti-tarnish agent for electroplated metal,...

Embodiment 3

[0050] An anti-tarnish agent for electroplating metal and a preparation method thereof, comprising the steps of: adding 1 / 2L deionized water to a container, and adding 30 g of sodium silicate according to the proportion while stirring, and stirring until completely dissolved; Under the state, add 3g of sodium fluoride at a uniform speed according to the proportion until it is completely dissolved, and continue stirring for 7 minutes; under the state of stirring, add 7g of ethyl sodium silicate at a constant speed according to the proportion, and continue stirring for 7 minutes after completion; add deionized water to 1L, Stir evenly to prepare the anti-tarnish agent for electroplating metal.

[0051] A method for using an anti-tarnish agent for electroplated metal, comprising the following steps: removing oil stains, dust and rust on the surface of the electroplated metal; soaking the electroplated metal with the anti-tarnish agent for electroplated metal, the temperature used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com