Compositing method of dovetail groove metal plate clearance fit interface

A technology of interfacial compounding and dovetail groove, which is applied in metal processing, metal processing equipment, non-electric welding equipment, etc., can solve problems such as the technical report of dovetail groove interfacial compounding and difficulty in rolling process, etc., so as to save explosives, save Recombination time, effect of small amount of explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

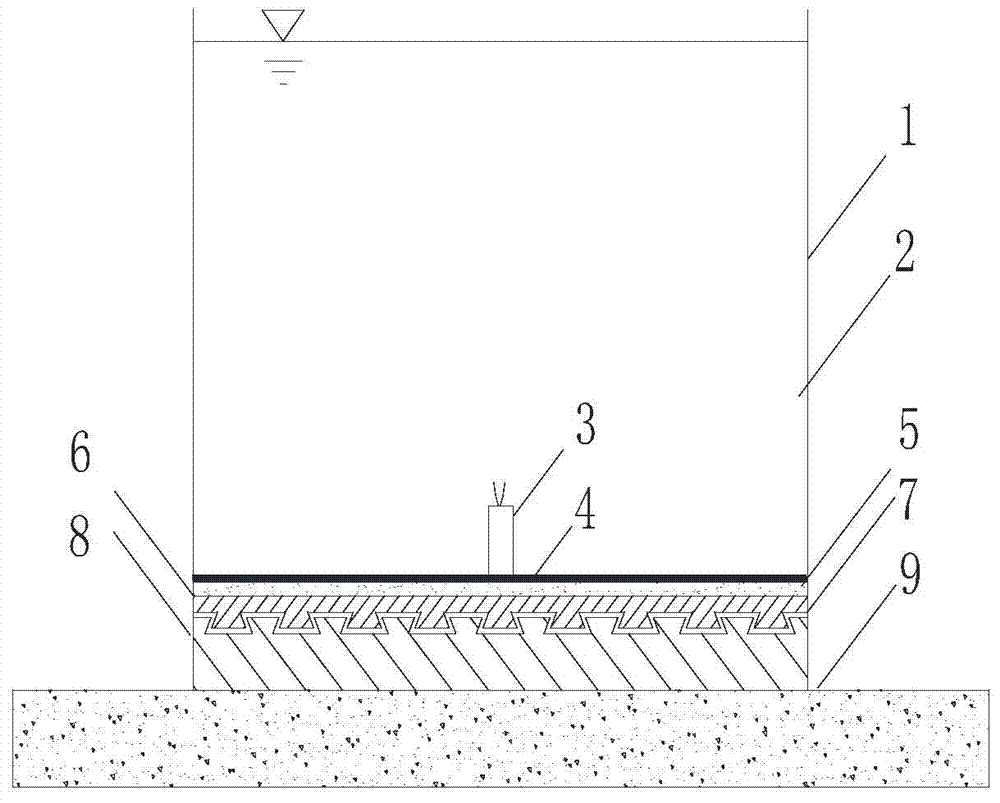

[0027] The cladding plate and base plate are made of stainless steel and Q235 steel plate respectively, and the dimensions are 200mm×100mm×3mm and 200mm×100mm×18mm respectively. Dovetail grooves with dimensions of 2mm on the upper bottom, 3mm on the lower bottom, and 1mm in height are produced every 3mm on the surface of the substrate. figure 1 shown. Bonded explosives are used for the metal plate composite, the ratio of RDX and nitrocellulose is 95:5, the size is 200mm×100mm×1mm, the mass is 35g, and the size of the aluminum plate is 200mm×100mm×2mm. The schematic diagram of the experimental device is as follows figure 2 shown. Experimental steps: (1) Use sandpaper to polish the front, back and surroundings of the cladding plate 7 and the base plate 8 to make the surface of the metal plate smooth and smooth, and then scrub the surface to be bonded with alcohol. (2) After placing a powder frame with a height of 1 mm on the surface of the aluminum plate 4, spread the explosi...

Embodiment 2

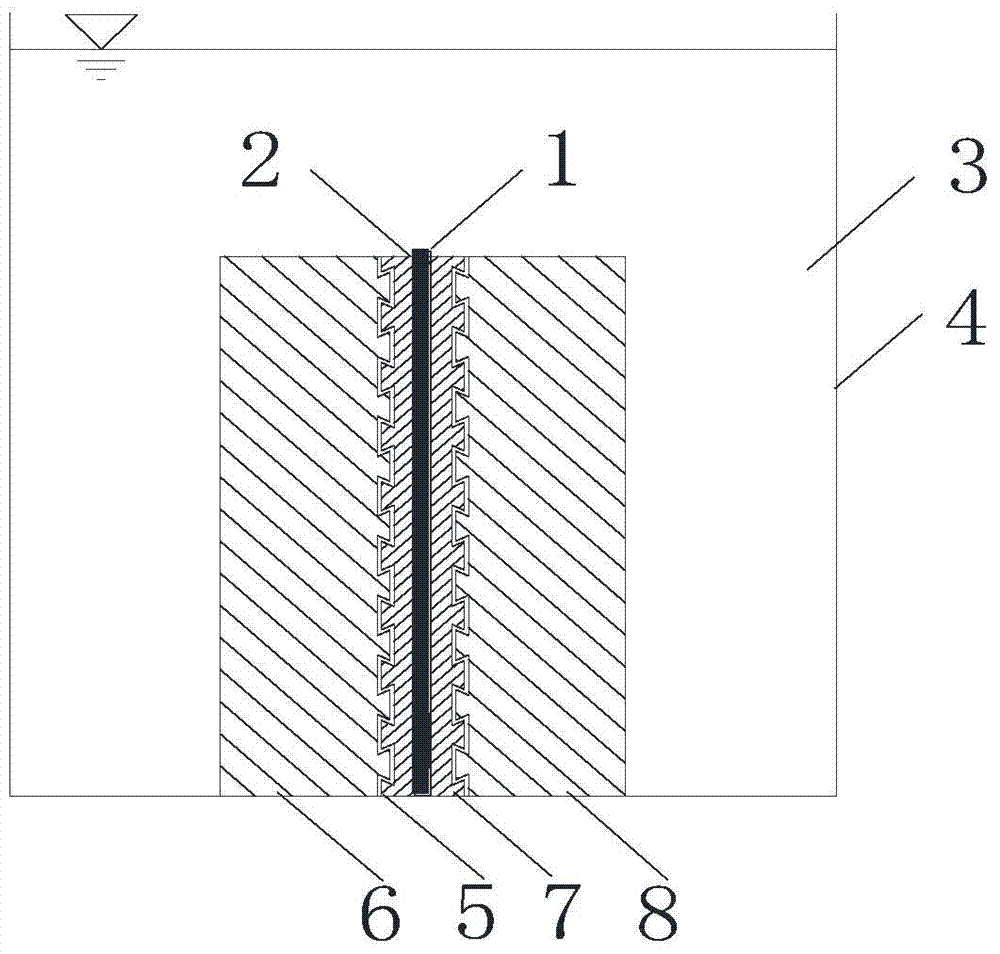

[0029]In this experiment, copper plate and Q235 steel plate were selected as cladding plate and substrate of metal plate composite, and the dimensions were 150mm×150mm×3mm and 150mm×150mm×18mm respectively. Dovetail grooves of 2mm on the upper bottom, 3mm on the lower bottom, and 1mm in height are formed on the surface of the substrate at intervals of 3mm, while dovetail grooves with the same shape as the substrate are formed on the surface of the cladding plate to ensure a clearance fit with the substrate, such as figure 1 shown. The size of the bonded explosive is 165mm×150mm×1mm, and the mass is 45g. In this experiment, the double-sided composite method is used for metal plate composite, such as image 3 shown. Experimental steps: (1) Use sandpaper to polish the front and back surfaces of the substrates 6, 8 and the cover plates 5, 7 and their surroundings to make the surface of the metal plates smooth and smooth, and then use alcohol to clean the surfaces to be bonded. ...

Embodiment 3

[0031] In this experiment, stainless steel plate and Q235 steel plate are used as cladding plate and substrate of metal plate composite, and the dimensions are 150mm×150mm×2mm and 150mm×150mm×18mm respectively. Dovetail grooves of 2mm on the upper bottom, 2.5mm on the lower bottom, and 0.5mm in height are formed on the surface of the substrate at intervals of 2.5mm. Figure 5 shown. In this experiment, emulsified explosives were used for metal plate composite, the ratio of emulsified matrix to glass microspheres was 96:4, the size was 150mm×150mm×5mm, and the mass was 125g. The upper surface of the emulsion explosive is covered with an aluminum plate with a size of 150mm×150mm×2mm to strengthen the restraint and ensure the stable explosion of the explosive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com