High-efficiency treating technology and device for waste water

A technology of treatment process and treatment device, applied in multi-stage water treatment, biological water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of unsatisfactory treatment effect, high cost, inability to popularize and apply, and poor quality of effluent water Discharge requirements and other issues, to achieve the effect of good natural purification ability, high-efficiency bio-augmentation ability, and good nitrogen and phosphorus removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

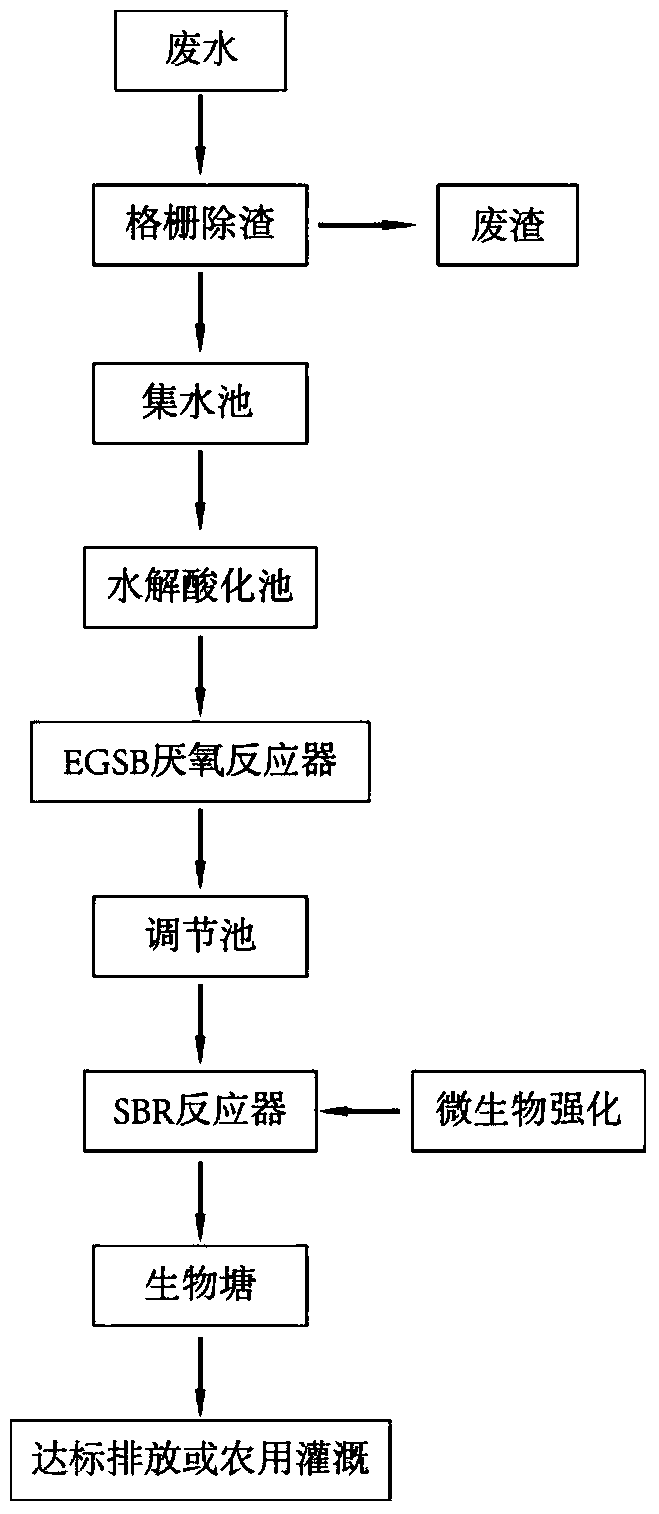

[0052] This embodiment is applied to ten thousand pig farms. According to the combined process route of the present invention, a water collection tank, a hydrolysis acidification tank, an EGSB anaerobic reactor, a regulating tank, an SBR reactor and a biological pond are respectively constructed. The water volume of the pig farm is 150m 3 / d, the raw water quality is COD8000~12000mg / L, NH 3 -N300~1200mg / L, TP40~100mg / L.

[0053] Using this process to treat wastewater, the steps are:

[0054] A. After the wastewater to be treated is collected by the wastewater pipe network, it is intercepted by the grid to remove larger particles and suspended solids in the wastewater.

[0055] B. Secondly, the waste water enters the sump, and the sump plays the role of collecting, storing and balancing the water quality and quantity of the waste water, and adjusting the pH of the water quality. Adjust the pH of the wastewater to between 6 and 9. When the pH value of the water is lower than...

Embodiment 2

[0067] This embodiment is applied to the waste water in the expressway service area, and its water volume is 80m 3 / d, the raw water quality is COD1500mg / L, NH 3 -N130mg / L, TP30mg / L. Its steps are identical with embodiment 1.

[0068] Experimental results:

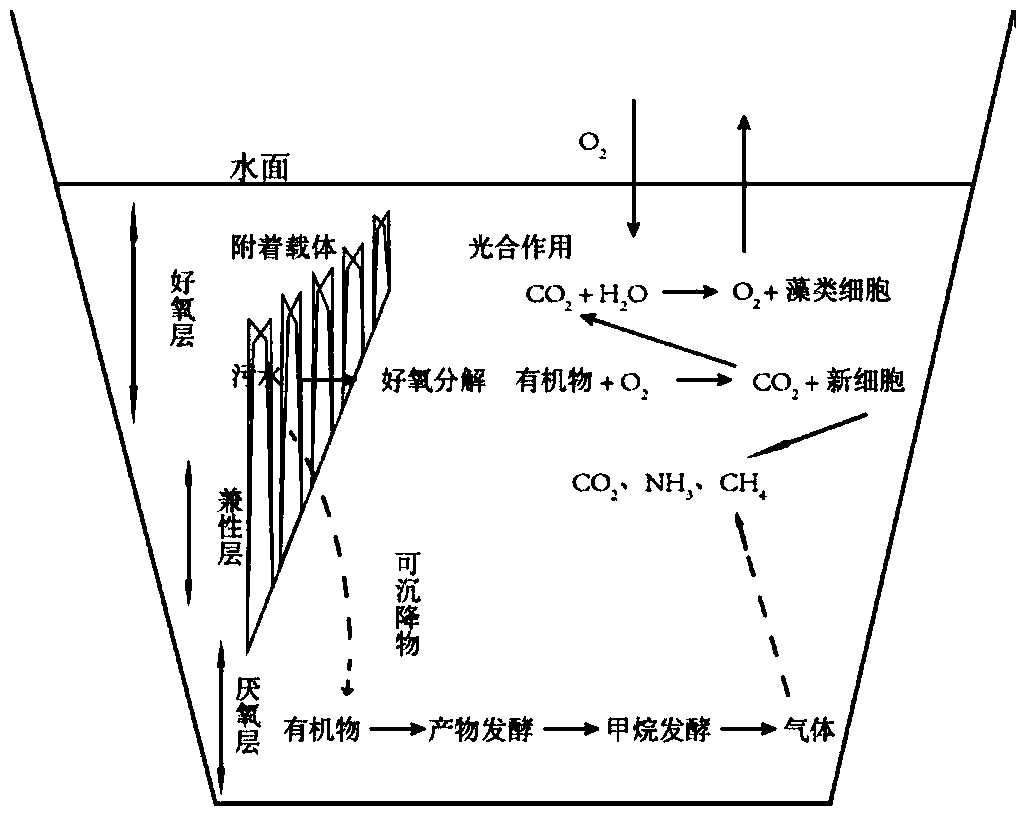

[0069] After the raw water passes through the grid to remove larger particles and suspended solids in the wastewater, it enters the hydrolysis acidification tank to convert macromolecular and refractory organic pollutants into small molecular organic matter, and the effluent enters the EGSB anaerobic reactor, most of the easily degradable organic matter The effluent from the EGSB anaerobic reactor enters the SBR reactor, and through the action of microbial agents, COD, nitrogen and phosphorus are further reduced. The effluent quality after the treatment of the SBR reactor is as follows: COD30~50mg / L, NH 3 -N3~5mg / L, TP0.4~0.5mg / L.

[0070] The effluent is then treated by the biological pond, and the natural purificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com