Minimum leak rate calibrating method based on static ion flow rising rate comparison method

A static ion flow, extremely small leak rate technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc., can solve the problem of the extremely small leak rate signal being submerged by the background, etc. , to achieve the effect of enhancing signal strength, increasing concentration, improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

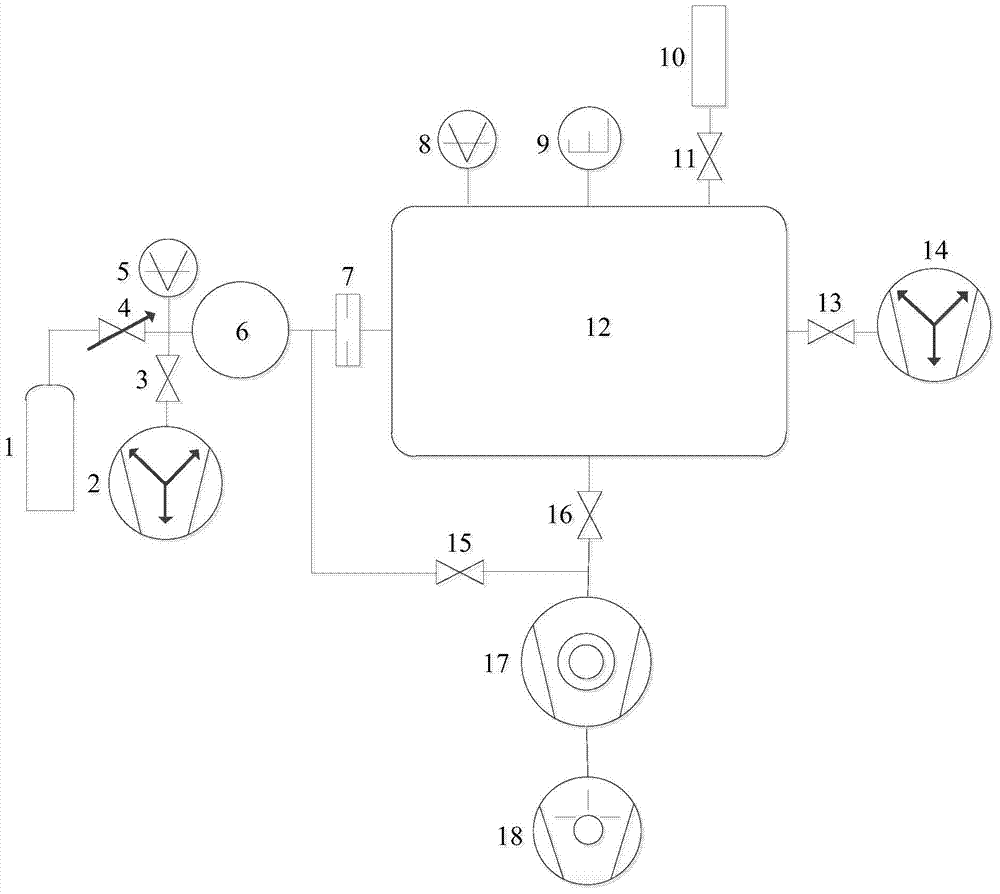

[0026] The present invention provides a method for calibrating a very small leak rate using a static ion current rising rate comparison method. figure 1The detection device shown is calibrated, and the detection device includes a gas cylinder 1, a non-evaporative getter pump a 2, a non-evaporative getter pump b 14, a stop valve a 3, a stop valve b 11, a stop valve c 13. Globe valve d 15, globe valve e 16, trim valve 4, vacuum gauge a 5, vacuum gauge b 8, pressure chamber 6, small hole piece 7, quadrupole mass spectrometer 9, minimum leak rate calibrated piece 10 , calibration chamber 12 , molecular pump 17 and dry pump 18 . Wherein, the series pumping system composed of the molecular pump 17 and the dry pump 18 is connected to the lower part of the calibration chamber 12 through the cut-off valve e 16, for pumping the calibration chamber 12 to ultra-hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com