A process for preparing aluminum alloy semi-solid blanks by combining electromagnetic forming and secondary remelting

An electromagnetic forming and secondary remelting technology, applied in the field of metal semi-solid blank preparation, can solve the problems of low deformation efficiency, low melt conductivity, long stirring time, etc., to improve the forming quality, simplify the process flow, and improve the deformation quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] The aluminum alloy material selected in this embodiment is A356.2, the secondary remelting temperature is 580° C., and the holding time is 10 minutes.

[0029] A process for preparing an aluminum alloy semi-solid billet by combining electromagnetic forming and secondary remelting, comprising the following steps:

[0030] 1) Material selection: choose aluminum alloy bar 1, where the material of aluminum alloy bar 1 is A356.2;

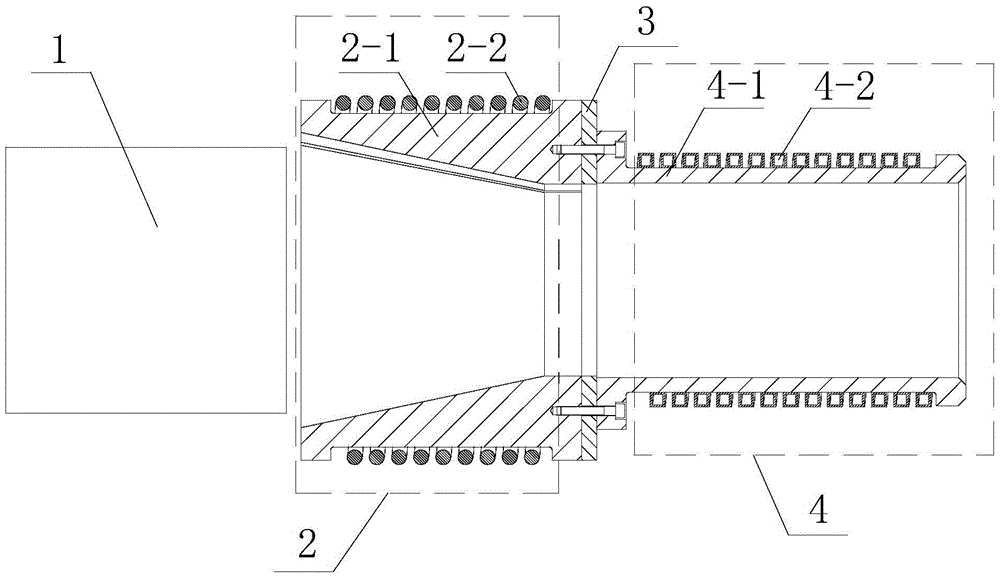

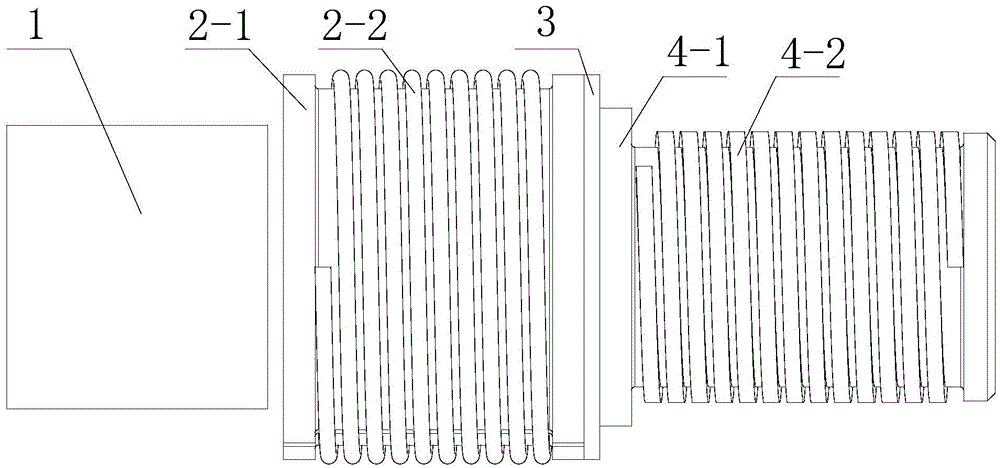

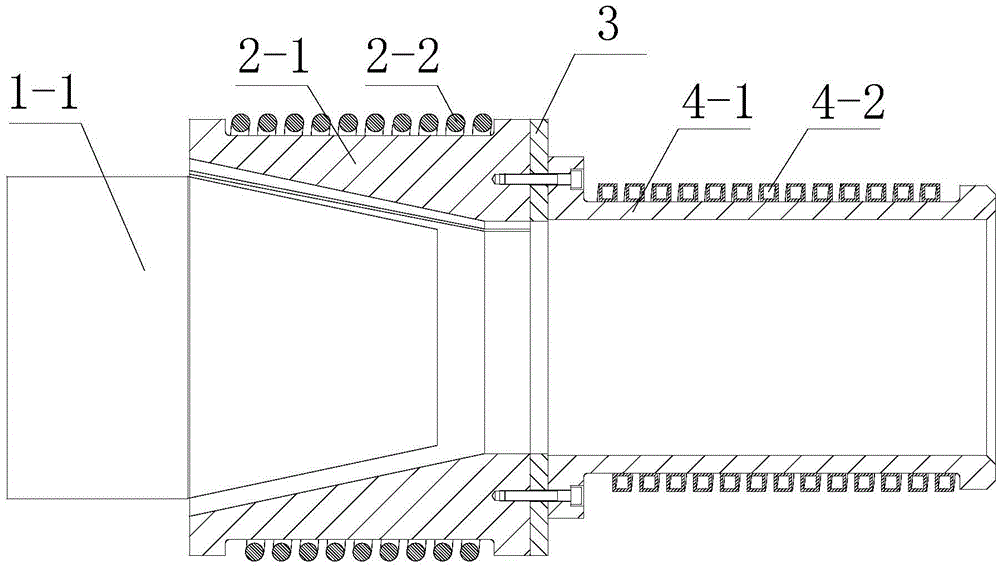

[0031] 2) Electromagnetic forming: refer to figure 1 and figure 2 , using the electromagnetic forming device 2 to plastically deform the aluminum alloy bar 1 and make it produce plastic strain, specifically:

[0032] 2.1) Reference image 3 , open the electromagnetic forming device 2 and gradually push the aluminum alloy bar 1 horizontally to move to the inside of the electromagnetic forming device 2, so that the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com