Traditional Chinese medicine tea with effect of dispelling effects of alcohol and preparation method of traditional Chinese medicine tea

A technology of traditional Chinese medicine tea and efficacy, applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, tea substitutes, etc., can solve the problems of low treatment efficiency, poor treatment effect, and inability to quickly and effectively solve symptoms, etc. The effect of wine is good, the effect of good curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

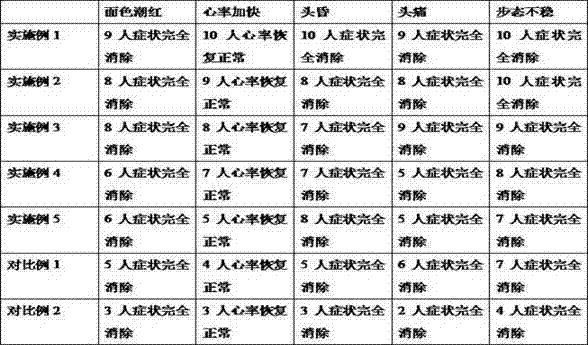

Examples

Embodiment 1

[0054] (1) Grind the kudzu root block into powder with a pulverizer, crush it to 300 mesh, and then dry the kudzu root powder, the drying method is vacuum drying, the temperature is 50 ° C, and the vacuum degree is 5 Pa;

[0055] (2) Freeze-dry salvia miltiorrhiza and chrysanthemum at -15°C for 12 hours, freeze-dry and grind for later use;

[0056] (3) Grind the dried mung beans into mung bean powder with a mesh number of 300, and set aside;

[0057] (4) Separating the red bayberry meat from the red bayberry core of fresh red bayberry, beating the red bayberry meat, crushing the red bayberry core after crushing, mixing the red bayberry pulp and bayberry river powder evenly, and vacuum drying after mixing evenly, the vacuum drying temperature is 60 ° C, The vacuum degree is 5Pa, which is bayberry powder;

[0058] (5) Mix the three raw materials of Jintiesuo, Gentiana chinensis and Vasong, and then vacuum-dry them. The vacuum drying temperature is 60°C, and the vacuum degree is...

Embodiment 2

[0061] (1) Grind the kudzu root block into powder with a pulverizer, crush it to 300 mesh, and then dry the kudzu root powder, the drying method is vacuum drying, the temperature is 50°C, and the vacuum degree is 500Pa;

[0062] (2) Freeze-dry salvia miltiorrhiza and chrysanthemum at -15°C for 12 hours, freeze-dry and grind for later use;

[0063] (3) Grind the dried mung beans into mung bean powder with a mesh number of 300, and set aside;

[0064](4) Separating the red bayberry meat from the red bayberry core of fresh red bayberry, beating the red bayberry meat, crushing the red bayberry core after crushing, mixing the red bayberry pulp and bayberry river powder evenly, and vacuum drying after mixing evenly, the vacuum drying temperature is 60 ° C, Vacuum degree is 50Pa, it is red bayberry powder;

[0065] (5) Mix the three raw materials of Jintiesuo, Gentiana chinensis and Vasong, and then carry out vacuum drying. The vacuum drying temperature is 60°C, the vacuum degree is...

Embodiment 3

[0068] (1) Grind the kudzu root block into powder with a pulverizer, crush it to 300 mesh, and then dry the kudzu root powder, the drying method is vacuum drying, the temperature is 50 ° C, and the vacuum degree is 100 Pa;

[0069] (2) Freeze-dry salvia miltiorrhiza and chrysanthemum at -15°C for 12 hours, freeze-dry and grind for later use;

[0070] (3) Grind the dried mung beans into mung bean powder with a mesh number of 300, and set aside;

[0071] (4) Separating the red bayberry meat from the red bayberry core of fresh red bayberry, beating the red bayberry meat, crushing the red bayberry core after crushing, mixing the red bayberry pulp and bayberry river powder evenly, and vacuum drying after mixing evenly, the vacuum drying temperature is 60 ° C, Vacuum degree is 500Pa, it is red bayberry powder;

[0072] (5) Mix the three raw materials of Jintiesuo, Gentiana chinensis and Vasong, and then carry out vacuum drying. The vacuum drying temperature is 60°C, the vacuum degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com