Modified adhesive

A binder and modification technology, applied in the direction of adhesives, adhesive types, starch adhesives, etc., can solve the problems of mildew, affecting appearance and use, unavoidable formaldehyde, etc., to increase bactericidal properties and prevent Mildew, good stability and dispersibility, and the effect of preventing the binder from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

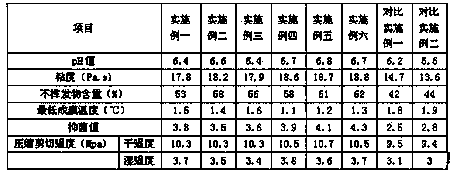

Examples

Embodiment 1

[0046] Preparation of nano silver:

[0047] (1) Add sodium dodecyl sulfonate solution, water-based polyacrylate and hydrazine hydrate solution to silver nitrate aqueous solution to obtain a mixed solution. The molar ratio of sodium dodecyl sulfonate to silver nitrate is 4:1; water-based The molar ratio of polyacrylate to silver nitrate is 0.4:1; the molar ratio of hydrazine hydrate to silver nitrate is 0.2:1;

[0048] (2) Add dicyclohexyl-18-crown-6 and sodium metaphosphate to the mixture, the molar ratio of dicyclohexyl-18-crown-6 to silver nitrate is 3:1; sodium metaphosphate and The molar ratio of silver nitrate is 0.8:1, and the pH value is controlled to be 8-9 to obtain nano silver.

[0049] The concrete preparation method of bamboo charcoal powder is:

[0050] a. Raw material pre-treatment: send the bamboo into a microwave vacuum tank, evacuate until the vacuum degree is -0.01MPa, and then perform microwave treatment, the microwave frequency is 650MHz, and the microwa...

Embodiment 2

[0066] Preparation of nano silver:

[0067] (1) Add sodium dodecyl sulfonate solution, water-based polyacrylate and hydrazine hydrate solution to silver nitrate aqueous solution to obtain a mixed solution. The molar ratio of sodium dodecyl sulfonate to silver nitrate is 6:1; The molar ratio of polyacrylate to silver nitrate is 0.6:1; the molar ratio of hydrazine hydrate to silver nitrate is 0.3:1;

[0068] (2) Add dicyclohexyl-18-crown-6 and sodium metaphosphate to the mixture, the molar ratio of dicyclohexyl-18-crown-6 to silver nitrate is 5:1; sodium metaphosphate and The molar ratio of silver nitrate is 1.3:1, and the pH value is controlled to be 8-9 to obtain nano silver.

[0069] The composition ratio of the modified binder:

[0070] 35 parts of phthalic anhydride, 11 parts of furfuryl alcohol extracted from oat or wheat bran, 12 parts of triethylene glycol, 18 parts of glutaric acid, 10 parts of butanetriol, 7 parts of zinc oxide powder, 5 parts of magnesium oxide, chl...

Embodiment 3

[0083] Preparation of nano silver:

[0084] (1) Add sodium dodecyl sulfonate solution, water-based polyacrylate and hydrazine hydrate solution to silver nitrate aqueous solution to obtain a mixed solution. The molar ratio of sodium dodecyl sulfonate to silver nitrate is 5:1; water-based The molar ratio of polyacrylate to silver nitrate is 0.5:1; the molar ratio of hydrazine hydrate to silver nitrate is 0.25:1;

[0085](2) Add dicyclohexyl-18-crown-6 and sodium metaphosphate to the mixture, the molar ratio of dicyclohexyl-18-crown-6 to silver nitrate is 4:1; sodium metaphosphate and The molar ratio of silver nitrate is 1:1, and the pH value is controlled to be 8-9 to obtain nano silver.

[0086] The composition ratio of the modified binder:

[0087] 30 parts of phthalic anhydride, 7-11 parts of furfuryl alcohol extracted from bamboo sawdust, 11 parts of triethylene glycol, 16 parts of glutaric acid, 9 parts of butanetriol, 6 parts of zinc oxide powder, 4 parts of magnesium ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com