A kind of loaded type diesel oil hydrogenation treatment catalyst and its application

A hydrotreating, load-type technology, applied in the direction of physical/chemical process catalysts, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of not being able to reduce the content of the three substances at the same time, high catalyst cost, low catalytic efficiency, etc., to improve Improved heat resistance, dearomatization effect, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Preparation method of a supported diesel hydrotreating catalyst

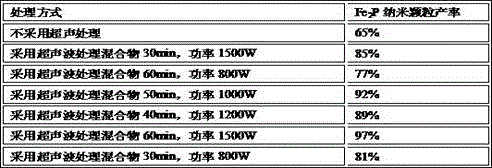

[0033] (1) Nano Fe 2 The preparation steps of P are as follows:

[0034] ① Hydrothermal treatment of red phosphorus: Take an appropriate amount of lumpy red phosphorus, put it in a mortar, add distilled water to immerse the red phosphorus, grind for 10 minutes, turn the lumpy red phosphorus into powder, and mix it with distilled water to form a uniform and fine paste. Transfer the pasty red phosphorus to the PTFE lining, and add distilled water to make the filling rate of the lining reach 80%; cover the inner lining, put it vertically into the autoclave, and put it into the gasket , tighten the seal, then put the reaction kettle into a constant temperature oven, heat up to 180°C, keep it warm for 24 hours, cool down to room temperature naturally, take out the tetrafluoroethylene liner carefully, transfer the contents into a beaker, and obtain nano-scale The suspension of red phosphorus powder ...

Embodiment 2

[0039] Example 2 Preparation method of a supported diesel hydrotreating catalyst

[0040] (1) Nano Fe 2 The preparation steps of P are as follows:

[0041] ① Hydrothermal treatment of red phosphorus: Take out an appropriate amount of lumpy red phosphorus, put it in a mortar, add distilled water to immerse the red phosphorus, and grind for 30 minutes to turn the lumpy red phosphorus into powder, and mix it with distilled water to form a uniform and fine paste. Transfer the pasty red phosphorus to the PTFE lining, and add distilled water to make the filling rate of the lining reach 80%; cover the inner lining, put it vertically into the autoclave, and put it into the gasket , tighten the seal, then put the reaction kettle into a constant temperature oven, heat up to 220°C, keep warm for 20 hours, cool down to room temperature naturally, take out the tetrafluoroethylene liner carefully, transfer the contents into a beaker, and obtain nano-scale The suspension of red phosphorus ...

Embodiment 3

[0046] Example 3 Preparation method of a supported diesel hydrotreating catalyst

[0047] (1) Nano Fe 2 The preparation steps of P are as follows:

[0048] ① Hydrothermal treatment of red phosphorus: Take out an appropriate amount of lumpy red phosphorus, put it in a mortar, add distilled water to immerse the red phosphorus, grind for 15 minutes, turn the lumpy red phosphorus into powder, and mix it with distilled water to form a uniform and delicate paste. Transfer the pasty red phosphorus to the PTFE lining, and add distilled water to make the filling rate of the lining reach 80%; cover the inner lining, put it vertically into the autoclave, and put it into the gasket , tighten the seal, then put the reaction kettle into a constant temperature oven, heat up to 200°C, keep warm for 22 hours, cool down to room temperature naturally, take out the tetrafluoroethylene liner carefully, transfer the contents into a beaker, and obtain nano-scale The suspension of red phosphorus po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com