Opposite turbulence smoke oven

An oven and turbulent flow technology, which is applied in the field of ovens, can solve the problems of unfavorable large-scale industrial production, easy occurrence of "Maillard reaction, limitation of processing skills, etc., so as to improve operability and safety, and easy to taste. , reduce the effect of Maillard reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

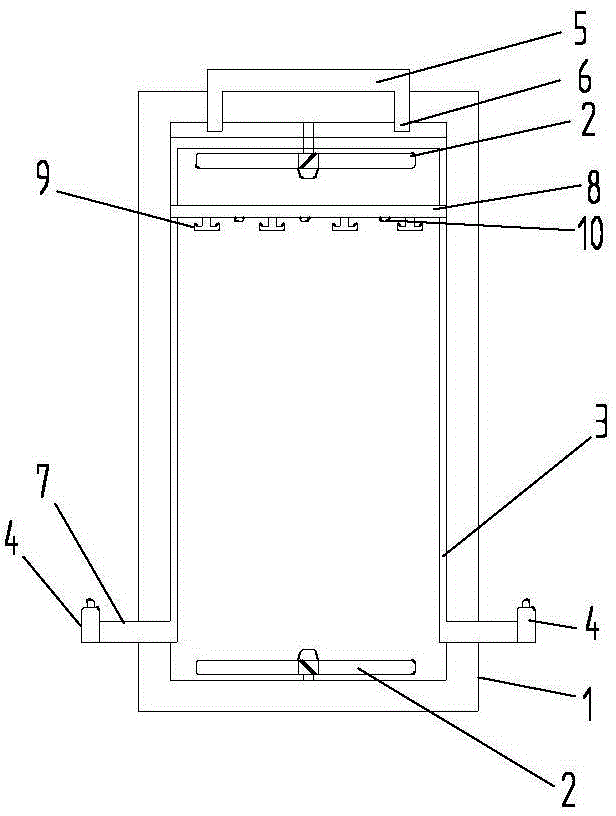

[0018] Such as figure 1 , 2 , 3, and 4, the present invention includes body of heater 1, blower fan 2, heat sink 3, throttle valve 4, body of heater 1 is cylindrical, and upper part of body of heater is provided with smoke generator 5, smoke generator 5 There is a smoke inlet pipe 6 extending into the interior of the furnace body 1 below, and steam pipes 7 are provided on both sides of the furnace body 1, and all steam pipes 7 are provided with throttle valves 4, and heat dissipation is provided around and above the inner wall of the furnace body 1. Sheet 3, heat sink 3 is connected with steam pipe 7, fan 2 is provided at the top and bottom of furnace body 1, fan 2 is centrally symmetrical, crossbeam 8 is provided below fan 2, track 9 is provided below crossbeam 8, and there are 9 rails Be provided with temperature, open flame sensor 10, temperature, open flame sensor 10 is connected with throttling valve 4 by electric wire, furnace body 1 front is provided with furnace door ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com