Bamboo charcoal fiber fabric for home textiles

A bamboo charcoal fiber and fabric technology, applied in the direction of fiber chemical characteristics, textile material processing, cellulose/protein conjugated artificial filament, etc., can solve the problems of fiber material softness and antibacterial properties to be improved, and achieve jacquard quality Stable, high-grade, good hand feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

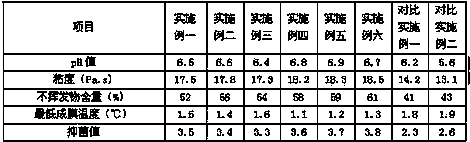

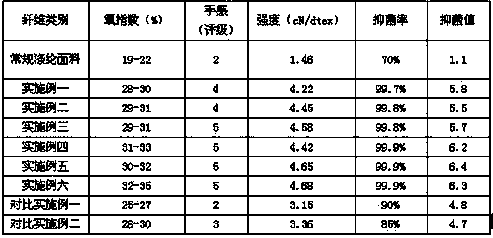

Examples

Embodiment 1

[0053] Preparation of nano silver:

[0054] A. Add sodium dodecylsulfonate solution, water-based polyacrylate and hydrazine hydrate solution to silver nitrate aqueous solution to obtain a mixed solution. The molar ratio of sodium dodecylsulfonate to silver nitrate is 4:1; The molar ratio of acrylate to silver nitrate is 0.4:1; the molar ratio of hydrazine hydrate to silver nitrate is 0.2:1;

[0055] B. Add dicyclohexyl-18-crown-6 and sodium metaphosphate to the mixture, the molar ratio of dicyclohexyl-18-crown-6 to silver nitrate is 3:1; sodium metaphosphate and nitric acid The molar ratio of silver is 0.8:1, and the pH value is controlled to be 8-9 to obtain nano silver.

[0056]

[0057] The composition ratio of the viscose liquid used for bamboo charcoal fiber fabrics:

[0058] 25 parts of phthalic anhydride, 7 parts of furfuryl alcohol extracted from corncob residue, 10 parts of triethylene glycol, 15 parts of glutaric acid, 8 parts of butanetriol, 5 parts of zinc oxide...

Embodiment 2

[0085] Preparation of nano silver:

[0086] A. Add sodium dodecyl sulfonate solution, water-based polyacrylate and hydrazine hydrate solution to silver nitrate aqueous solution to obtain a mixed solution. The molar ratio of sodium dodecyl sulfonate to silver nitrate is 6:1; The molar ratio of acrylate to silver nitrate is 0.6:1; the molar ratio of hydrazine hydrate to silver nitrate is 0.3:1;

[0087] B. Add dicyclohexyl-18-crown-6 and sodium metaphosphate to the mixture, the molar ratio of dicyclohexyl-18-crown-6 to silver nitrate is 5:1; sodium metaphosphate and nitric acid The molar ratio of silver is 1.3:1, and the pH value is controlled to be 8-9 to obtain nano silver.

[0088]

[0089] The composition ratio of the viscose liquid used for bamboo charcoal fiber fabrics:

[0090] 35 parts of phthalic anhydride, 11 parts of furfuryl alcohol extracted from oat or wheat bran, 12 parts of triethylene glycol, 18 parts of glutaric acid, 10 parts of butanetriol, 7 parts of zinc...

Embodiment 3

[0115] Preparation of nano silver:

[0116] A. Add sodium dodecyl sulfonate solution, water-based polyacrylate and hydrazine hydrate solution to silver nitrate aqueous solution to obtain a mixed solution. The molar ratio of sodium dodecyl sulfonate to silver nitrate is 5:1; The molar ratio of acrylate to silver nitrate is 0.5:1; the molar ratio of hydrazine hydrate to silver nitrate is 0.25:1;

[0117] B. Add dicyclohexyl-18-crown-6 and sodium metaphosphate to the mixture, the molar ratio of dicyclohexyl-18-crown-6 to silver nitrate is 4:1; sodium metaphosphate and nitric acid The molar ratio of silver is 1:1, and the pH value is controlled to be 8-9 to obtain nano silver.

[0118]

[0119] The composition ratio of the viscose liquid used for bamboo charcoal fiber fabrics:

[0120] 30 parts of phthalic anhydride, 7-11 parts of furfuryl alcohol extracted from bamboo sawdust, 11 parts of triethylene glycol, 16 parts of glutaric acid, 9 parts of butanetriol, 6 parts of zinc ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com