A kind of preparation method of γ-alumina powder material coated with silicon dioxide nanometer layer

A technology of alumina powder and silica, used in chemical instruments and methods, catalyst carriers, catalysts for physical/chemical processes, etc., can solve the problem of time-consuming and labor-intensive treatment of liquid waste, reduction of material specific surface area, uneven dispersion of additives, etc. problem, to achieve the effects of low cost, improved thermal stability, and simple method operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

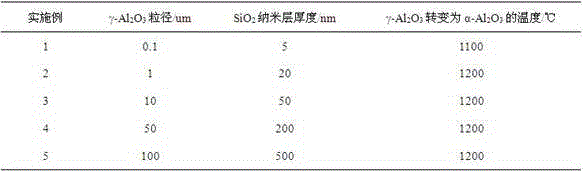

Examples

Embodiment 1

[0022] The preparation method of the gamma-alumina powder material coated with silica nano-layer provided by the present invention, the preparation steps are as follows:

[0023] (1) Use γ-Al 2 o 3 The purity of the powder is 95%, the particle size is 100nm, and the γ-Al 2 o 3 After the powder is dried, it is sieved, the drying temperature is 150°C, and it is dried for 5 hours. The size of the sieve hole is 200 mesh, and it is sieved three times; 2 o 3 The powder is placed in the chemical vapor deposition reaction chamber, vacuumed to 5Pa, and preheated to 400°C;

[0024] (2) Using ethyl orthosilicate as raw material, heat until the temperature reaches 80°C, and the reaction chamber starts to rotate at a rotation rate of 30r / min;

[0025] (3) Feed raw materials, argon and oxygen into the reaction chamber, wherein the flow rate of argon gas is 30sccm, and the flow rate of oxygen gas is 20sccm, then adjust the pressure in the reaction chamber, the pressure is 500Pa, and the...

Embodiment 2

[0029] The preparation method of the gamma-alumina powder material coated with silica nano-layer provided by the present invention, the preparation steps are as follows:

[0030] (1) Use γ-Al 2 o 3 The purity of the powder is 96%, the particle size is 1 μm, and the γ-Al 2 o 3 After the powder is dried, it is sieved, the drying temperature is 150°C, and it is dried for 7 hours. The size of the sieve hole is 200 mesh, and it is sieved three times; 2 o 3 The powder is placed in the chemical vapor deposition reaction chamber, vacuumed to 10Pa, and preheated to 500°C;

[0031] (2) Using tetraethyl orthosilicate as raw material, heat until the temperature reaches 90°C, and the reaction chamber starts to rotate at a rotation rate of 45r / min;

[0032] (3) Pass raw materials, argon and oxygen into the reaction chamber, wherein the flow rate of argon gas is 40 sccm, and the flow rate of oxygen gas is 10 sccm, then adjust the pressure in the reaction chamber, the pressure is 500 Pa,...

Embodiment 3

[0036] The preparation method of the gamma-alumina powder material coated with silica nano-layer provided by the present invention, the preparation steps are as follows:

[0037] (1) Use γ-Al 2 o 3 The purity of the powder is 98%, the particle size is 10 μm, and the γ-Al 2 o 3 After the powder is dried, it is sieved, the drying temperature is 150°C, and it is dried for 8 hours. The size of the sieve hole is 100 mesh, and it is sieved three times; 2 o 3 The powder is placed in the chemical vapor deposition reaction chamber, vacuumed to 15Pa, and preheated to 500°C;

[0038] (2) Using tetraethyl orthosilicate as raw material, heat until the temperature reaches 90°C, and the reaction chamber starts to rotate at a rotation rate of 60r / min;

[0039] (3) Pass raw materials, argon and oxygen into the reaction chamber, wherein the flow rate of argon gas is 40 sccm, and the flow rate of oxygen gas is 10 sccm, then adjust the pressure in the reaction chamber, the pressure is 800 Pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com