Reaction type nylon flame retardant and preparation method

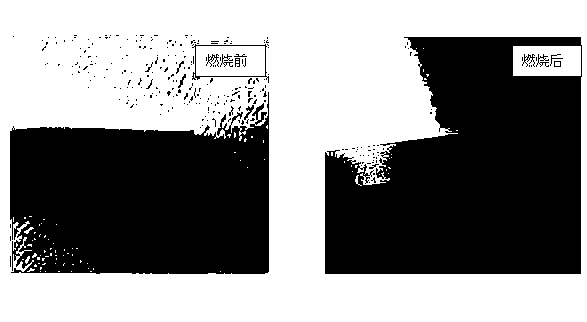

A flame retardant and reactive technology, applied in the field of flame retardants, can solve the problems of a large amount of harmful smoke and corrosive gas, other performance degradation of composite materials, and color deterioration of composite materials, and achieve high practical value and high phosphorus content , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

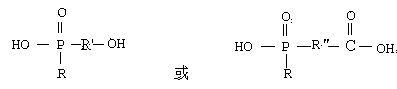

Method used

Image

Examples

Embodiment 1

[0054] Take 1.8Kg of ethylene glycol and 2.5Kg of hydroxymethylphenyl hypophosphorous acid into the reaction kettle, raise the temperature to 80°C, blow in nitrogen, esterify at 150°C for 3~5h, then at 170°C, -0.02~-0.096MPa Reaction under reduced pressure for 3~6 hours, the esterification rate is above 99%, and when no distillate is produced, stop the reaction, lower the temperature to 120°C, and discharge the material to obtain a flame-retardant esterification liquid, which is cooled for later use.

[0055] Take 2.2Kg of flame-retardant esterification liquid and 0.6Kg of malonic acid into the reaction kettle, raise the temperature to 80°C, blow in nitrogen, stir well, and esterify at 150°C for 3h~5h, then at 170°C, -0.02~ Reaction under reduced pressure at -0.096MPa for 3~6h. When no distillate is produced, stop the reaction, lower the temperature to 120°C, and discharge the material to obtain a reactive nylon flame retardant.

Embodiment 2

[0057] Take 3.1Kg of ethylene glycol and 4.8Kg of hydroxyethylphenyl hypophosphorous acid into the reaction kettle, raise the temperature to 80°C, blow in nitrogen, esterify at 80°C for 3~5h, then at 150°C, -0.02~-0.096MPa Reaction under reduced pressure for 3~6 hours, the esterification rate is above 99%, and when no fraction is produced, stop the reaction, lower the temperature to 100°C, and discharge the material to obtain a flame-retardant esterification liquid, which is cooled for later use.

[0058] Take 6.2Kg of flame retardant esterification liquid and 1.6Kg of malonic acid into the reaction kettle, raise the temperature to 80°C, blow in nitrogen, stir well, esterify at 80~150°C for 3~5h, then at 150°C, - Reaction under reduced pressure at 0.02~-0.096MPa for 3~6h, when no distillate is produced, stop the reaction, lower the temperature to 100°C, and discharge the material to obtain a reactive nylon flame retardant.

Embodiment 3

[0060] Take 1.8Kg of ethylene glycol and 3.1Kg of 2-carboxyethylphenyl hypophosphorous acid and add them into the reaction kettle, raise the temperature to 80°C, feed in nitrogen, stir well, and gradually heat up after the 2-carboxyethylphenylphosphorous acid is completely dissolved. Esterify at 140°C for 3~5h, then react under reduced pressure at 160°C and -0.02~-0.096MPa for 3~6h, the esterification rate is above 99%, stop the reaction when no fraction is produced, and lower the temperature to 110°C , discharging, to obtain a flame retardant esterified liquid, cooled for subsequent use.

[0061] Take 3.8Kg of flame retardant esterification solution and 1.5Kg of adipic acid into the reaction kettle, raise the temperature to 80°C, blow in nitrogen, stir well, and esterify at 140°C for 3~5h, then at 160°C, -0.02~ Reaction under reduced pressure at -0.096MPa for 3-6h. When no distillate is produced, stop the reaction, lower the temperature to 110°C, and discharge the material to...

PUM

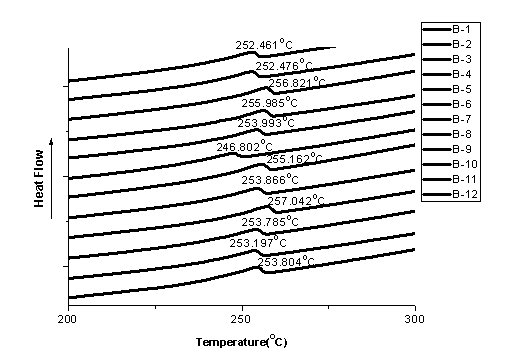

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com