Insulating rod for 500kV equipment high-voltage test working

A high-voltage test and insulating rod technology, which is applied to the parts, measuring devices, instruments and other directions of electrical measuring instruments, can solve the problems that the insulating rod cannot be hung firmly, the test line cannot be suspended, and the suspension of the insulating rod is difficult. The effect of testing data accuracy, enhancing work safety, and reducing the risk of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

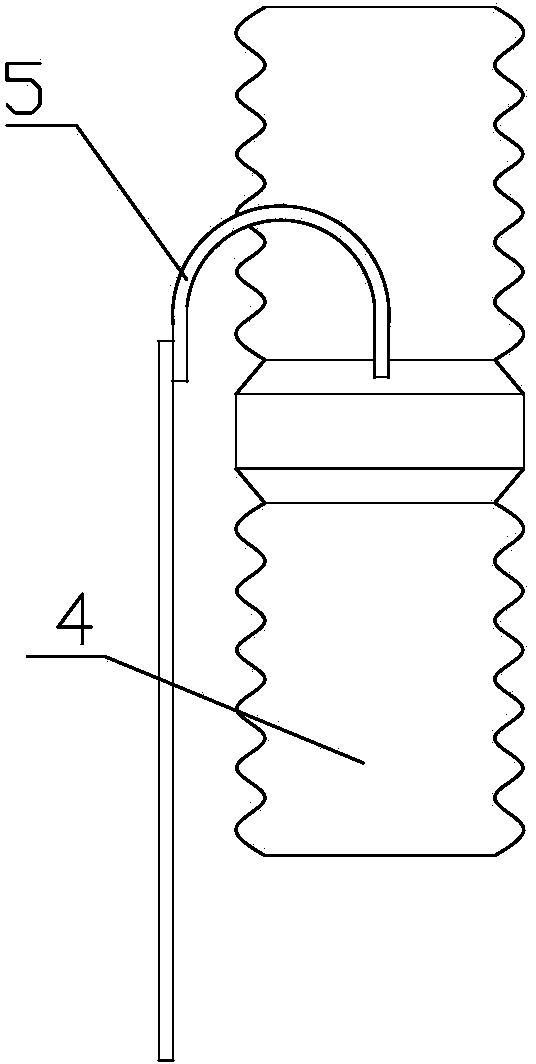

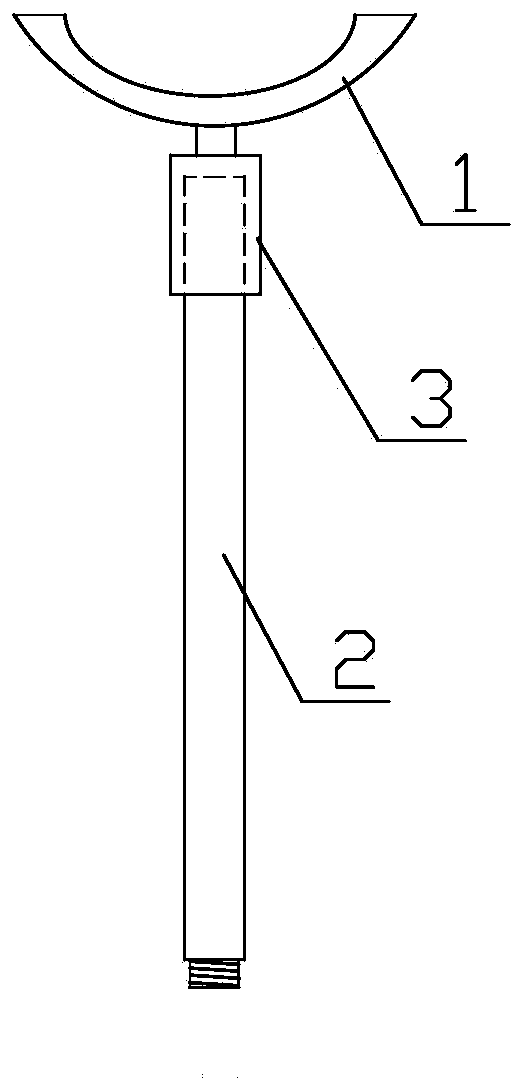

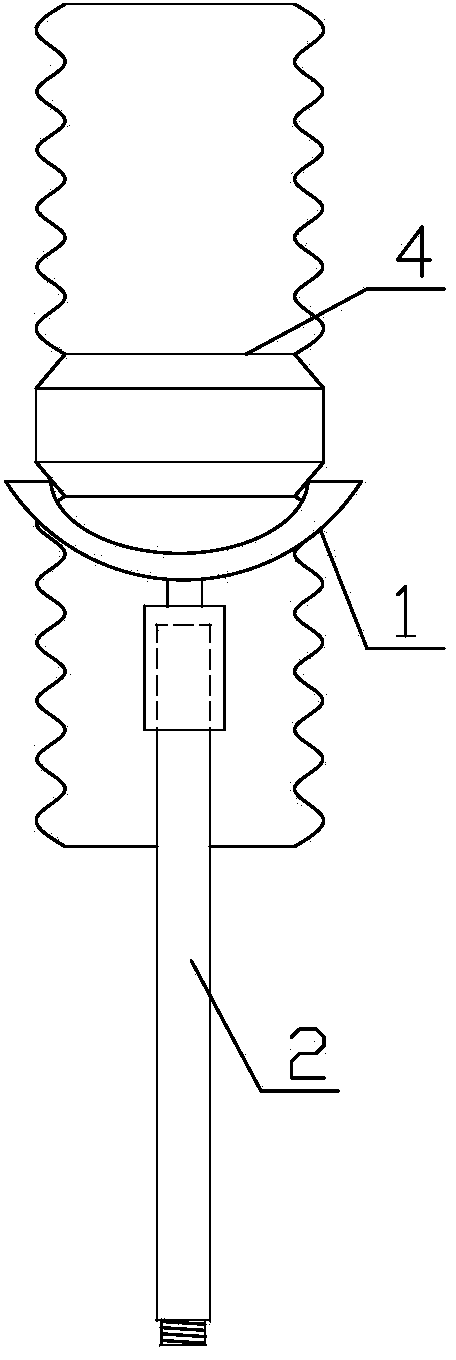

[0015] See figure 2 , image 3 , the insulating rod used for the high-voltage test operation of 500kV equipment, including the insulating rod head 1 and the insulating rod body 2, the insulating rod head 1 is an arc-shaped structure, and is connected with the insulating rod body 2 in the middle of the arc-shaped structure. Among them, a threaded sleeve 3 is welded in the middle of the insulating rod head 1, and the insulating rod body 2 and the insulating rod head 1 are connected through the threaded sleeve 3; the arc-shaped structure matches the equipment under test.

[0016] According to the size of the upper section of the existing insulating rod body 2, a threaded sleeve 3 that can match the insulating rod body 2 is manufactured, and an ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com