Continuous-fiber reinforced thermoplastic polymer temperature-adjusting plate

A technology of reinforced thermoplastic and continuous fiber, which is applied in the field of construction or decorative boards. It can solve the problems of weak bonding, easy corrosion and rust, and affecting strength, so as to improve the temperature adjustment effect, facilitate coloring, and improve strength and bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

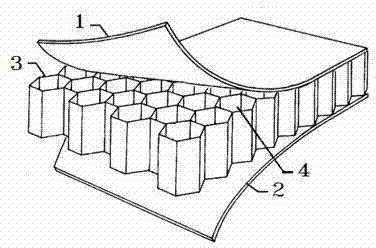

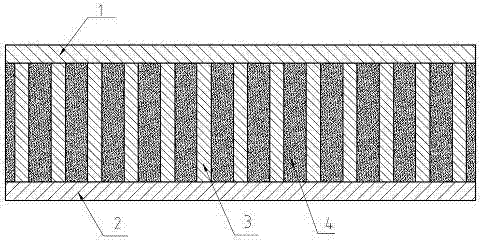

[0025] The composite materials used include glass fiber, polypropylene, graphite and calcium carbonate, among which, based on 100 parts by weight of thermoplastic polymer and modified thermally conductive filler, polypropylene is 85 parts by weight, graphite is 10 parts by weight, and calcium carbonate is 5 parts by weight. . Polypropylene, graphite, and calcium carbonate are blended and plasticized by an extruder and then mixed with glass fiber by a double-sided coating method to prepare continuous fiber reinforced thermoplastic polymer composite sheet. The thickness of the continuous fiber reinforced thermoplastic polypropylene composite sheet The honeycomb core layer is prepared from the continuous fiber reinforced thermoplastic polypropylene composite material sheet prepared by molding and bonding, and the thickness of the honeycomb core layer is 5mm; the phase change energy storage material is selected as the phase change energy storage material. The change point is 21°C. ...

Embodiment 2

[0029] The composite materials used include carbon fiber, polyamide, aluminum nitride and alumina, wherein, based on 100 parts by weight of thermoplastic polymer and modified thermally conductive filler, polyamide is 80 parts by weight, aluminum nitride is 10 parts by weight, and alumina is 10 parts by weight. Polyamide, aluminum nitride and alumina are blended and plasticized by an extruder and then mixed with carbon fiber by a double-sided coating method to prepare continuous fiber reinforced thermoplastic polymer composite sheets, and continuous fiber reinforced thermoplastic polyamide composite sheets The thickness of the honeycomb core layer is 0.6mm; the honeycomb core layer is prepared by rolling and bonding the prepared continuous fiber reinforced thermoplastic polyamide composite material sheet, and the thickness of the honeycomb core layer is 10mm; the phase change energy storage material uses composite phase change energy storage Material, the phase transition point ...

Embodiment 3

[0034] The composite material used includes aramid fiber, polycarbonate, silicon nitride and metal powder, among which, based on 100 parts by weight of thermoplastic polymer and modified thermally conductive filler, 90 parts by weight of polycarbonate and 5 parts by weight of silicon nitride , The metal powder is 5 parts by weight. Polycarbonate, silicon nitride and metal powder are blended and plasticized by an extruder and then mixed with aramid fiber by double-sided coating method to prepare continuous fiber reinforced thermoplastic polycarbonate composite sheet, continuous fiber reinforced thermoplastic polycarbonate The thickness of the composite material sheet is 1.0mm; the honeycomb core layer is prepared by the continuous fiber reinforced thermoplastic polycarbonate composite material sheet prepared by roll bonding, and the thickness of the honeycomb core layer is 20mm; phase change energy storage material The phase change energy storage material is selected, and the ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com