Method and equipment for coating metal bond on abrasive particle

A metal bond, abrasive particle technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of uneven distribution of abrasive particles, waste of abrasives, segregation, etc., to achieve the effect of simple process and overcoming poor adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

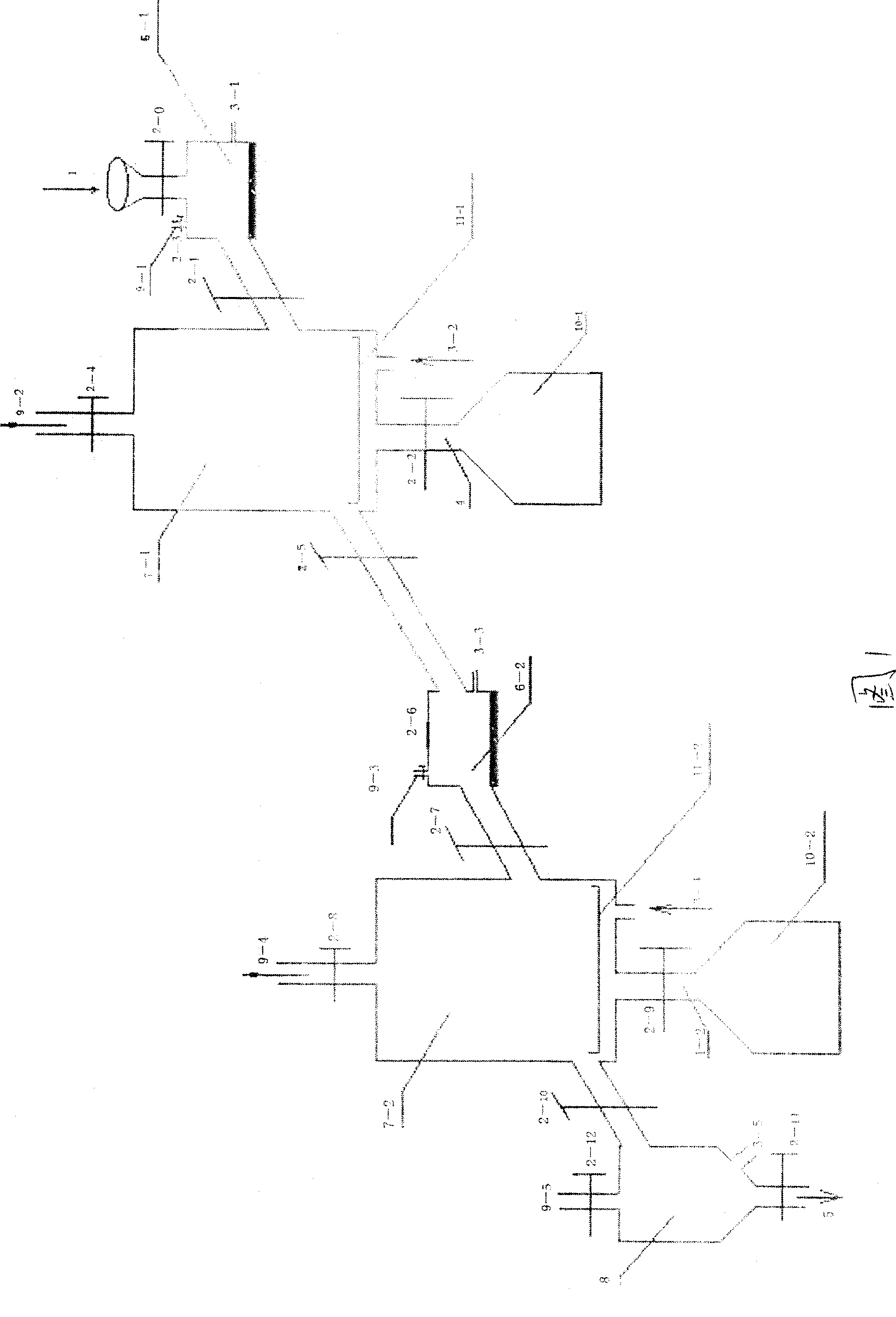

[0017] The method comprises the following steps: first, the abrasive grains with a clean surface and no pollution are placed in the heating chamber 6. In order to prevent the abrasive grains from being oxidized during the heating process, the heating chamber must be treated under a protective atmosphere such as vacuum or nitrogen or argon. Abrasive grains are heated, and the lower limit of temperature should be higher than the boiling point of the metal carbonyl complex used for coating, and the upper limit of temperature should not reduce the abrasive strength; secondly, the abrasive grains heated to the required temperature are transported to a vibrating or agitator 11 In the coating chamber 7, open the metal carbonyl complex vapor inlet 4, input the metal carbonyl complex vapor into the coating chamber 7, and start the vibration or agitator 11 to coat at the same time; finally, the coated abrasive is transported to the cooling chamber. The passivation chamber 8 cools the pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com