Microwave vacuum air pressure sintering furnace

A technology of air pressure sintering and microwave vacuum, which is applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of low reaction temperature of microwave air pressure equipment, inability to apply pressure by microwave sintering equipment, and long production cycle, etc., to achieve high density, Good uniformity and fast sintering speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered.

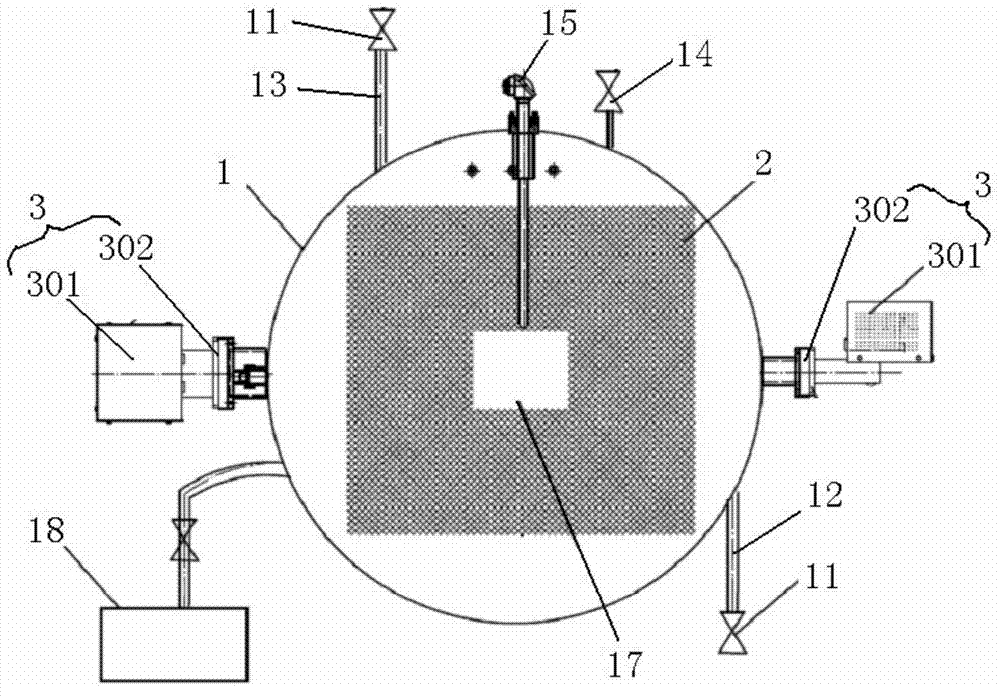

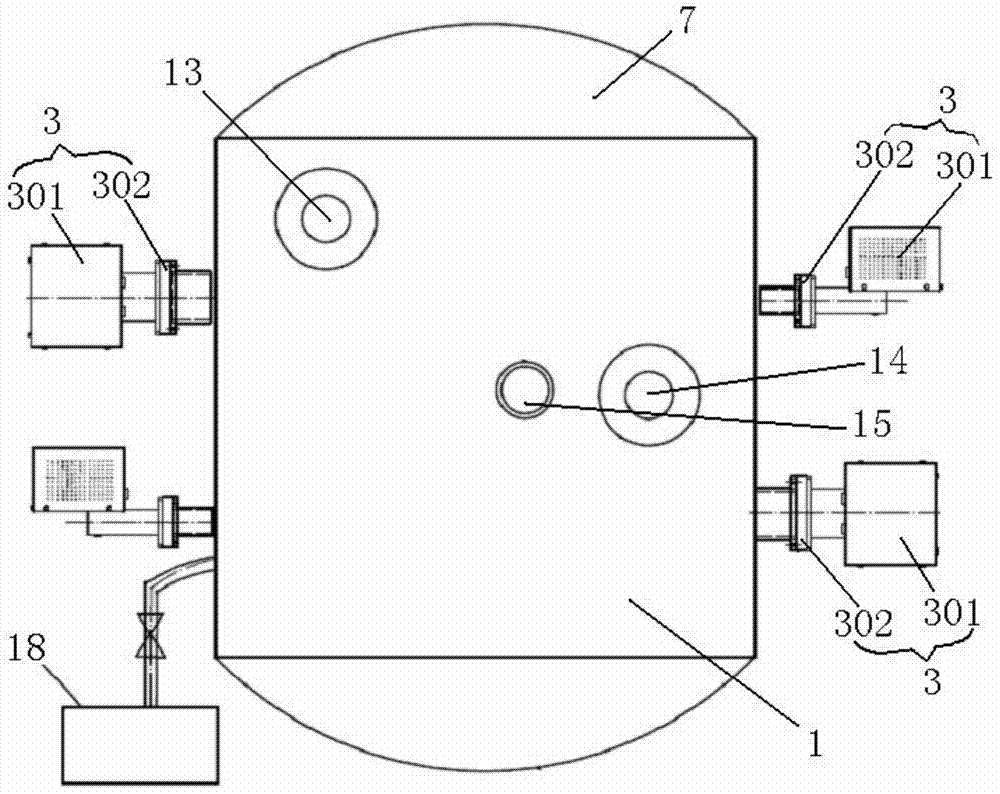

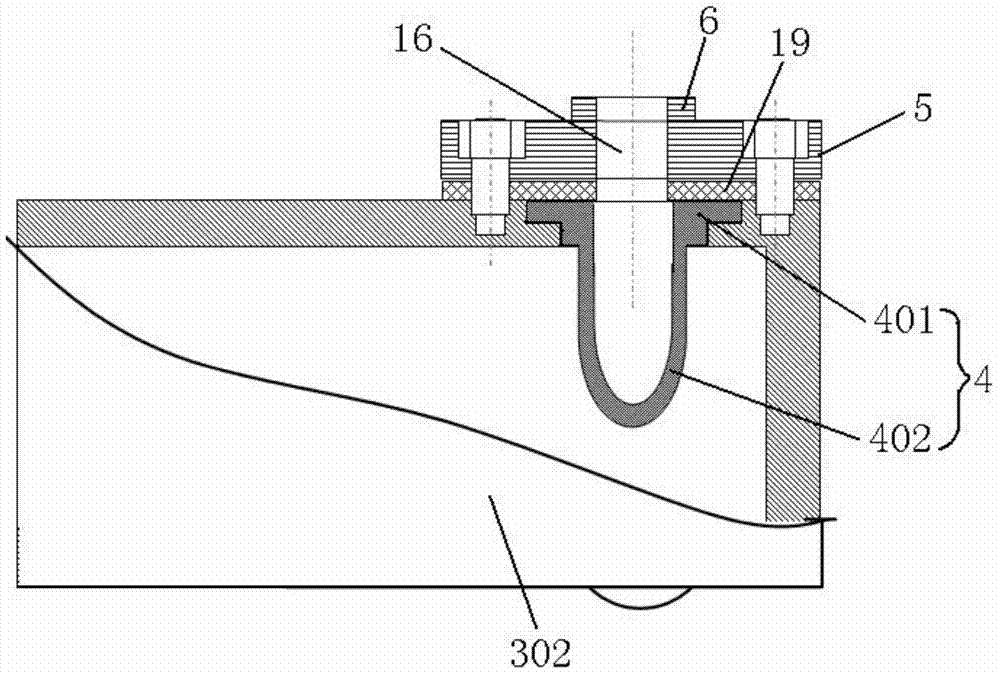

[0028] figure 1 It is one of the structural schematic diagrams of the microwave vacuum pressure sintering furnace in the preferred embodiment of the present invention; figure 2 It is the second structural diagram of the microwave vacuum pressure sintering furnace in the preferred embodiment of the present invention; image 3 is a schematic structural diagram of a microwave generating device in a preferred embodiment of the present invention; Figure 4 is a schematic structural diagram of a U-shaped flange in a preferred embodiment of the present invention; Figure 5 It is the third schematic diagram of the structure of the microwave vacuum pressure sintering furnace in the preferred embodiment of the present invention; Image 6 It is a structural schematic diagram o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractoriness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com