Radiation-resistant glass fiber and needled felt prepared from same

A glass fiber, radiation-resistant technology, applied in the direction of non-woven fabrics, textiles and paper, to achieve the effect of improving thermal insulation effect and construction efficiency, low moisture absorption, good elasticity and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The raw material components of glass fiber are listed in Table 1. The fiber is drawn by a general-purpose crucible or pool kiln, and the glass fiber is drawn into a continuous strand with an average diameter of 7 μm, and the strand is chopped into a chopped strand with a length of 60 mm. , the chopped strands are carded, laid, and needle-punched to form a density of 65kg / m 3 Needle-punched felt, the material is placed in an environment of 50°C and humidity of 95% for 96h, the mass moisture absorption rate is 0, the thermal load shrinkage temperature of the fiber felt is 670°C, and the engineering thermal conductivity is 0.033W / m·K (50 ℃), 0.055W / m·K (200℃).

[0022] Table 1

[0023]

Embodiment 2

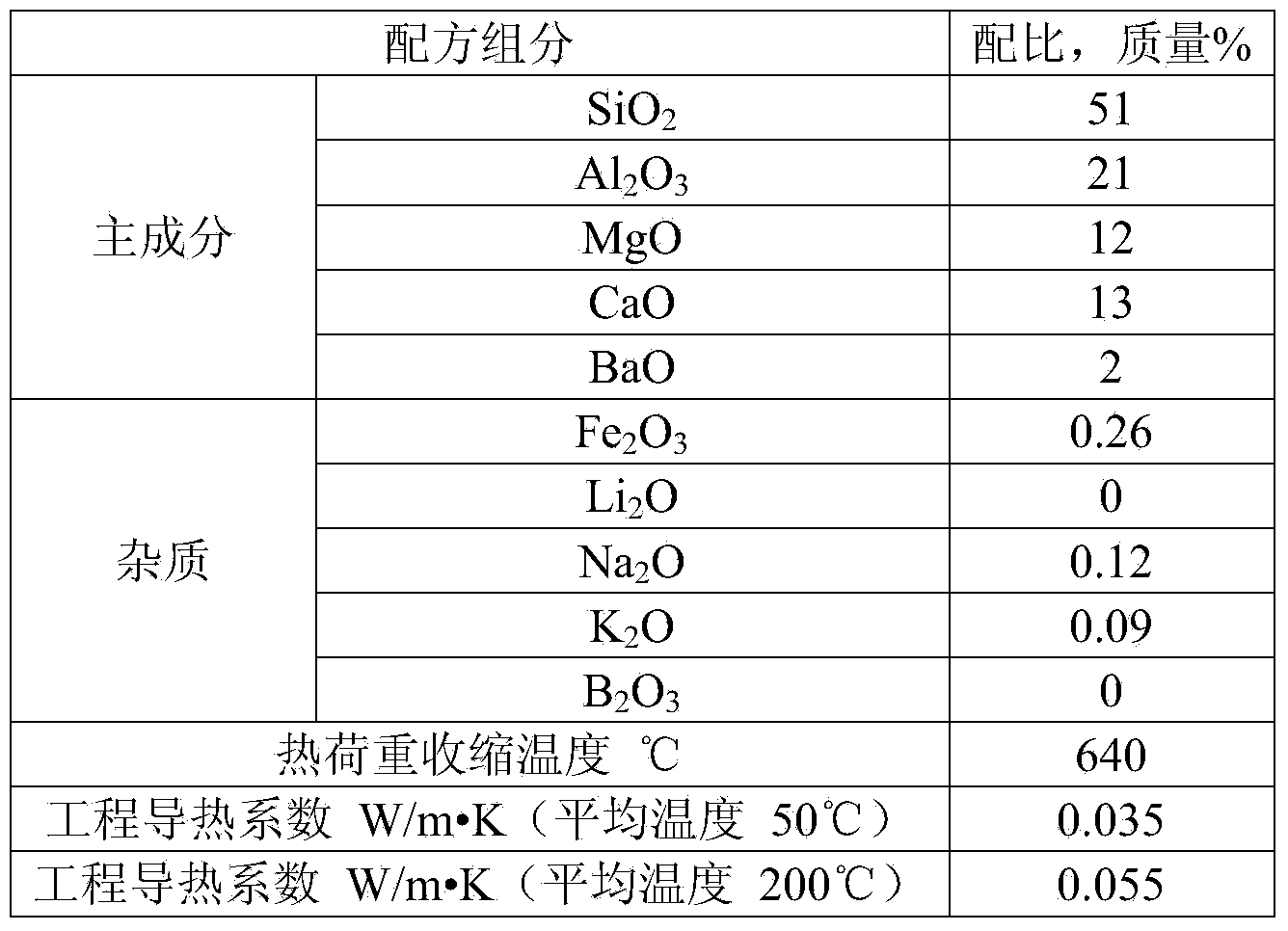

[0025] The raw material components of glass fiber are listed in Table 2. The fiber is drawn by a general-purpose crucible or pool kiln, and the glass fiber is drawn into a continuous strand with an average diameter of 6.9 μm, and the strand is chopped into a chopped strand with a length of 60 mm. Silk, chopped strands are carded, laid, and needle-punched to form a density of 72kg / m 3 Needle-punched felt, the material is placed in an environment of 50°C and humidity of 95% for 96h, the mass moisture absorption rate is 0, the thermal load shrinkage temperature of the fiber felt is 640°C, and the engineering thermal conductivity is 0.035W / m·K (50 ℃), 0.055W / m·K (200℃).

[0026] Table 2

[0027]

Embodiment 3

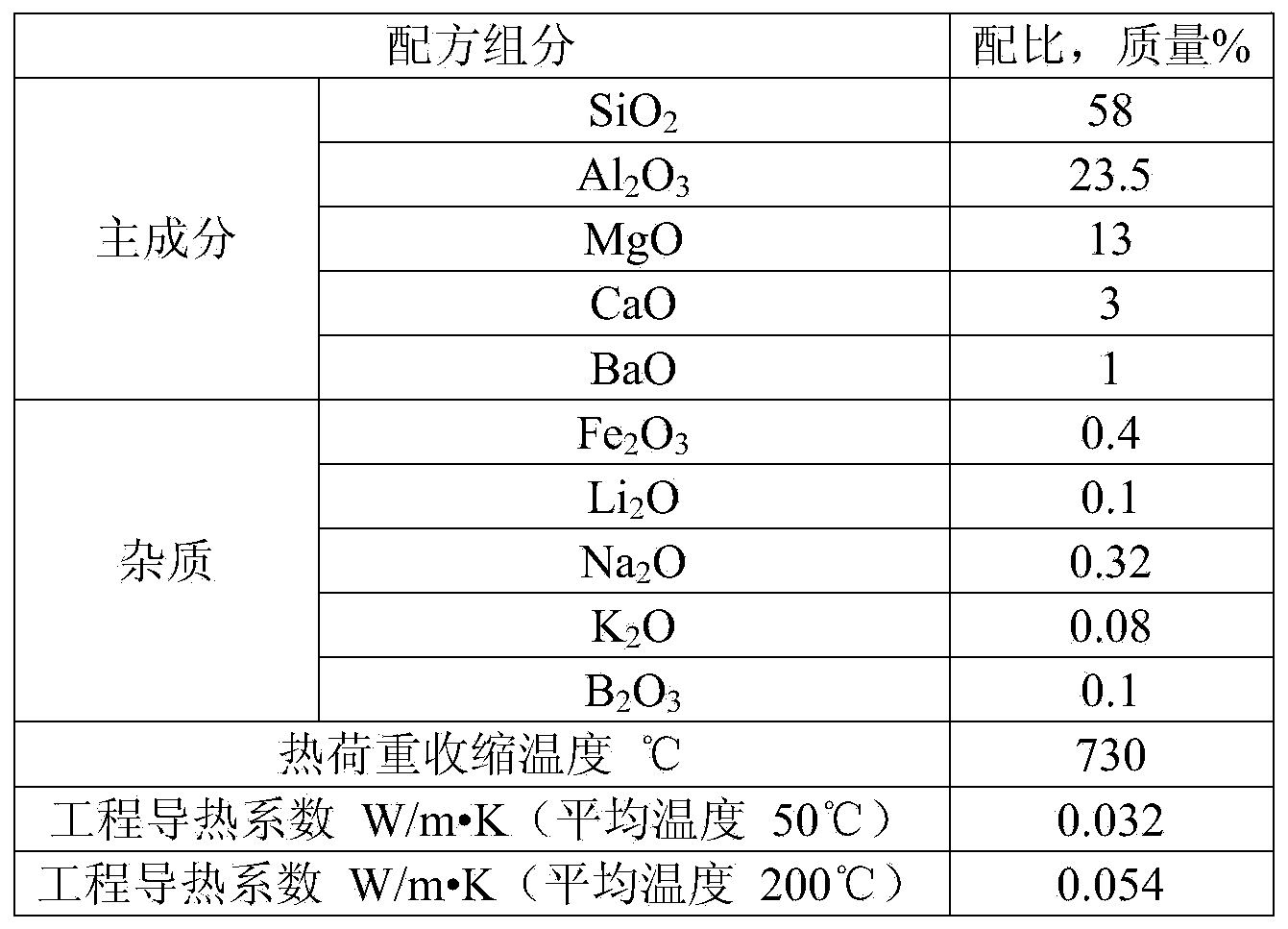

[0029] The raw material components of glass fiber are listed in Table 3. The fiber is drawn by a general-purpose crucible or pool kiln, and the glass fiber is drawn into a continuous strand with an average diameter of 9 μm, and the strand is chopped into a chopped strand with a length of 60 mm. , Chopped strands are formed with a density of 75kg / m after carding, laying, and acupuncture processes 3 Needle-punched felt, the material is placed in an environment of 50°C and humidity of 95% for 96h, the mass moisture absorption rate is 0, the thermal load shrinkage temperature of the fiber felt is 720°C, and the engineering thermal conductivity is 0.032W / m·K (50 ℃), 0.054W / m·K (200℃).

[0030] table 3

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com