Method for preparing high-power and long-service-life lithium iron phosphate anode material

A technology of lithium iron phosphate and positive electrode materials, which is applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor rate performance, poor cycle performance, and low free radical polymer capacity of lithium iron phosphate, and achieve improved Rate performance, high charge storage density, and the effect of promoting the transfer of carbon layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

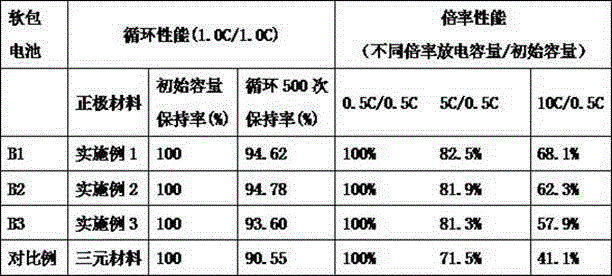

Embodiment 1

[0019] Embodiment 1: setting free radical monomer: conductive agent: dopant: oxidizing agent: solvent = (1-10g): (1-10g): (1-5ml): (1-20ml): 100ml.

[0020] 1. Preparation of free radical mixed solution: weigh 5g of s-trimethylaniline monomer and dissolve in 100ml of CHCl 3 In the solvent, after stirring evenly, add 5g of carbon nanotubes, 3ml of HCl dopant, and 10ml of 0.1mol / L FeCl 3 oxidizing agent, and the polymerization reaction occurs at a temperature of 80°C to prepare a free radical polymer composite solution;

[0021] 2. Weigh 10.3gLiH at the same time 2 PO 4 and 36.9gFe(NO3) 3 9H 2 O is dissolved in 200mL of N,N-dimethylformamide solvent, stirred to obtain a lithium iron phosphate precursor solution, and then dried to obtain a lithium iron phosphate precursor;

[0022] 3. Weigh 15g of sucrose and mix with 40g of lithium iron phosphate precursor evenly, and heat up to 800°C at a heating rate of 5.0°C / min, keep it warm in the air atmosphere for 3 hours, cool to 15...

Embodiment 2

[0024] 1. Preparation of free radical mixed solution: weigh 1g triarylamine monomer and dissolve in 100ml CHCl 4 In the solvent, after stirring evenly, add 1g graphene, 1mlHClO 4 Dopant, 1ml of 0.1mol / L FeCl 3 An oxidizing agent, which undergoes a polymerization reaction at a temperature of 25°C to prepare a free radical polymer composite solution;

[0025] 2. Weigh 10.3gLiH 2 PO 4 and 32.5gFeC 6 h 5 o 7 ·5H 2 O is dissolved in 200mL of N,N-dimethylformamide solvent, stirred to obtain a lithium iron phosphate precursor solution, and then dried to obtain a lithium iron phosphate precursor;

[0026] 3. Weigh 10g of sucrose and 10g of lithium iron phosphate precursor and mix evenly, heat up to 600°C at a heating rate of 3.0°C / min, keep warm in air atmosphere for 4 hours, cool to 100°C, and follow step 1 100 g of the free radical polymer complex solution was mixed evenly, and kept warm for 1 hour, and then naturally cooled to room temperature to obtain a lithium iron phosp...

Embodiment 3

[0028] 1. Preparation of free radical mixed solution: weigh 10g of s-trimethylaniline monomer and dissolve in 100ml of CHCl 4 In the solvent, after stirring evenly, add 10g nano-carbon fiber, 5ml HCl dopant, 20ml (0.1mol / L) FeCl 3 Oxidant, and the polymerization reaction occurs at a temperature of 100 ° C to prepare a free radical polymer composite solution;

[0029] 2. Weigh 10.3gLiH at the same time 2 PO 4 and 32.5gFeC 6 h 5 o 7 ·5H 2 O is dissolved in 200mL of N,N-dimethylformamide solvent, stirred to obtain a lithium iron phosphate precursor solution, and then dried to obtain a lithium iron phosphate precursor;

[0030] 3. Weigh 20g of sucrose and 50g of lithium iron phosphate precursor and mix evenly, and heat up to 900°C at a heating rate of 10.0°C / min, keep it in the air atmosphere for 1 hour, then cool to 200°C, and step 1 100 g of the free radical polymer composite solution was uniformly mixed, and kept warm for 6 hours, and then naturally cooled to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com