Flunixin meglumine coated granule and preparation method thereof

A technology of flunixin meglumine and coated granules, which is applied in the field of flunixin meglumine coated granules and its preparation, which can solve the problems of irritating the respiratory tract and eyes, poor compliance, and discomfort of workers, and achieve stress Reduced, increased feed intake, good curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

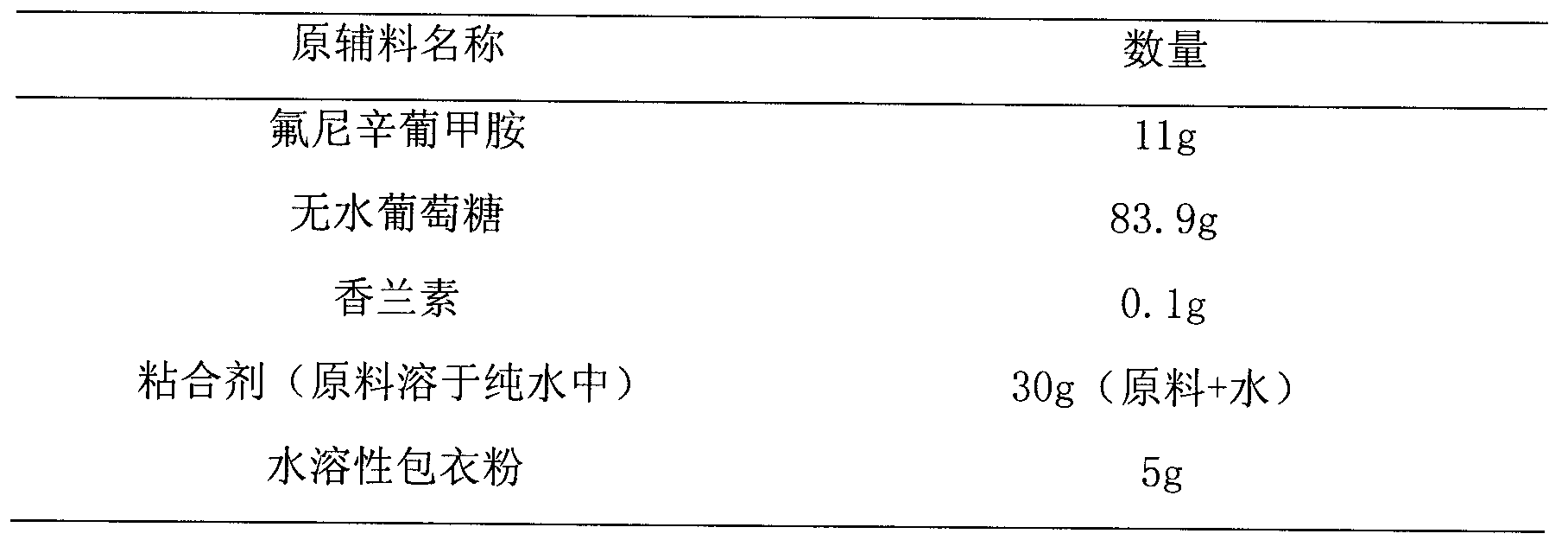

[0032] Formation

[0033]

[0034] Preparation Process

[0035] 1) Weighing: Weigh the prescribed amount of anhydrous glucose and vanillin into a one-step granulator for fluidized mixing:

[0036] 2) Prepare the drug solution as an adhesive: add the prescribed amount of flunixin meglumine into 21 g of water, and heat to dissolve if necessary;

[0037] 3) Granulation: spray the drug solution into the fluidized material for granulation;

[0038] 4) Coating: first prepare a coating solution, add 5 g of coating powder to 20 g of water, stir and dissolve, and set aside. After the granules are formed, they are dried and then sprayed into the coating solution.

[0039] 5) After the coating is completed, it is dried and ready to be obtained.

Embodiment 2

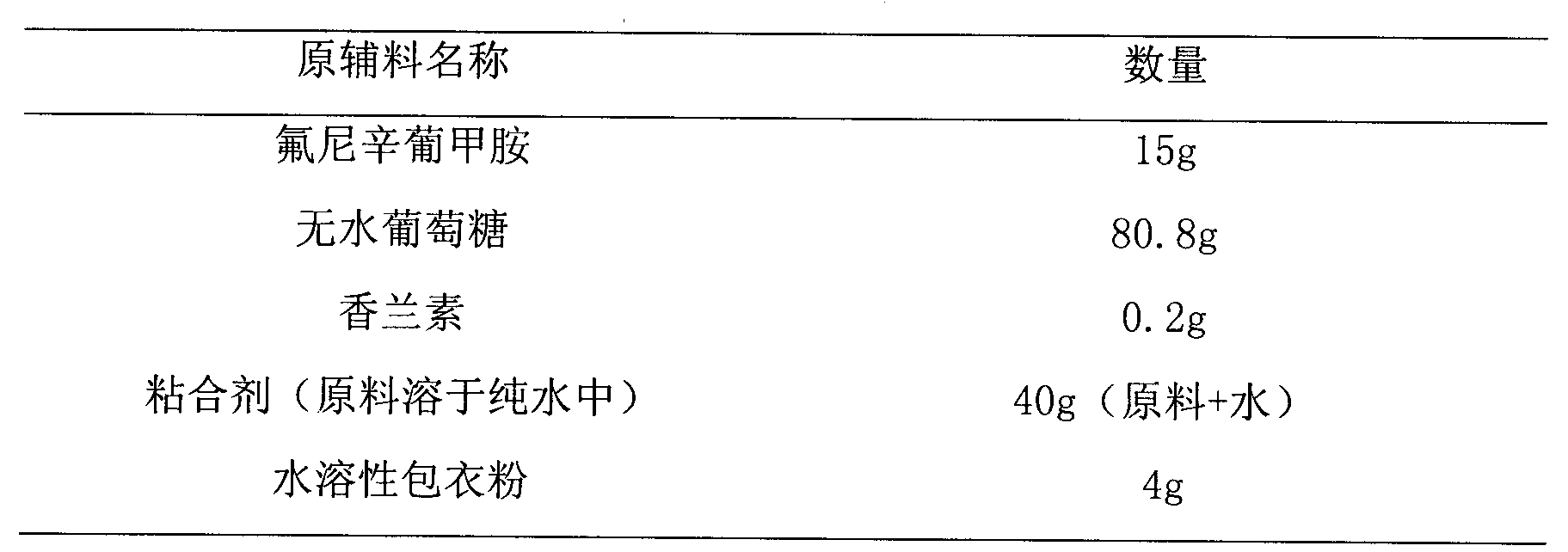

[0041] Formation

[0042]

[0043] Preparation Process

[0044] Same as Example 1, except that the prescription quantities of raw materials, anhydrous glucose and coating powder are different.

Embodiment 3

[0046] Party:

[0047]

[0048] Preparation Process:

[0049] Same as Example 1, except that the prescription quantities of raw materials, anhydrous glucose, vanillin and coating powder are different.

[0050] The flunixin meglumine coated granule of embodiment 1 carries out the accelerated test in the stability test

[0051] Stability test method: Prepare 3 batches of products (20130806, 20130807, 20130808) according to Example 1, place them under the condition of temperature 40 ℃ ± 2 ℃ and relative humidity 75% ± 5% for 6 months according to the commercially available packaging, and test During the 1st, 2nd, 3rd, and 6th months, samples were taken once respectively, and the properties, dissolution rate, and content of the key stability inspection items were tested. The results of the stability test are shown in Table 1.

[0052] Table 1 Stability test results of flunixin meglumine granules

[0053]

[0054] The clinical trial situation of the flunixin meglumine coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com