Heavy rare earth element attachment method for sintered NdFeB magnetic body

A heavy rare earth element and heavy rare earth technology, applied in the direction of magnetic objects, magnetic materials, electrical components, etc., can solve problems such as poor temperature characteristics, low Curie temperature point, inconsistent heavy rare earth concentration, etc., to achieve coercive force improvement, diffusion The effect of large coefficient and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

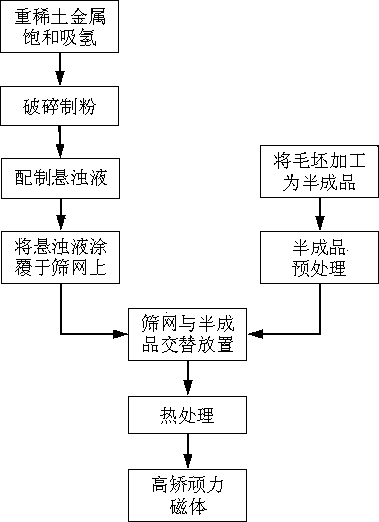

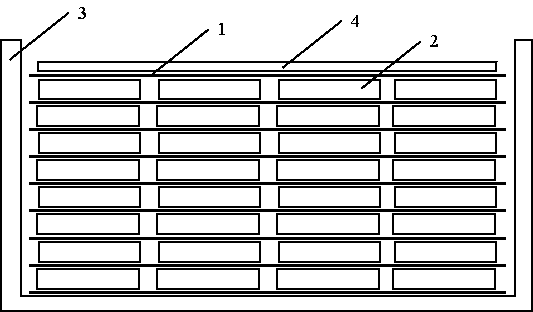

[0034] Such as figure 2 As shown, combined with the above process flow, the metal dysprosium is subjected to saturated hydrogen absorption treatment at 400°C to obtain dysprosium hydride; 2 Under the protection of air, the dysprosium hydride is crushed into a powder with an average particle size of about 2 μm; the above crushed powder is added to gasoline to form a suspension; the suspension is evenly coated with a brush with a mesh number of 200 Both sides of the stainless steel screen 1 are dried; the sintered NdFeB blank is processed into a semi-finished product 2 of 15×15×5 (the direction of size 5 is the orientation direction); the semi-finished product 2 is subjected to pretreatment such as finishing and cleaning to make the surface smooth , clean; the stainless steel screen coated with the suspension and the semi-finished product are alternately placed in the graphite sintering box 3, and the graphite briquetting block 4 is placed on the uppermost layer, and the overal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com