Method for producing polarizing plate

A manufacturing method and technology for polarizers, which can be applied to polarizers, instruments, optical elements, etc., can solve the problems of polarizer wrinkles, disappearance of film strength, and decrease in strength, and achieve improved adhesion, excellent adhesion, and improved adhesion. The effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

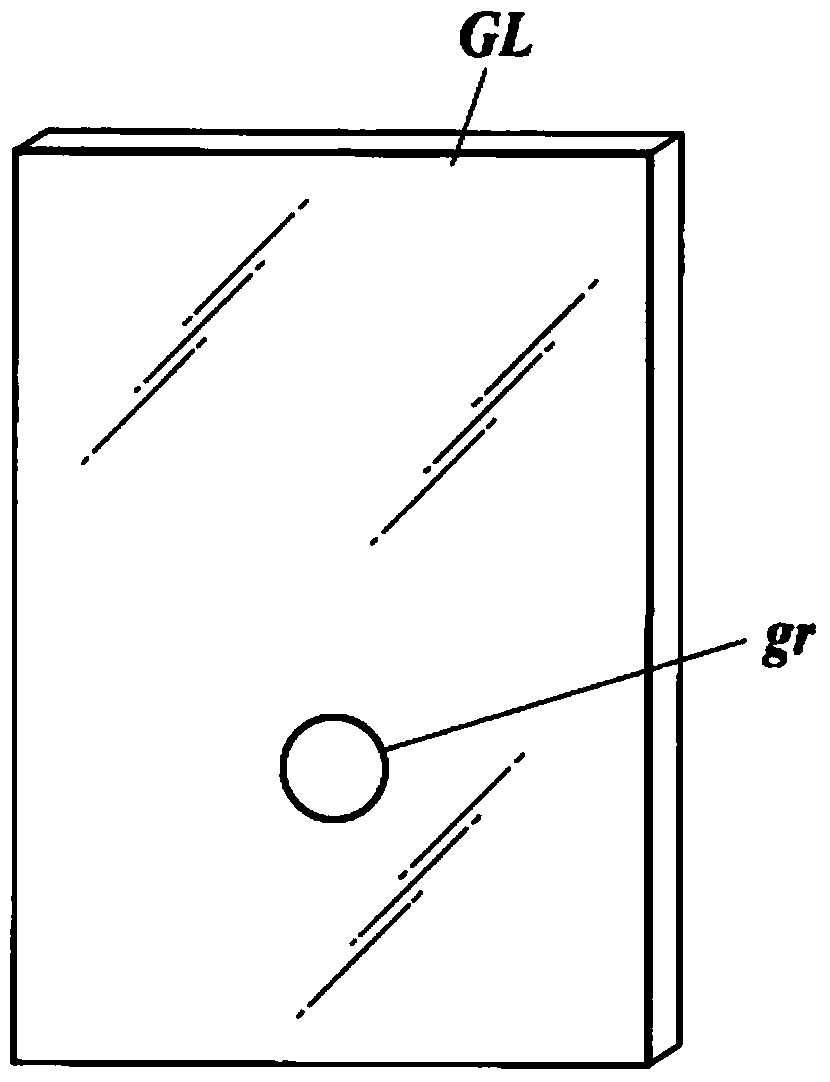

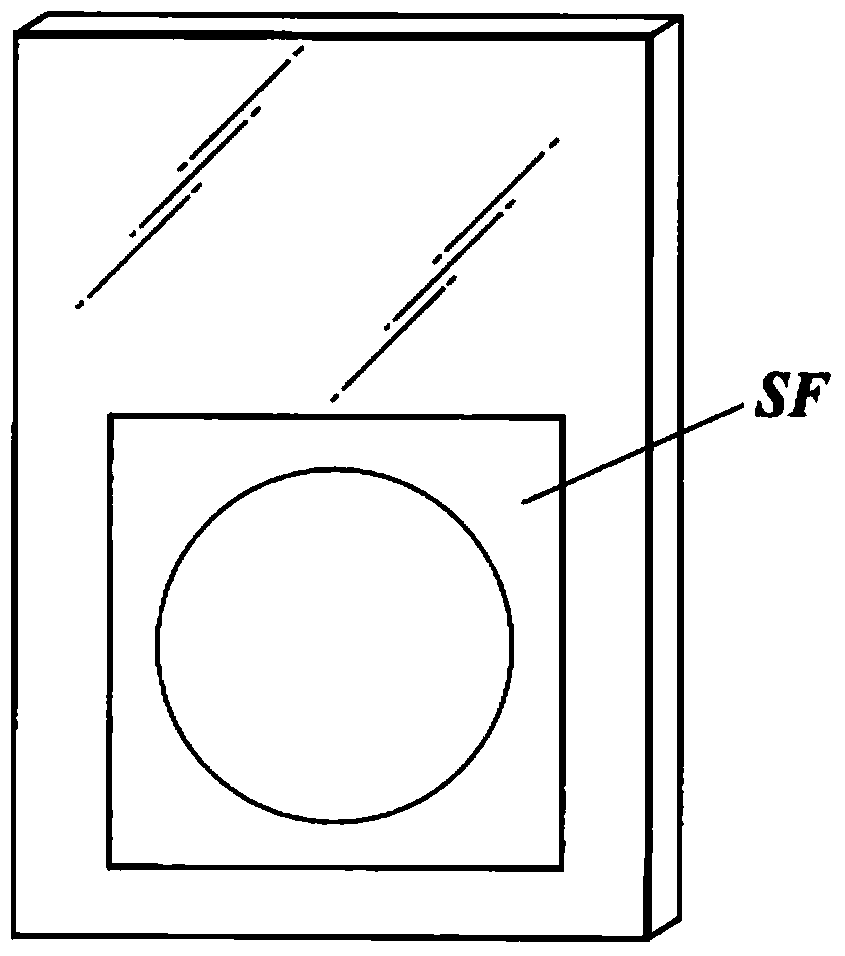

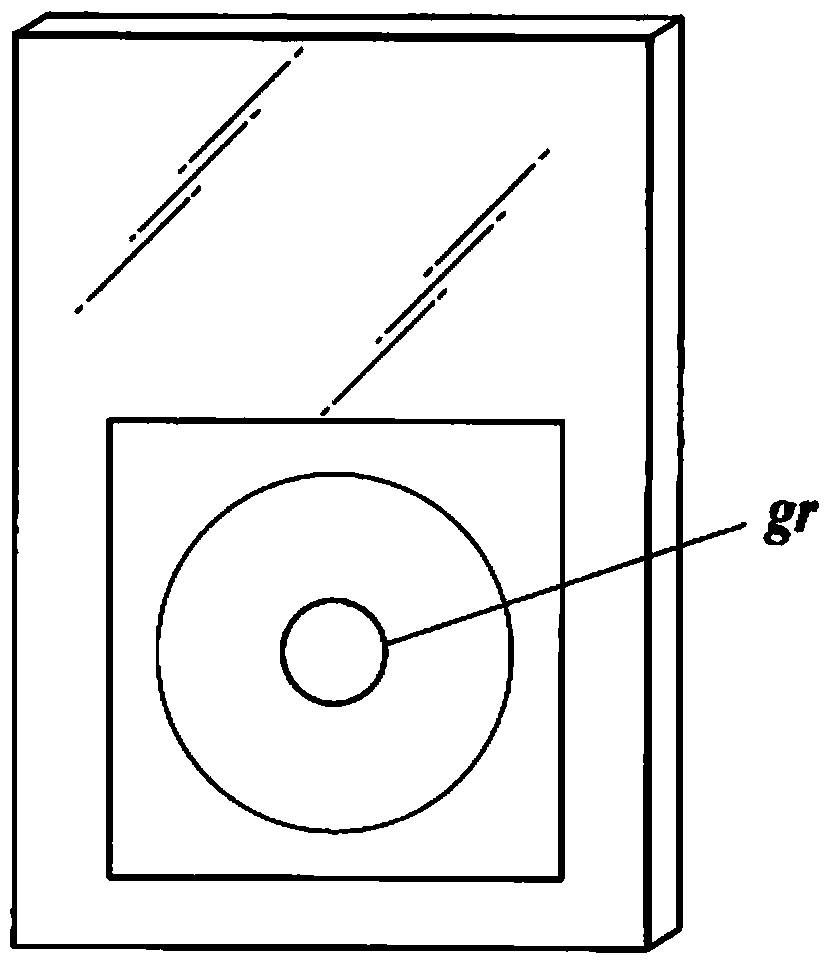

Image

Examples

Embodiment 1

[0405]

[0406]

[0407] (thermoplastic resin layer A)

[0408] The following film was prepared as the thermoplastic resin layer A.

[0409] As the crystalline ester thermoplastic resin, an amorphous polyethylene terephthalate film (A-PET) (Nobakuria manufactured by Mitsubishi Plastics Corporation, glass transition temperature 80° C.) having a film thickness of 200 μm and a length of 1000 m was used.

[0410] (hydrophilic polymer layer)

[0411] Polyvinyl alcohol powder as a hydrophilic polymer (manufactured by Japan VAM POVAL Co., Ltd., average polymerization degree 2500, saponification degree 99.0 mol% or more, trade name: JC-25) was dissolved in hot water at 95°C to prepare An aqueous solution of polyvinyl alcohol having a concentration of 8% by mass. The obtained polyvinyl alcohol aqueous solution was coated on the above-mentioned thermoplastic resin layer A for lamination using a lip coater, and dried at 80°C for 20 minutes to prepare a laminate composed of the ther...

Embodiment 2

[0524]

[0525] The polarizing plates 301 and 302 were fabricated by the following steps.

[0526] Step 1: A PET film having a film thickness of 100 μm was bonded as a separator to the hydrophilic polymer layer side of the stretched laminate 1 having the polarizing film (A) prepared above via an adhesive.

[0527] Step 2: Peeling the thermoplastic resin layer A from the stretched laminate 1 .

[0528] Process 3: The polarizing film (A) with a separator was immersed in the polyvinyl alcohol adhesive agent tank of 2 mass % of solid content for 1 to 2 second.

[0529] Step 4: Gently wipe off the excess adhesive attached to the polarizing film (A) with separator in Step 3, and then, the hydrophilized cellulose ester film 105-3 produced in Example 1 and The hydrophilized surface of 107 is arranged on the polarizing film (A).

[0530] Step 5: Apply the laminated film in step 4 to a pressure of 20-30N / cm 2 , The conveying speed is about 2m / min.

[0531] Step 6: The sample produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com