A kind of titanium alloy tube and its production method

A production method and technology for titanium alloy pipes, which are applied in the directions of pipes, rigid pipes, metal rolling, etc., can solve the problems of many inner surface defects of titanium alloy pipes, difficult grinding of titanium alloy pipes, and low qualified rate of flaw detection, so as to avoid repeated problems. Oxidation and outgassing, avoiding defects, and low inspection pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

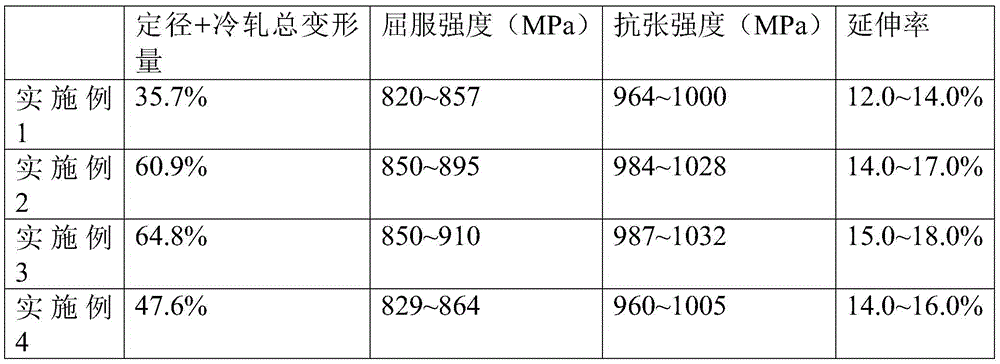

Embodiment 1

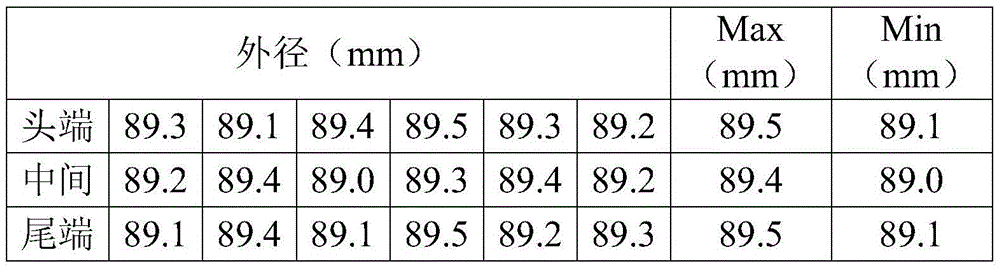

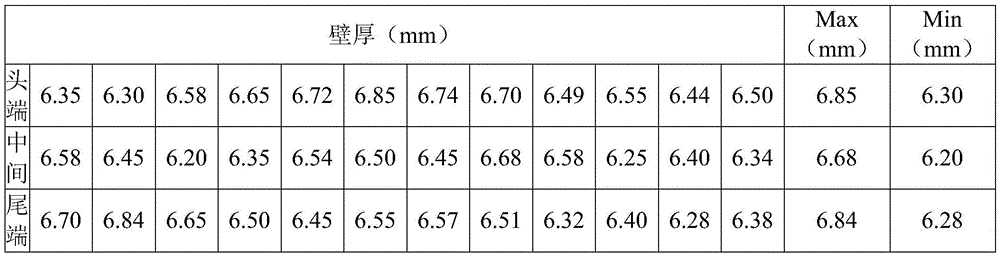

[0091] Example 1: Production Specifications Titanium alloy tube

[0092] Process flow: Packaging after passing.

[0093] The specific production method is as follows: first, the titanium alloy The round blank is placed in an inclined-bottom heating furnace with a micro-oxidizing atmosphere with a volume concentration of 2-5% of the residual oxygen in the furnace and heated to a temperature of 970-990°C and kept at this temperature for 25 minutes to obtain a heated titanium alloy round billet. Blank. made of titanium alloy The round billet is obtained by the manufacturer through smelting, forging and machining in a vacuum consumable electric arc furnace. The quality meets the requirements of cross-rolling and piercing. Its chemical composition is calculated by weight percentage: Al: 6.39%, V: 4.07%, Fe: 0.11 % and the balance Ti, the chemical composition complies with the provisions of GB / T3620.2-2007.

[0094] After the heated titanium alloy round billet comes ou...

Embodiment 2

[0107] Example 2: Production Specifications Titanium alloy tube

[0108] Process flow: Packaging after passing.

[0109] The specific production method is as follows: first, the titanium alloy The round billet is placed in an inclined-bottom heating furnace with a micro-oxidizing atmosphere with a volume concentration of 2-5% of residual oxygen in the furnace and heated to a temperature of 970-990°C and kept at this temperature for 25 minutes to obtain a heated titanium alloy round billet. Blank. made of titanium alloy The round billet is obtained by the manufacturer through smelting, forging and machining in a vacuum consumable electric arc furnace. The quality meets the requirements of cross-rolling and piercing. Its chemical composition is calculated by weight percentage: Al: 6.39%, V: 4.07%, Fe: 0.11 % and the balance Ti, the chemical composition complies with the provisions of GB / T3620.2-2007.

[0110] After the heated titanium alloy round billet comes out o...

Embodiment 3

[0118] Example 3: Production Specifications Titanium alloy tube

[0119] Process flow: Packaging after passing.

[0120] The specific production method is as follows: first, the titanium alloy The round billet is placed in an inclined-bottom heating furnace with a volume concentration of 2-5% of the residual oxygen in the furnace and heated to a temperature of 970-990°C and kept at this temperature for 20 minutes to obtain a heated titanium alloy round billet. Blank. made of titanium alloy The round billet is obtained by the manufacturer through smelting, forging and machining in a vacuum consumable electric arc furnace. The quality meets the requirements of cross-rolling and piercing. Its chemical composition is calculated by weight percentage: Al: 6.39%, V: 4.07%, Fe: 0.11 % and the balance Ti, the chemical composition complies with the provisions of GB / T3620.2-2007.

[0121] After the heated titanium alloy round billet comes out of the furnace, it is transport...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com