A kind of mixed acid resistant rubber roller for stainless steel production line and its manufacturing method

A manufacturing method and technology for rubber rollers, which are applied to rubber rollers resistant to mixed acid and electrolytic nitric acid corrosion and their manufacturing fields, can solve the problems of short service life, sticky surface of the roller, strong corrosion, etc., and achieve long service life, Avoid sticky roller surface, good resistance to mixed acid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

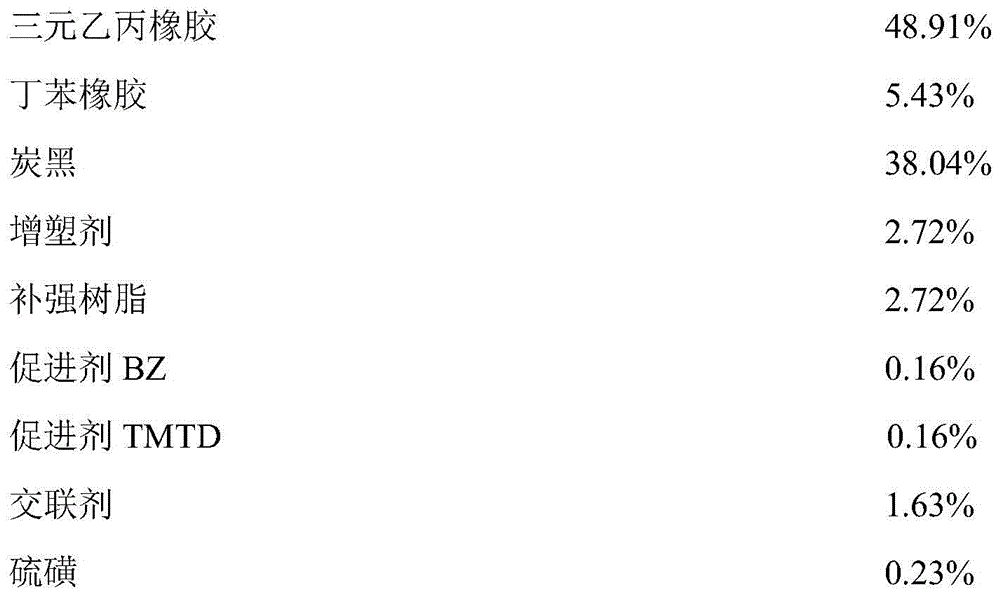

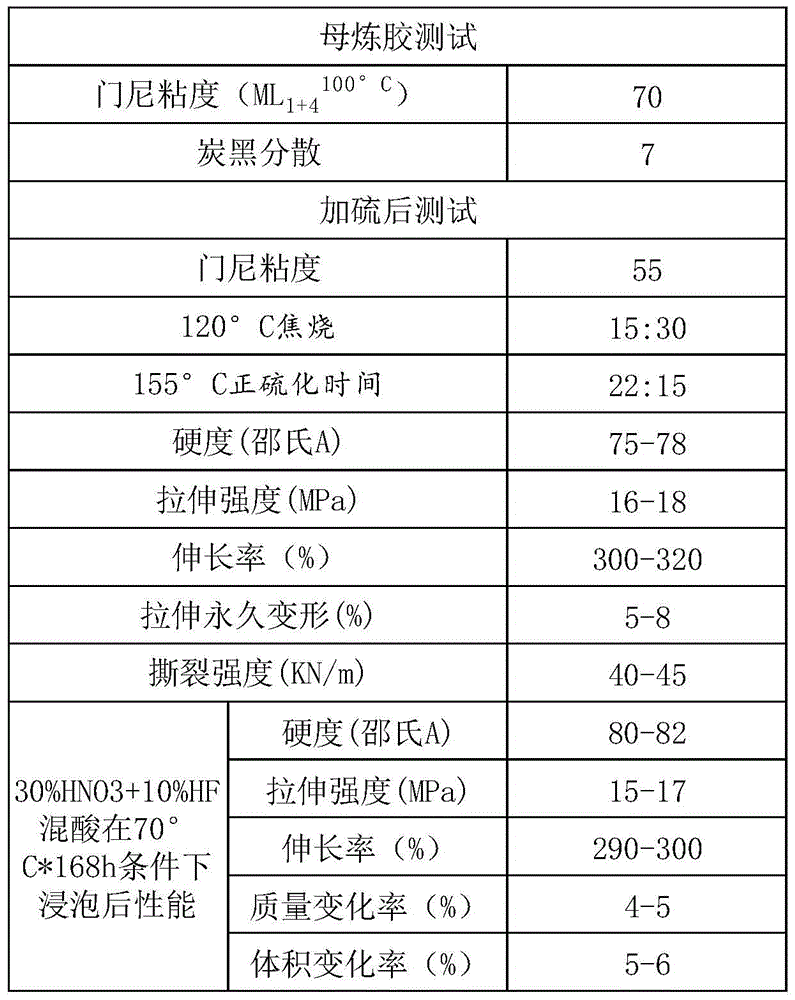

[0029] An acid-resistant rubber roller for a stainless steel production line in this embodiment has a specification of Φ500×Φ460×1700, and the rubber used is composed of the following components by weight percentage:

[0030]

[0031] According to the formula design requirements, EPDM rubber is Jihua 4045 EPDM rubber produced by Jihua Company, styrene-butadiene rubber is 1502 styrene-butadiene rubber produced by Qilu Petrochemical Company, and carbon black is N550 quick-extrusion carbon black produced by Cabot , the plasticizer is naphthenic rubber oil produced by Shanghai Luobo Lubricant Co., Ltd., the reinforcing resin is oligoester 12-1 produced by Xi'an Organic Chemical Factory, and the crosslinking agent is organic peroxide produced by Gaoqiao Petrochemical DCP, other materials are conventional commercially available products. The present invention improves the mixed-acid resistance of one type of rubber used alone through the combined use of 4045 ethylene propylene ru...

Embodiment 2

[0041] An acid-resistant rubber roller for a stainless steel production line in this example has a specification of Φ700×Φ660×1700, and the rubber used is composed of the following components by weight percentage:

[0042]

[0043]

[0044] According to the formula design requirements, EPDM rubber is Jihua 4045 EPDM rubber produced by Jihua Company, styrene-butadiene rubber is 1502 styrene-butadiene rubber produced by Qilu Petrochemical Company, and carbon black is N550 quick-extrusion carbon black produced by Cabot , the plasticizer is naphthenic rubber oil produced by Shanghai Luobo Lubricant Co., Ltd., the reinforcing resin is oligoester produced by Xi’an Organic Chemical Factory, the crosslinking agent is organic peroxide DCP produced by Gaoqiao Petrochemical, and others Materials are conventional commercially available products.

[0045] A kind of anti-mixing acid rubber roller for stainless steel production line using above-mentioned components and percentage conte...

Embodiment 3

[0051] A stainless steel production line in this embodiment uses acid-resistant rubber rollers, the specification is Φ1200×Φ1160×1700, and the rubber used is composed of the following components by weight percentage:

[0052]

[0053] According to the formula design requirements, EPDM rubber is Jihua 4045 EPDM rubber produced by Jihua Company, styrene-butadiene rubber is 1502 styrene-butadiene rubber produced by Qilu Petrochemical Company, and carbon black is N550 quick-extrusion carbon black produced by Cabot , the plasticizer is naphthenic rubber oil produced by Shanghai Luobo Lubricant Co., Ltd., the reinforcing resin is oligoester produced by Xi’an Organic Chemical Factory, the crosslinking agent is organic peroxide DCP produced by Gaoqiao Petrochemical, and others Materials are conventional commercially available products.

[0054] A kind of anti-mixing acid rubber roller for stainless steel production line using above-mentioned components and percentage content thereo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com