Comprehensive recovery method of tin oxide ore gravity separation tailings

A technology for re-separation of tailings and recovery methods, applied in chemical instruments and methods, improvement of process efficiency, solid separation, etc., can solve the problems of serious pollution, low content, and unrecognized attention, and achieve pollution control and low cost of auxiliary materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

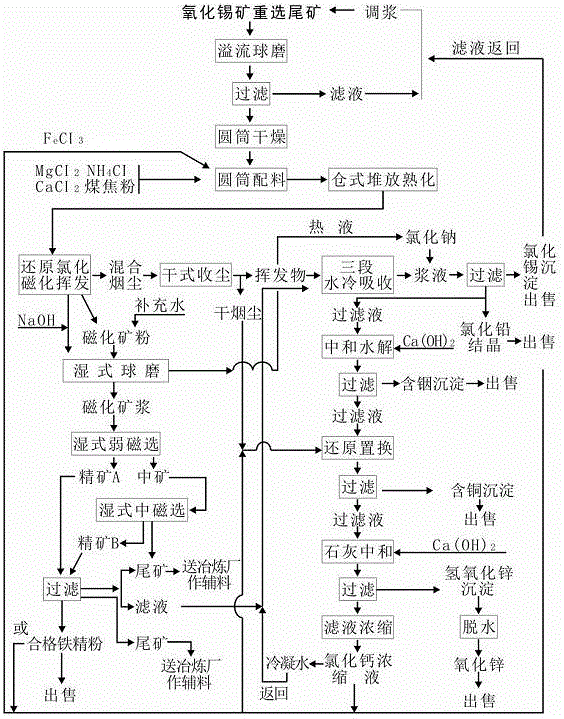

Image

Examples

example 1

[0031] (1) Mix the tin oxide tailings with water to form a raw slurry with a water content of 30% and enter it into wet grinding until the solid particle size is 160-200 mesh pulp. After the wet powder is filtered, it is dehydrated in a drying kiln. After drying, the water content of the mineral powder is 6%, as shown in Table 1. Dry basis composition of general tin oxide gravity separation tailings:

[0032] Table 1. Main chemical composition of tin oxide ore gravity separation tailings on dry basis (%)

[0033] project

Fe

sn

In g / t

Ag g / t

Cu

Pb

Zn

al 2 o 3

S

As

SiO 2

CaO

content

45-48

0.4~0.8

5~10

12~16

0.3~0.7

0.1

0.5~1

1~3

<1

<0.1

5~9

1~3

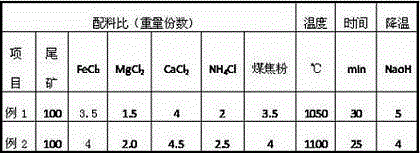

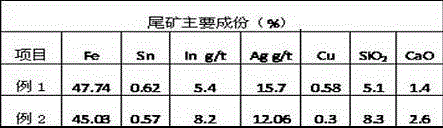

[0034] Table 2 is the composition of two example tin oxide gravity separation tailings:

[0035] Table 2 Dry basis main components of two cases of tin oxide gravity separation tailings

[0036]

[0037] The mineral powder i...

example 2

[0056] CaO / SiO after the dried ore powder and auxiliary material batching described in step (2) 2 The ratio is 0.83.

example 3

[0058] According to the principle that the higher the copper content in the tailings slag of the gravity separation of tin oxide ore, the higher the length-to-diameter ratio, the length-to-diameter ratio of the roasting kiln in step (3) should be properly selected in the range of (15-17):1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com