Preparation method of carbon based catalyst with high graphitization degree and used for fuel cell cathode

A fuel cell cathode, carbon-based catalyst technology, applied in physical/chemical process catalysts, battery electrodes, chemical instruments and methods, etc., can solve problems such as pore collapse of materials, limitation of industrialized large-scale production, reduction of specific surface area and pore volume, etc. , to achieve the effect of improving performance, enhancing oxygen reduction catalytic activity, and increasing active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

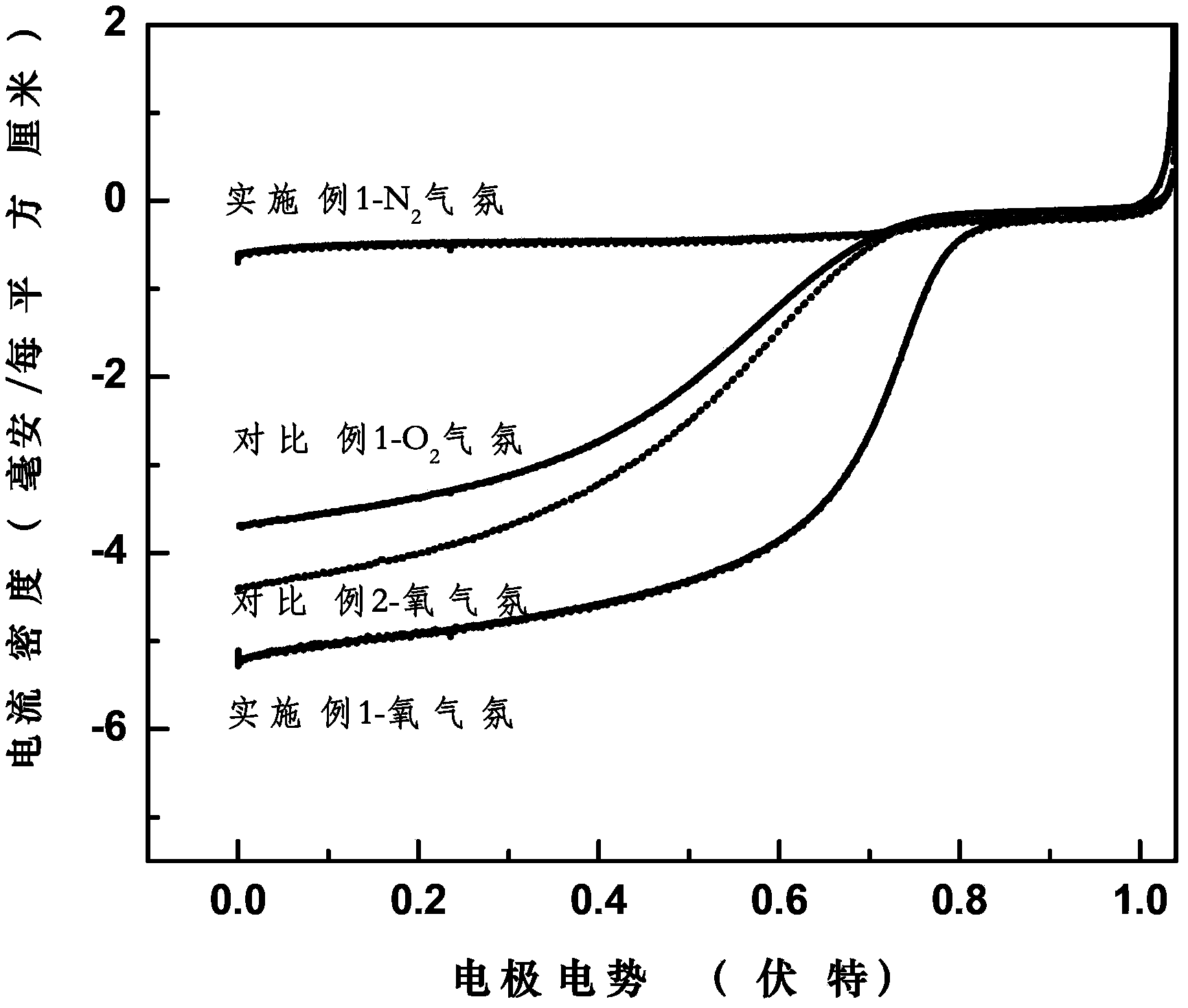

Embodiment 1

[0036] Heat 1.0 g of pitch to softening temperature of 200 °C to form molten precursor A; 50 nm nanometer-sized CaCO 3 Add the hard template to A, and keep stirring to make it evenly mixed to obtain a mixture B, wherein the mass ratio of the hard template to asphalt is 1:2; add a nitrogen-containing precursor to the mixture B, keep stirring for more than 1 hour, and mix evenly , to obtain mixture C, wherein the molar mass ratio of nitrogen-containing precursor hexamethylene diammonium to asphalt is 1:100; the metal salt solution is added to C with the molar ratio of ferric nitrate and asphalt being 1:30, and the stirring is continued to obtain mixture D ; Mixture D was heated at 900°C in NH 3Carbonization treatment under atmosphere protection conditions for 2 hours to obtain solid powder E; soak solid powder E in 1M dilute acid solution for 24 hours, wash, dry, and ball mill to obtain carbon-based catalyst H of the present invention.

Embodiment 2

[0045] Heat 0.5g of asphalt to a softening temperature of 280°C to form a molten precursor A; add 30nm nanometer-sized MgO hard template to A, and keep stirring to make it evenly mixed to obtain a mixture B, in which MgO and asphalt The mass ratio is 1:2; add nitrogen-containing precursor melamine to mixture B, continue to stir for 2 hours, and mix uniformly to obtain mixture C, wherein the molar mass ratio of nitrogen-containing precursor to asphalt is 1:100; Add metal salt solution to C at a ratio of 1:50, and continue to stir to obtain mixture D; carbonize mixture D at 800°C under ammonia atmosphere protection conditions for 2 hours to obtain solid powder E; solid powder E at 0.5 Soak M in a dilute acid solution for 24 hours, wash, dry, and ball mill for 3 hours to obtain the carbon-based catalyst H of the present invention.

Embodiment 3

[0047] Heat 0.5g of pitch to the softening temperature of 180°C to form molten precursor A; put 0.5g of SiO 2 (SBA-15) Add the hard template to A, and keep stirring to make it mix uniformly to obtain mixture B; add nitrogen-containing precursor melamine to mixture B, continue stirring for 2 hours, and mix uniformly to obtain mixture C, which contains nitrogen The molar mass ratio of the precursor to the asphalt is 1:300; the metal salt solution is added to C with the molar ratio of cobalt nitrate and asphalt being 1:20, and the stirring is continued to obtain the mixture D; the mixture D is protected in a nitriding atmosphere at 1000 Carbonization treatment under conditions for 2 hours to obtain solid powder E; soak solid powder E in 0.5M dilute acid solution for 24 hours, wash, dry, and ball mill for 3 hours to obtain carbon-based catalyst H of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com