Metallocene polypropylene subchloride synthetic process by using water phase suspension method

A technology of metallocene polypropylene and chlorinated metallocene, applied in the field of low-chlorinated metallocene polypropylene synthesis process by aqueous phase suspension method, can solve the problem of inability to break the crystallinity of polypropylene and the inability to produce soluble chlorinated polypropylene products , affect product quality and other issues, to achieve the effect of solving low-temperature gel phenomenon, solving the problem of chlorination uniformity, and improving chlorination uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

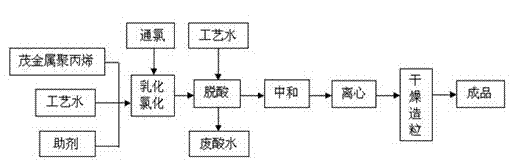

Image

Examples

Embodiment 1

[0023] 1. Select raw materials: 80 liters of process water, 5Kg of metallocene polypropylene powder or granules, 50g of dispersant, 50g of emulsifier, 3g of initiator, and 5Kg of liquid chlorine.

[0024] 2. Use a 100-liter enamel reactor for emulsification and chlorination reaction

[0025] (1) Add process water into the reaction kettle, start stirring, add dispersant, emulsifier and metallocene polypropylene powder or granules in turn, open the steam valve of the reaction kettle to emulsify at room temperature, emulsify for 30 minutes, when the temperature in the kettle rises to 85~ At 90°C, add an initiator to the reaction kettle, close the reaction kettle, start to introduce chlorine gas, control the temperature of the kettle at 90-95°C, and chlorinate the polypropylene in the aqueous phase suspension. As the amount of chlorine increases, the temperature of the material in the reactor also increases. Controlling the reaction temperature is the key factor for the smooth ...

Embodiment 2

[0030] 1. Select raw materials: 80 liters of process water, 9Kg of metallocene polypropylene powder or granules, 2000g of dispersant, 1000g of emulsifier, 10g of initiator, and 10.8Kg of liquid chlorine.

[0031] 2. Use a 100-liter enamel reactor for emulsification and chlorination reaction

[0032] (1) Add process water into the reaction kettle, start stirring, add dispersant, emulsifier and metallocene polypropylene powder or granules in turn, open the steam valve of the reaction kettle to emulsify at room temperature, emulsify for 30 minutes, when the temperature in the kettle rises to 85~ At 90°C, add an initiator to the reaction kettle, close the reaction kettle, start to introduce chlorine gas, control the temperature of the kettle at 90-95°C, and chlorinate the polypropylene in the aqueous phase suspension. As the amount of chlorine increases, the temperature of the material in the reactor also increases. Controlling the reaction temperature is the key factor for the...

Embodiment 3

[0037] 1. Select raw materials: 80 liters of process water, 10Kg of metallocene polypropylene powder or granules, 4500g of dispersant, 3000g of emulsifier, 40g of initiator, and 14Kg of liquid chlorine.

[0038] 2. Use a 100-liter enamel reactor for emulsification and chlorination reaction

[0039](1) Add process water into the reaction kettle, start stirring, add dispersant, emulsifier and metallocene polypropylene powder or granules in turn, open the steam valve of the reaction kettle to emulsify at room temperature, emulsify for 30 minutes, when the temperature in the kettle rises to 85~ At 90°C, add an initiator to the reaction kettle, close the reaction kettle, start to introduce chlorine gas, control the temperature of the kettle at 90-95°C, and chlorinate the polypropylene in the aqueous phase suspension. As the amount of chlorine increases, the temperature of the material in the reactor also increases. Controlling the reaction temperature is the key factor for the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com