Composite solid-state electrolyte membrane, preparation method and solid-state lithium battery

A solid electrolyte membrane, solid electrolyte technology, applied in solid electrolytes, non-aqueous electrolytes, secondary batteries, etc., to improve cycle stability, good interface compatibility, and improve capacity and rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] (1) Preparation of positive pole piece

[0042]Step 1: Add the binder, conductive agent, and positive electrode active material to the NMP solvent in turn for dispersion and stirring to obtain the positive electrode slurry; Step 2: Use a coating machine to coat the positive electrode slurry on the aluminum foil. The drying temperature is 120°C, and the coiled electrode sheet is dried in a vacuum oven at 100°C for 24 hours, and the dried electrode sheet is rolled and punched to obtain the positive electrode sheet;

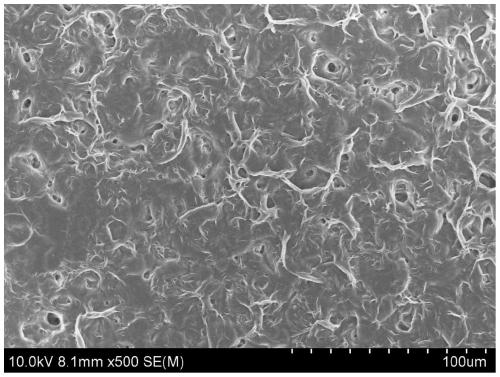

[0043] (2) Preparation of composite solid electrolyte membrane

[0044] Step 1: Mix organic polymer A, lithium salt, nano-inorganic solid electrolyte and solvent to obtain organic-inorganic composite slurry A, and the solid content of the slurry is 2-8%; Step 2: Mix organic polymer B, lithium salt, nano Inorganic solid electrolyte and solvent are mixed to obtain organic-inorganic composite slurry B, and the solid content of the slurry is 2-8%; Step 3: Coatin...

Embodiment 1

[0049] (1) Preparation of positive pole piece

[0050] Step 1: binder PVDF, conductive agent SuperP, positive electrode active material LiFePO 4 Add it to NMP solvent in order of mass ratio 10:10:80 for dispersion and stirring to obtain positive electrode slurry; Step 2: Coat the positive electrode slurry on the aluminum foil with a coating machine, and the drying temperature of the coating machine is 120°C , the pole piece after winding was dried in a vacuum oven at 100°C for 24 hours, and the dried electrode piece was rolled and punched to obtain the positive pole piece;

[0051] (2) Preparation of composite solid electrolyte membrane

[0052] Step 1: Mix 0.3g polyvinylidene fluoride PVDF, 0.1gLiTFSI, 0.05gLi 7 La 3 Zr 2 o 12 Mix with 10gDMF to obtain organic-inorganic composite slurry A; Step 2: 0.3g polyethylene oxide PEO, 0.1g LiTFSI, 0.05g Li 7 La 3 Zr 2 o 12 Mix with 10g of acetonitrile to obtain organic-inorganic composite slurry B; step 3: apply organic-inorg...

Embodiment 2

[0058] (1) Preparation of positive pole piece

[0059] Step 1: binder PVDF, conductive agent SuperP, positive electrode active material LiNi 0.5 co 0.2 mn 0.3 o 2 Add it to NMP solvent in order of mass ratio 10:10:80 for dispersion and stirring to obtain positive electrode slurry; Step 2: Coat the positive electrode slurry on the aluminum foil with a coating machine, and the drying temperature of the coating machine is 120°C , the pole piece after winding was dried in a vacuum oven at 100°C for 24 hours, and the dried electrode piece was rolled and punched to obtain the positive pole piece;

[0060] (2) Preparation of composite solid electrolyte membrane

[0061] Step 1: Mix 0.3g polyvinylidene fluoride PVDF, 0.1gLiTFSI, 0.05gLi 7 La 3 Zr 2 o 12 Mix with 10gDMF to obtain organic-inorganic composite slurry A; Step 2: 0.3g polyethylene oxide PEO, 0.1g LiTFSI, 0.05g Li 7 La 3 Zr 2 o 12 Mix with 10g of acetonitrile to obtain organic-inorganic composite slurry B; step 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com