Formula used for synthesizing NDI-based polyurethane microcellular elastomer

A technology of microporous elastomer and polyurethane, which is applied in the formulation field of synthetic NDI-based polyurethane microporous elastomer, can solve the problems of reducing the product, reducing the hardness of the finished product, and reducing the temperature resistance, so as to expand the application range, improve the reaction speed, Reduces the effect of endogenous heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1000g of poly(butylene adipate) with an average relative molecular weight of 2000 and 286g of NDI were reacted at 130°C for 1h to obtain a prepolymer with -NCO%=5.64%; the chain extender component was 20g of 1,4- A mixture of butanediol and 51g of 4,4'-bis-sec-butylaminodiphenylmethane; 25g of composite catalyst. The composite catalyst consists of 6 parts of dipropylene glycol, 3 parts of 1,4-diazabicyclo[2.2.2]octane, 7 parts of dibutyltin diacetate, 11 parts of polyethylene glycol monomethyl ether-polylactide A mixture of polymer surfactants.

[0022] First, fully mix the chain extender and compound catalyst, put the mixed components into the low-pressure foaming machine, fully mix the mixed components and prepolymer according to the ratio of isocyanate index equal to 1, and then put the reaction liquid Inject it into a mold at 80-110°C, demould after 20-40 minutes, and then put it in an oven at 110°C for post-aging for 9-10 hours.

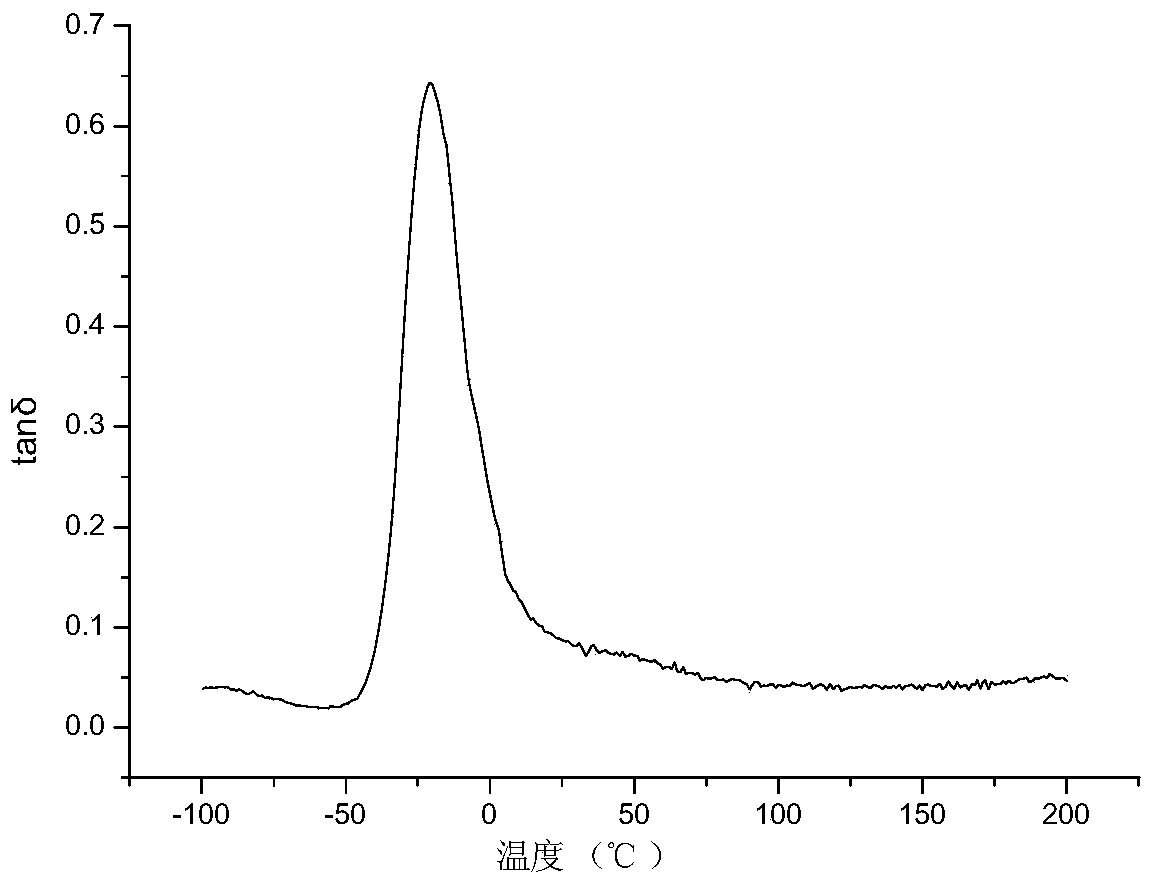

[0023] The product prepared acco...

Embodiment 2

[0028] 1000g of polyadipate-neopentyl glycol with an average relative molecular mass of 2000 and 234g of NDI were reacted at 130°C for 1h to obtain a prepolymer of -NCO%=4.2%; the chain extender component contained 20g of 1,4 -The mixture of butanediol, 10g dimethylthiotoluenediamine and 9.25g N-N' di-sec-butyl-p-phenylenediamine; 30g of composite catalyst. The composite catalyst consists of 6 parts of dipropylene glycol, 3 parts of 1,4-diazabicyclo[2.2.2]octane, 4 parts of dibutyltin diacetate, 20 parts of polyethylene glycol monomethyl ether-polylactide A mixture of polymer surfactants.

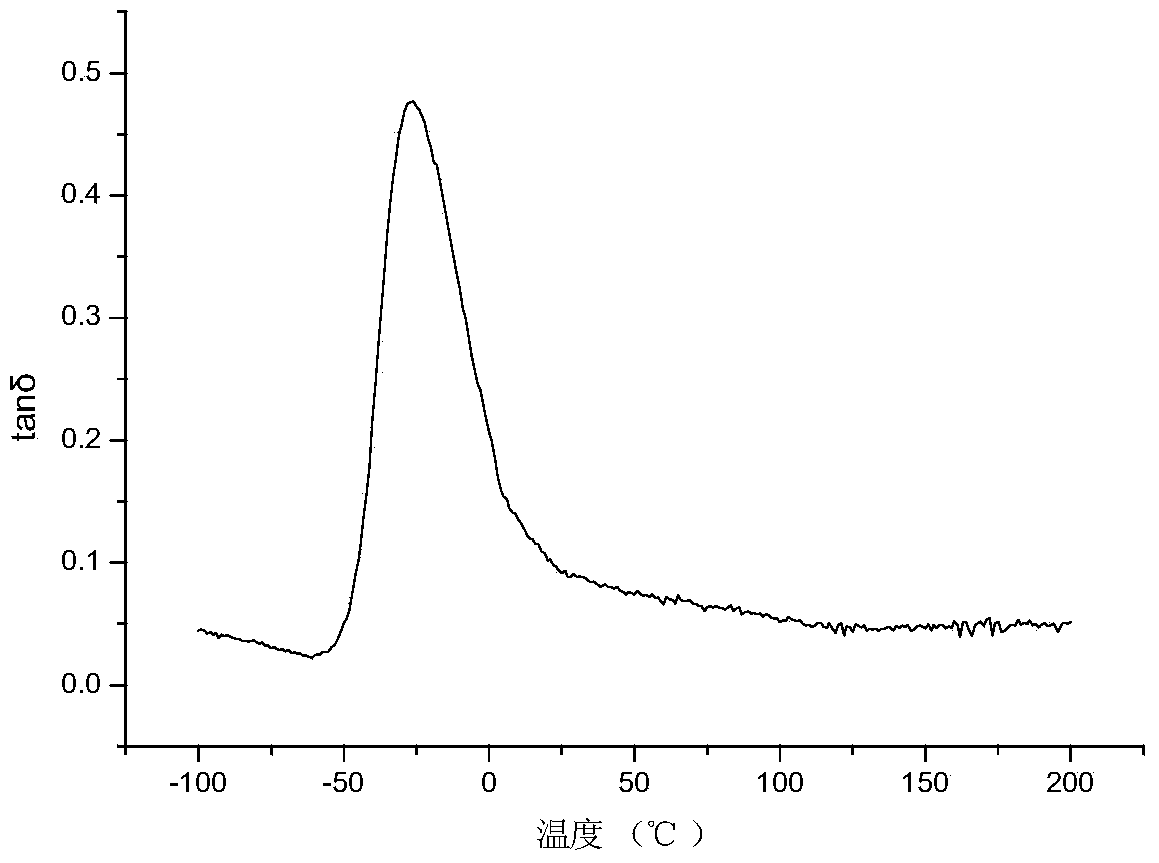

[0029] First, fully mix the chain extender and compound catalyst, put the mixed components into the low-pressure foaming machine, fully mix the mixed components and the prepolymer according to the ratio of isocyanate index equal to 1, and then pour the reaction liquid Pour it into a mold at 80-110°C, demould after 30-45 minutes, and then put it in an oven at 120°C for post-aging for 9-10 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com