Preparation process for improving forming ability of Fe-base amorphous alloys

An iron-based amorphous alloy and preparation process technology, which can be used in manufacturing tools, casting and molding equipment, metal processing equipment, etc. The effect of weak forming ability of iron-based amorphous alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

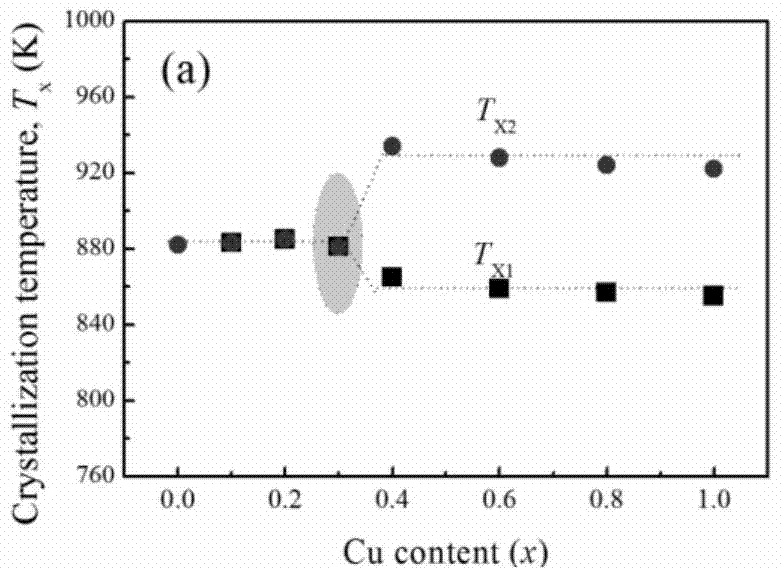

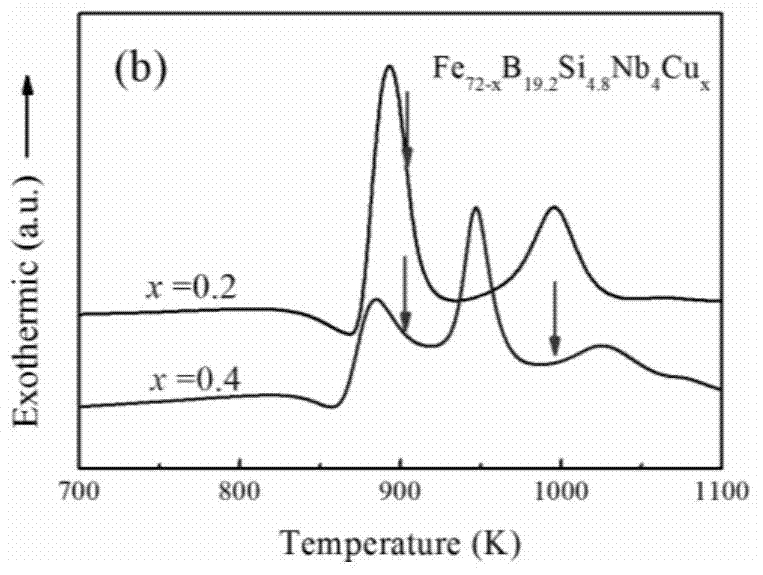

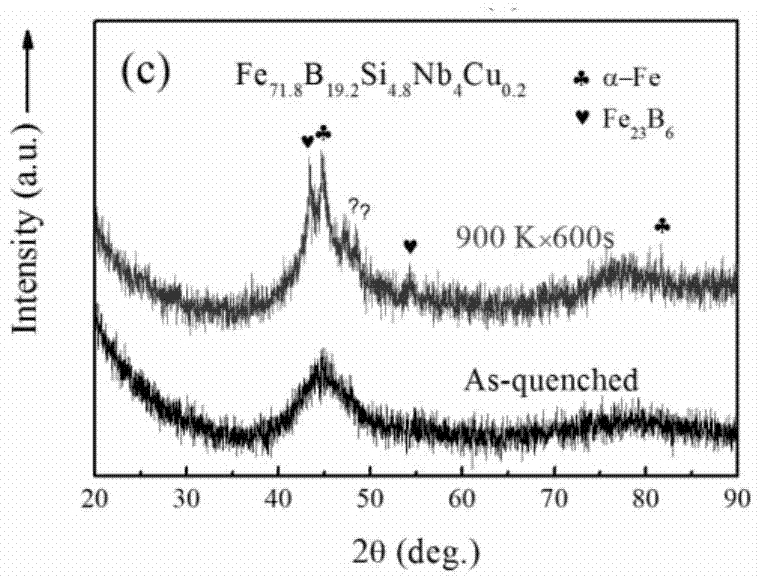

[0032] Example 1: According to Fe 72-x B 19.2 Si 4.8 Nb 4 Cu x (x=0, 0.1, 0.2, 0.3, 0.4, 0.6, 0.8, 1.0) The nominal composition of the alloy converts the atomic percentages of different types of elements in the alloy into mass percentages, and weighs high-purity raw materials in proportion: Fe (99.99%), Cu (99.99%), B (99.7%), Si (99.99%) and Nb (99.99%) are available for use.

[0033] Mix the raw materials according to the above composition ratio and place them in the water-cooled copper crucible of the electric arc melting furnace, and evacuate to less than 5×10 -5 After Pa is filled with argon gas to a pressure of 600mbar, the melting is continued for 5 minutes after melting. After the molten alloy is cooled to solidification, it is turned over and smelted again, and the smelting is repeated 4 times to obtain a master alloy ingot with uniform composition.

[0034] The ingot cooled to room temperature is taken out from the electric arc melting furnace, the surface impurit...

Embodiment 2

[0040] Embodiment 2: alloy composition is Fe 84-x Nb 2 B 14 Cu x (x=0, 0.5, 1.0, 1.5). Iron-based amorphous alloy strips were prepared only by single-roll rapid quenching. From Figure 4 It can be seen that when the copper content is 0.5 atomic percent, the amorphous-forming ability of the alloy is effectively improved. Others are the same as in Example 1.

Embodiment 3

[0041] Embodiment 3: The technological process of the following various iron-based amorphous alloy systems is the same as that of the embodiment.

[0042] Table 1 lists seven iron-based amorphous alloy systems and their example alloy compositions. As can be seen from Table 1, the formation ability of the amorphous alloy of the example alloy composition in these seven kinds of iron-based amorphous alloy systems after adding trace copper elements has all been improved, showing that the method of the present invention is adopted in the following seven kinds of alloy systems It is feasible to improve the forming ability of amorphous alloy. Especially for increasing high iron content such as Fe 84 Nb 2 B 14 , Fe 86 B 7 C 7 , Fe 84 P 10 C 6 The ability of amorphous alloys such as alloys to form amorphous has the advantages that other amorphous alloys are difficult to replace.

[0043] Table 1 Effect of copper addition on the forming ability of several typical iron-based am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com